Direct initiation device under two different ventilation modes and test method

A detonation device, a direct technology, applied in the direction of combustion method, material explosiveness, ignition by electric spark, etc., can solve the problems of large ignition energy, increase system complexity, large engineering cost, etc., to reduce detonation ignition energy and reduce distance , Improve the effect of explosion pressure and velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

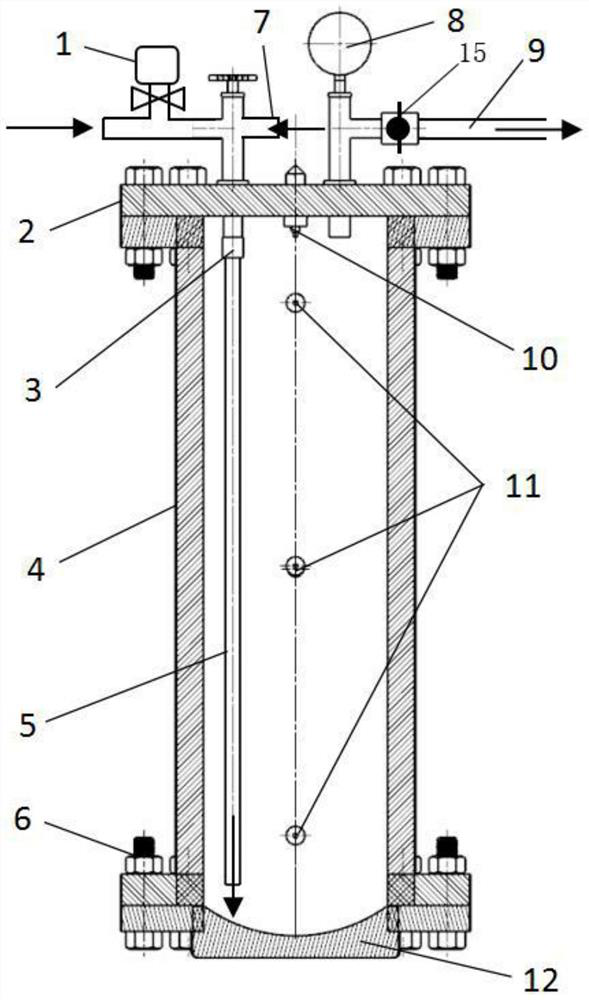

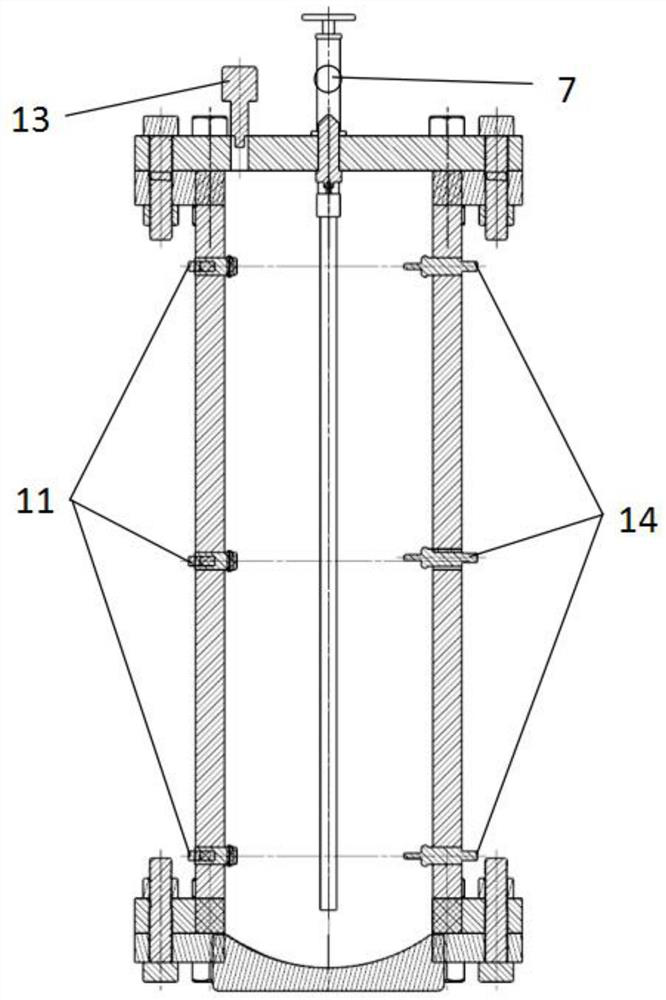

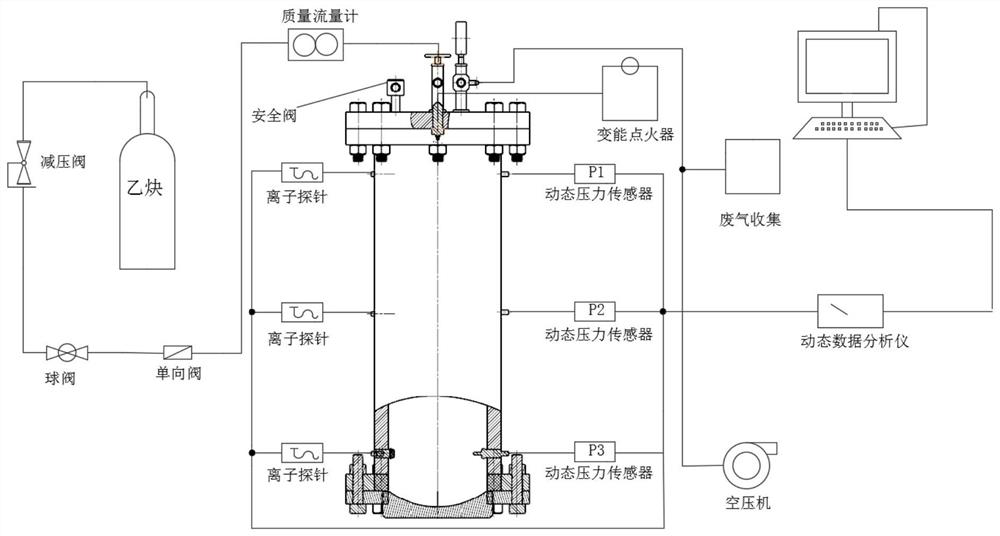

[0042] Using the air flow of the air compressor to pass the powder into the device will increase the change of the initial pressure in the device, so the first step is to test the influence of the change of the initial pressure on the detonation parameters.

[0043]The device and material parameters used in the test are as follows: the volume of the experimental device is V=20.09L, the inner diameter is d=180mm, the distance between adjacent sensors / ion probes is L=225mm, and the ignition energy E=0.2J. The experiment was carried out under airtight conditions, the reaction medium was 99.9% high-purity acetylene, and the combustion aid was air. During the experiment, the volume of acetylene injected once was 2.04L (equivalent ratio η≈1).

[0044] Table 1 Detonation theoretical parameters of acetylene-air mixture

[0045]

[0046] As shown in Table 1, the detonation pressure and detonation velocity of the acetylene-air mixture reaching the theoretical detonation state solved ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com