Post-processing method for obtaining large-grain high-quality perovskite thin film and application thereof

A post-processing, perovskite technology, applied in semiconductor devices, electrical components, photovoltaic power generation, etc., can solve the problems of perovskite film surface morphology changes, prone to pinholes, small particle size, etc., and achieve oxidation time The effect of shortening, reducing the impact of device performance, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

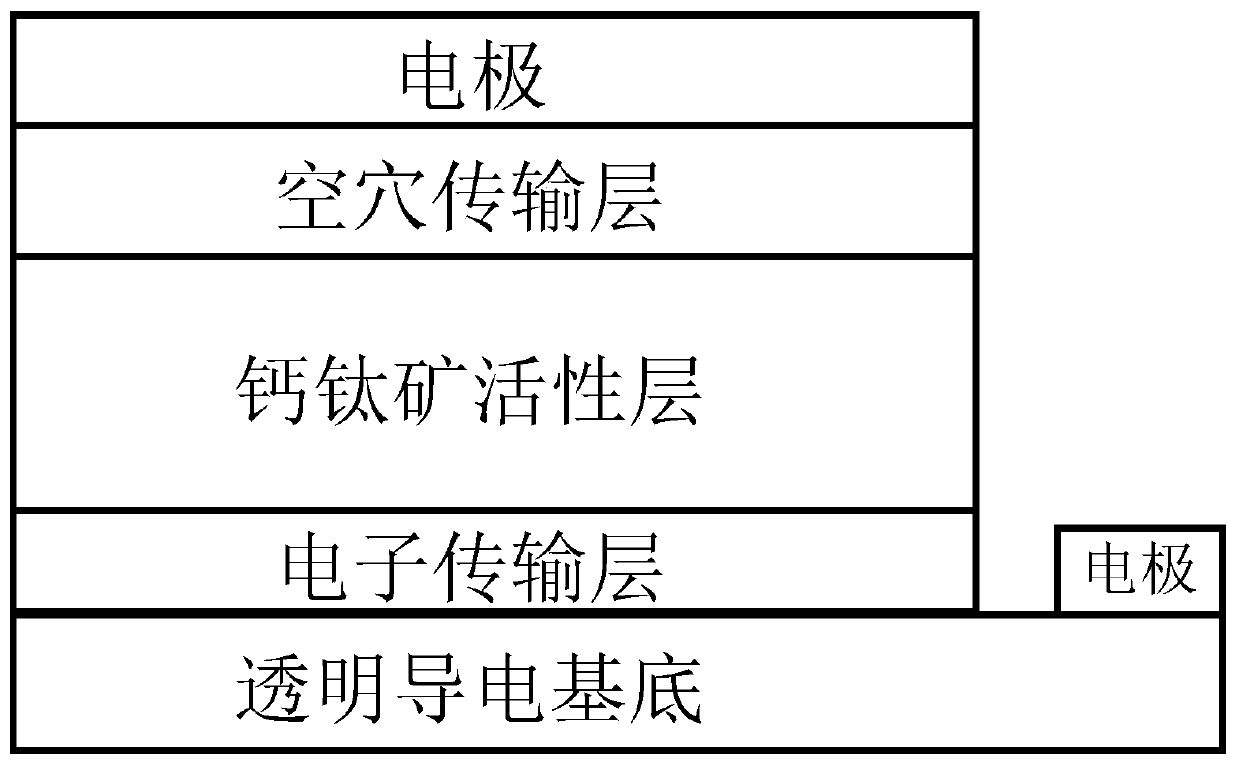

[0041] The battery structure of this implementation example is as figure 1 As shown, it includes five parts: substrate, electron transport layer, perovskite layer, hole transport layer and back electrode. The thickness of the perovskite layer is about 360nm, and the hole transport layer is about 150nm. The specific preparation process is as follows:

[0042] (1) Cleaning and processing the substrate. Use detergent, deionized water, ethanol, acetone, isopropanol, and ethanol to ultrasonically clean for 15 minutes, then dry the substrate with nitrogen, and then treat it with UV-ozone for 15 minutes to obtain SnO 2 base.

[0043] (2) Configure and prepare SnO 2 Spin coater. The mass fraction that will be purchased is 20wt% SnO 2 Take an appropriate amount of the aqueous colloid solution in a clean glass bottle, add deionized water at a ratio of 1:7.35 for dilution, and then oscillate ultrasonically for 30 minutes. The well-mixed diluted solution is then filtered through a fi...

Embodiment 2

[0054] The battery structure of this implementation example is as figure 1 As shown, it includes five parts: substrate, electron transport layer, perovskite layer, hole transport layer and back electrode. The thickness of the perovskite layer is about 520nm, and the hole transport layer is about 150nm. The specific preparation process is as follows:

[0055] (1) Cleaning and processing the substrate. Use detergent, deionized water, ethanol, acetone, isopropanol, and ethanol to ultrasonically clean for 15 minutes, then dry the substrate with nitrogen, and then treat it with UV-ozone for 15 minutes to obtain SnO 2 base.

[0056] (2) Configure and prepare SnO 2 Spin coater. The mass fraction that will be purchased is 20wt% SnO 2 Take an appropriate amount of the aqueous colloidal solution in a clean glass bottle, dilute it with deionized water at a ratio of 1:7, and then vibrate ultrasonically for 30 minutes. The well-mixed diluted solution is then filtered through a filter....

Embodiment 3

[0067] The battery structure of this implementation example is as figure 1 As shown, it includes five parts: substrate, electron transport layer, perovskite layer, hole transport layer and back electrode. The thickness of the perovskite layer is about 520nm, and the hole transport layer is about 150nm. The specific preparation process is as follows:

[0068] (1) Cleaning and processing the substrate. Use detergent, deionized water, ethanol, acetone, isopropanol, and ethanol to ultrasonically clean for 15 minutes, then dry the substrate with nitrogen, and then treat it with UV-ozone for 15 minutes to obtain SnO 2 base.

[0069] (2) Configure and prepare SnO 2 Spin coater. The mass fraction that will be purchased is 20wt% SnO 2 Take an appropriate amount of the aqueous colloidal solution in a clean glass bottle, dilute it with deionized water at a ratio of 1:7, and then vibrate ultrasonically for 30 minutes. The well-mixed diluted solution is then filtered through a filter....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com