Sample pretreating method for metal content analysis

A sample pretreatment and metal technology, which is applied in the preparation of test samples, etc., can solve the problems of long oxidation process, serious environmental pollution, and large safety hazards, and achieve shortened pretreatment time, safe operation, and low environmental pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

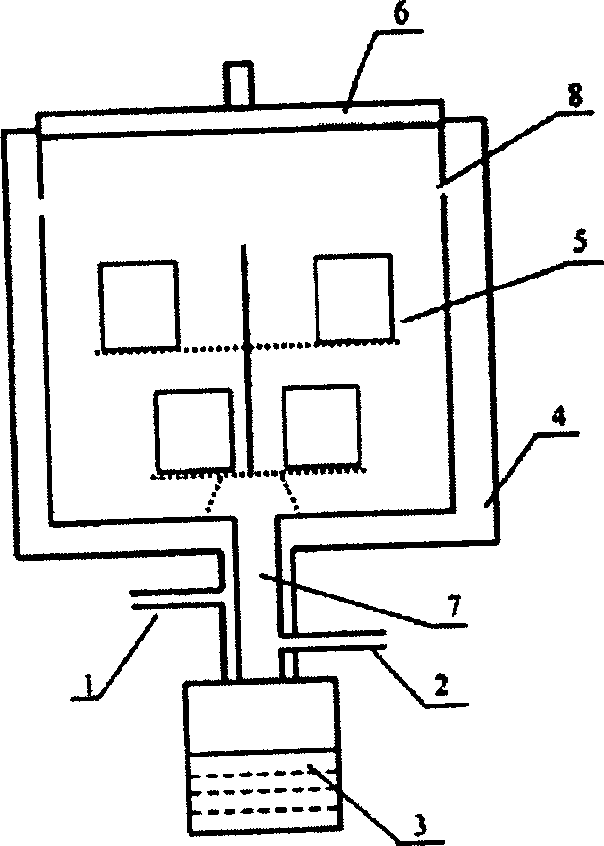

[0026] Weigh a certain amount of oil sample and place it in a quartz beaker, put the beaker into figure 1shown in the sample processing apparatus. Nitrogen gas was introduced into the heating furnace 4 from the gas inlet 1 at a flow rate of 2 liters / minute, and at the same time, the temperature of the heating furnace was raised to 600° C. at a temperature increase rate of 10° C. / minute. During the temperature program heating process, the volatile matter in the beaker is evaporated in order of boiling point from low to high, and turns into oil vapor, and is carried by nitrogen into the oil and gas outlet pipe 7, and condenses after exchanging heat with cold imported nitrogen. , flows into the waste oil bottle 3 along the pipe wall, and the nitrogen gas is discharged from the heating furnace through the gas outlet 2, and the non-volatile metal compounds and the generated coke-like substances remain in the beaker. After the furnace temperature rises to 600°C, continue to flow ni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com