Oil-saving emission reduction device of gasoline-powered automobile and application method thereof

An automobile and fuel technology, which is applied in the charging system, combustion engine, internal combustion piston engine, etc., to achieve the effect of saving fuel consumption, reducing pollution emissions, and increasing power output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] After Ni is melted in a vacuum induction furnace, La is added under the protection of argon with a pressure of 0.03MPa, and when all the materials are melted, it is poured to make LaNi. 5 hydrogen storage alloys;

[0025] After the hydrogen storage alloy is mechanically crushed, it is placed in the hydrogen storage tank and filled, and the hydrogen gas is introduced into the hydrogen storage tank with a hydrogen cylinder; the time for the first filling of hydrogen gas is 30~50h, and the hydrogen storage alloy is activated during this process. Automatically crushed into fine particles; when hydrogen is charged again later, the time is controlled at 0.5~2h to reach 50~80% of the total hydrogen absorption capacity of the hydrogen storage alloy; after the completion of hydrogen charging, the equilibrium hydrogen pressure of the hydrogen storage alloy in the hydrogen storage tank is at 0.1~0.5MPa;

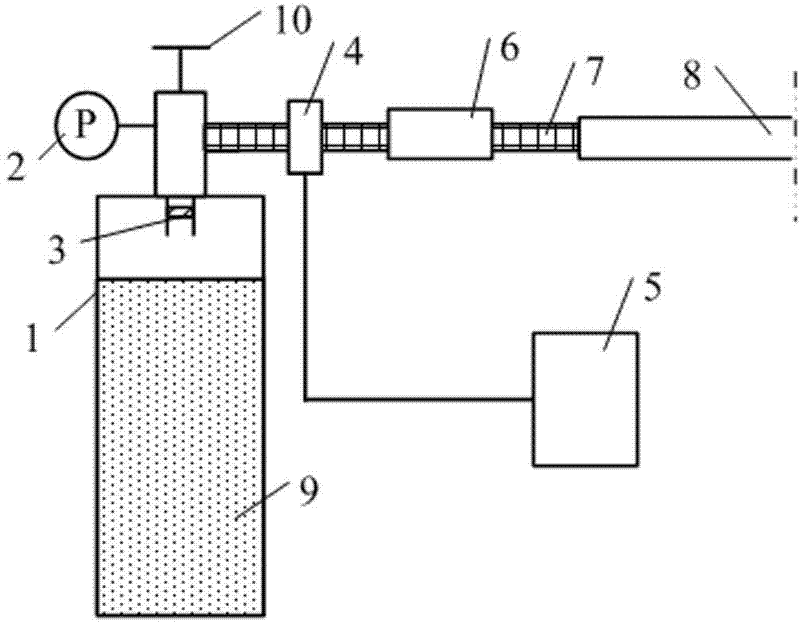

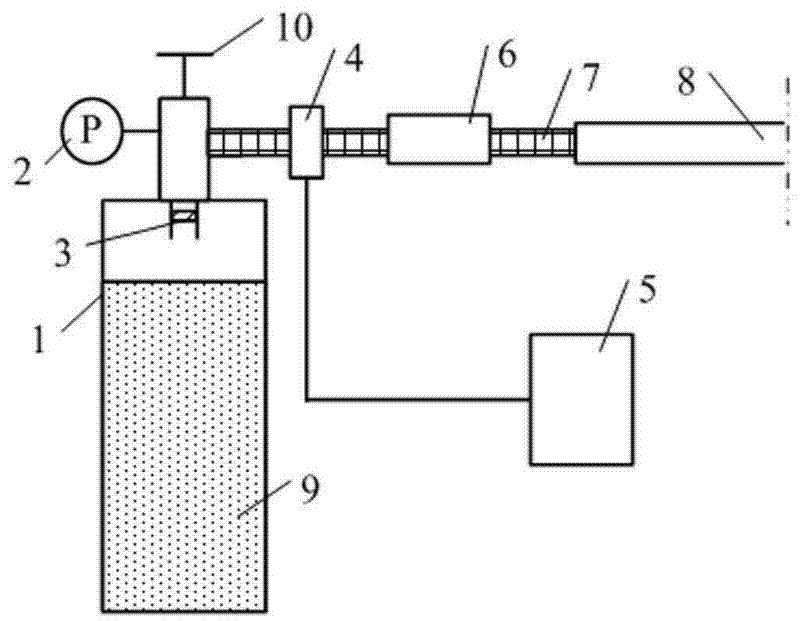

[0026] Assemble the filled hydrogen storage tank, hydrogen pipeline, oil pu...

Embodiment 2

[0034] The hydrogen storage alloy is the same as in Example 1; the method of filling hydrogen is the same as in Example 1; the hydrogen storage tank after hydrogen charging, the hydrogen pipeline, the oil pump relay of the fuel vehicle and the intake manifold of the engine are assembled together, and the method is the same as in the example 1. The difference lies in:

[0035] The hydrogen storage tank is made of steel;

[0036] The hydrogen pipeline is stainless steel pipe;

[0037] The flow controller selects the control hole;

[0038] The application method is the same as in Example 1, except that the flow rate of hydrogen in the hydrogen pipeline is controlled to be 200mL / min;

[0039] A car equipped with a gasoline engine was used for the test, and the driving distance was 496 kilometers. Compared with the traditional method without hydrogen, the gasoline was saved by 14%, and the total emissions of carbon monoxide, carbon dioxide, hydrocarbons and suspended particles we...

Embodiment 3

[0041] Vacuum melting to make MmNi 5 Hydrogen storage alloy (Mm is mixed rare earth);

[0042] The hydrogen storage alloy is mechanically crushed and placed in the hydrogen storage tank to fill it up, the method is the same as in Example 1; the hydrogen storage tank after hydrogen filling is assembled with the hydrogen pipeline, the oil pump relay of the fuel vehicle and the engine intake manifold, and the method is as follows: With embodiment 1, difference is:

[0043] The hydrogen storage tank is made of resin reinforced metal material;

[0044] The flow controller selects the control hole;

[0045] The application method is the same as in Example 1, except that the flow rate of hydrogen in the hydrogen pipeline is controlled to be 100mL / min;

[0046]A medium bus equipped with a diesel engine was used for the test, and the driving distance was 496 kilometers. Compared with the traditional method without hydrogen, the diesel fuel was saved by 13%. The emission tester was u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com