Wet flue gas desulphurization process for carbide slag slurry pretreatment

A technology of wet flue gas desulfurization and calcium carbide slurry, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles to achieve the effects of improving gypsum quality, reducing content, and shortening oxidation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

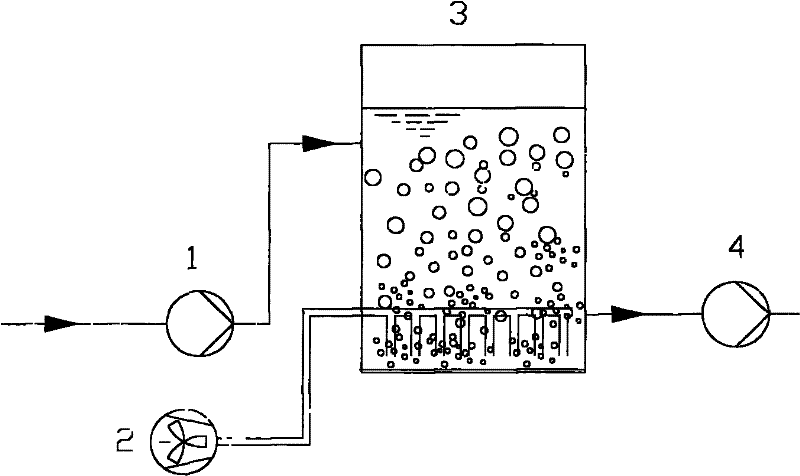

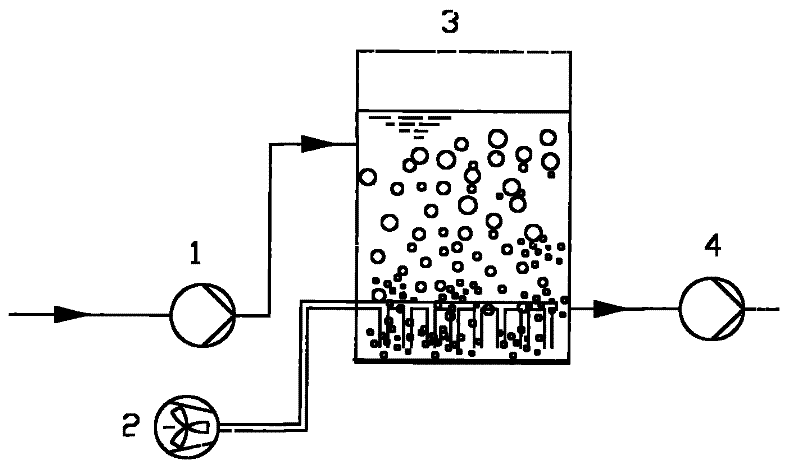

Method used

Image

Examples

Embodiment 1

[0017] A 220t / h coal-fired furnace in a thermal power plant adopts calcium carbide slag / gypsum wet desulfurization process for desulfurization, and the flue gas volume is 210,000m 3 / h, the concentration of sulfur dioxide at the inlet of the absorption tower is 2200mg / Nm 3 , using oxidation in the tower, using manganese sulfate as the catalyst, the catalyst concentration in the slurry storage tank is 0.5mmol / L, and the blast volume of the slurry storage tank is 3m 3 / m 3 h. The pH value is 5.7, and the design liquid-gas ratio is 8L / m 3 , the oxidation rate in the absorption tower is 47.3mmol / L·h, and the desulfurization efficiency is 95.7%. The moisture content of gypsum is lower than 8%, and the purity is higher than 96.5%.

Embodiment 2

[0019] A 2×75t / h coal-fired furnace in a chemical plant adopts calcium carbide slag / gypsum wet desulfurization process, with a flue gas volume of 310,000m 3 / h, the concentration of sulfur dioxide in the flue gas at the inlet of the absorption tower is 3100mg / Nm 3 , using copper sulfate and manganese sulfate as a composite salt of 1:2 (mass ratio) as a catalyst, the catalyst concentration in the slurry storage tank is 2mmol / L, and the blast volume of the slurry storage tank is 7m 3 / m 3 h. The pH value is controlled at 5.8, and the design liquid-gas ratio is 7L / m 3 , the desulfurization efficiency is 96.3%. Using external oxidation, the oxidation rate is 51.2mmol / L·h. The moisture content of gypsum is lower than 10%, and the purity is higher than 97.2%.

Embodiment 3

[0021] The coal-fired furnace of 2×135MW / h unit in a thermal power plant adopts calcium carbide slag / gypsum wet desulfurization process, and the flue gas volume is 1,200,000m 3 / h, the concentration of sulfur dioxide in the flue gas at the inlet of the absorption tower is 1700mg / Nm 3 , the design liquid-gas ratio is 6L / m 3 , using manganese sulfate as the catalyst, the catalyst concentration in the slurry storage tank is 10mmol / L, and the blast volume of the slurry storage tank is 8m 3 / m 3 ·h, the pH value is controlled at 5.5, the desulfurization efficiency is 98.7%. Oxidation in the tower is adopted, and the oxidation rate in the absorption tower is 48.8mmol / L·h. The moisture content of gypsum is less than 9%, and the purity is greater than 96.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com