Fuel modifiers for natural gas reciprocating engines

a technology of natural gas reciprocating engine and fuel modifier, which is applied in the direction of fuel additives, gaseous fuels, petroleum industry, etc., can solve the problems of increasing the cost of maintaining existing spark natural gas engines, increasing the cost of sparking, and increasing so as to reduce the knocking tendency of engines, increase engine performance and efficiency, and reduce the effect of ignition energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

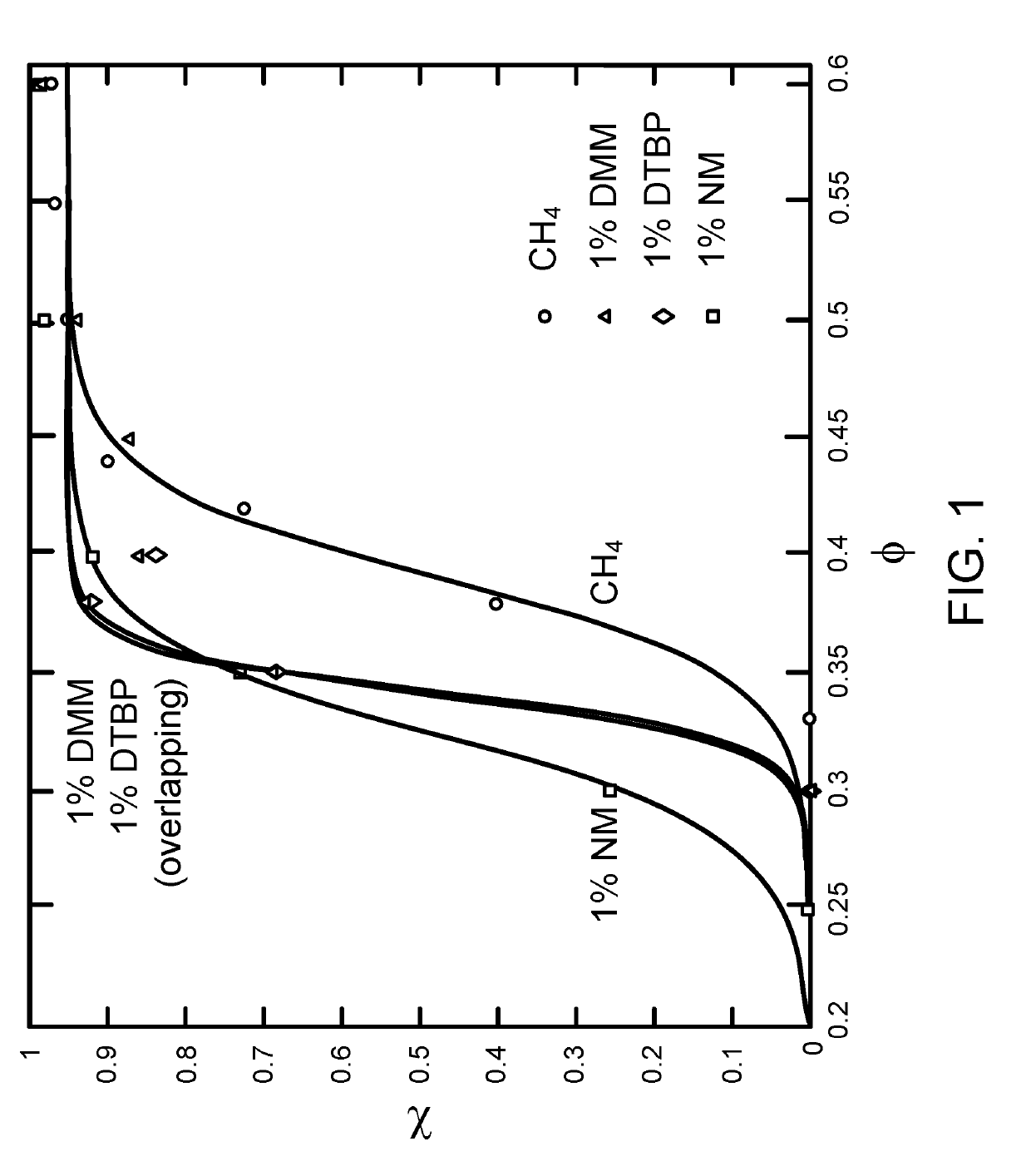

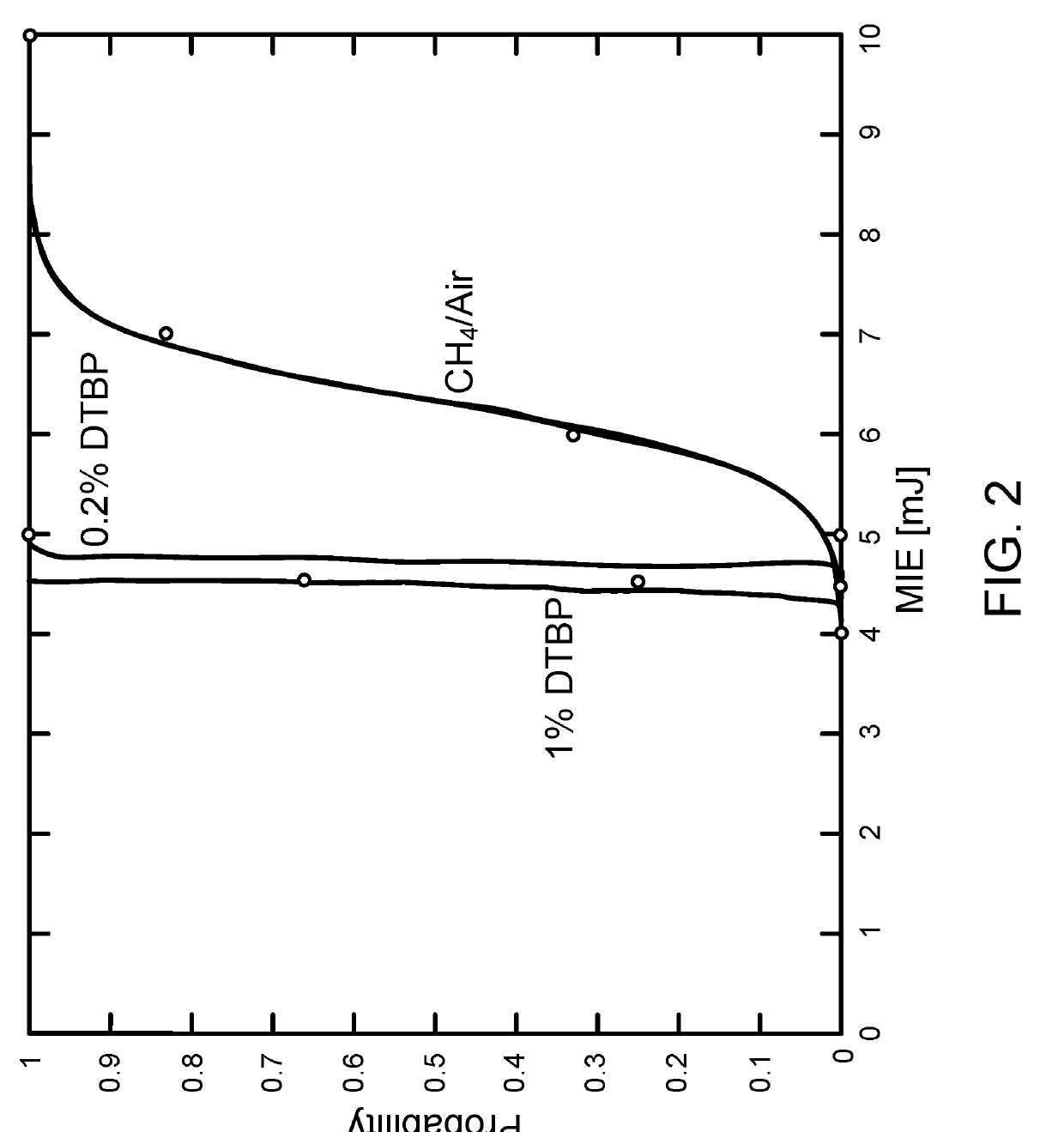

