Modified HCNG fuel preparation method and preparation system

A fuel preparation and modification technology, which is applied in fuel, gas fuel, petroleum industry, etc., can solve the problems of being easily affected by climate, slow flame propagation rate, and high emission of unburned hydrocarbons, so as to broaden the combustible mixing ratio, Low cost and emission reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with specific embodiment, further illustrate the present invention. But these examples are only for illustrating the present invention and are not intended to limit the protection scope of the present invention.

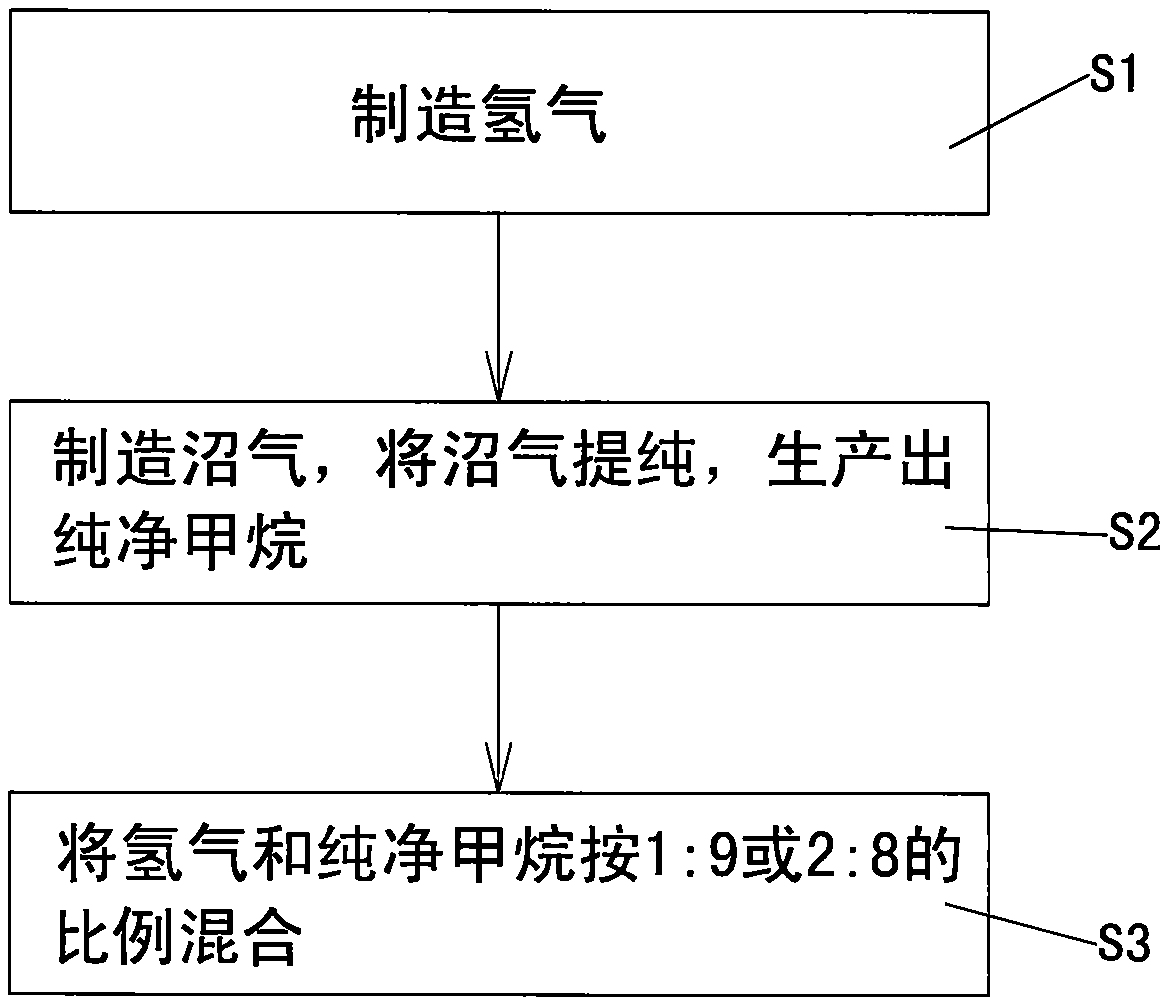

[0033] Such as figure 1 Shown, the modified HCNG fuel preparation method of the present invention comprises the steps:

[0034] S1. Production of hydrogen. In this step, hydrogen is produced by energizing the fuel cell with water or by methane and water vapor. Hydrogen is produced by energizing the fuel cell. The fuel cell is a PEM, SOFC, DMFC fuel cell, and the fuel cell is cracked to produce hydrogen. hydrogen;

[0035] In addition, hydrogen can also be produced from biogas, using biogas as raw material, and converting water steam to produce hydrogen-rich mixed gas; it uses a mature one-stage furnace gas production process in the field of synthetic ammonia production, which includes two steps: biogas desulfurization and hydrocarbons S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com