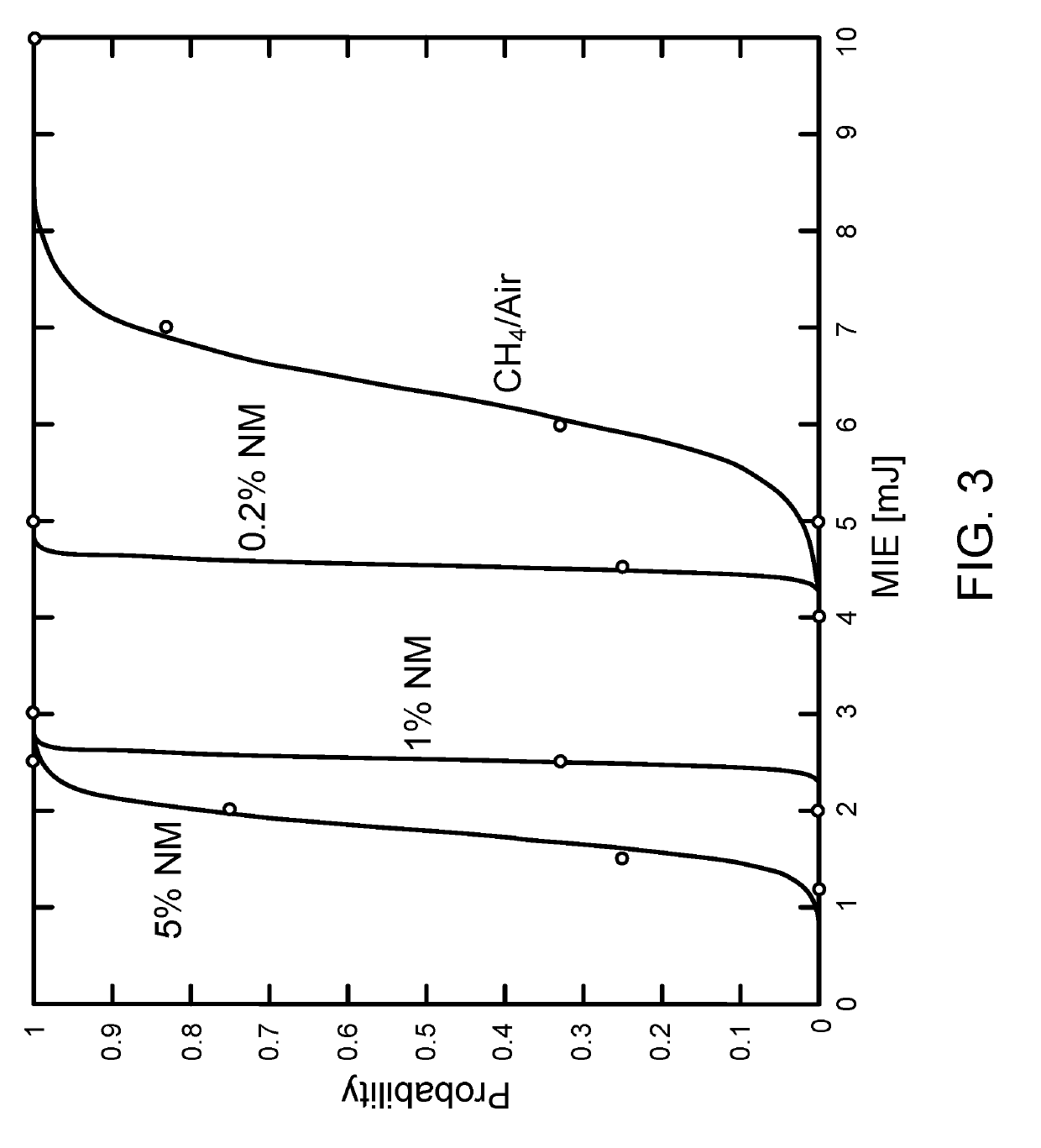

[0062]Methane / air mixtures and methane / fuel modifier mixtures were ignited via laser ignition at elevated pressures and temperatures for conditions representative of internal combustion engines. The experiments measured the lean limit and minimum ignition energy at the different test conditions.

[0063]A rapid compression machine (RCM) was used to simulate the rapid pressure and temperature rises typical of internal combustion engines and a Nd:YAG laser was employed as the ignition source. RCMs are traditionally used for fuel characterization and chemical kinetics studies of hydrocarbons spanning from simple fuels like methane to larger species in the diesel range.

[0064]The construction and operation of the RCM is further described in two publications. (See, “Laser Ignition of Methane-Air Mixtures with a Rapid Compression Machine” 53rd AIAA Aerospace Sciences Meeting, Jan. 5, 2015, eISBN: 978-1-62410-343-8). (See also, “Fundamental Studies of Laser Ignition of Natural Gas / Air Mixtures...

PUM

| Property | Measurement | Unit |

|---|---|---|

| combustion efficiency | aaaaa | aaaaa |

| combustion efficiency | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com