Low NOx oil gun device heated by backheating

A technology of regenerative heating and oil gun, which is applied in the direction of lighting and heating equipment, solid fuel combustion, combustion ignition, etc., can solve the problems of insufficient stable combustion ability of small oil guns, unusable ignition of small oil guns, etc., and achieves ingenious design , overhaul and maintenance convenience, high reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

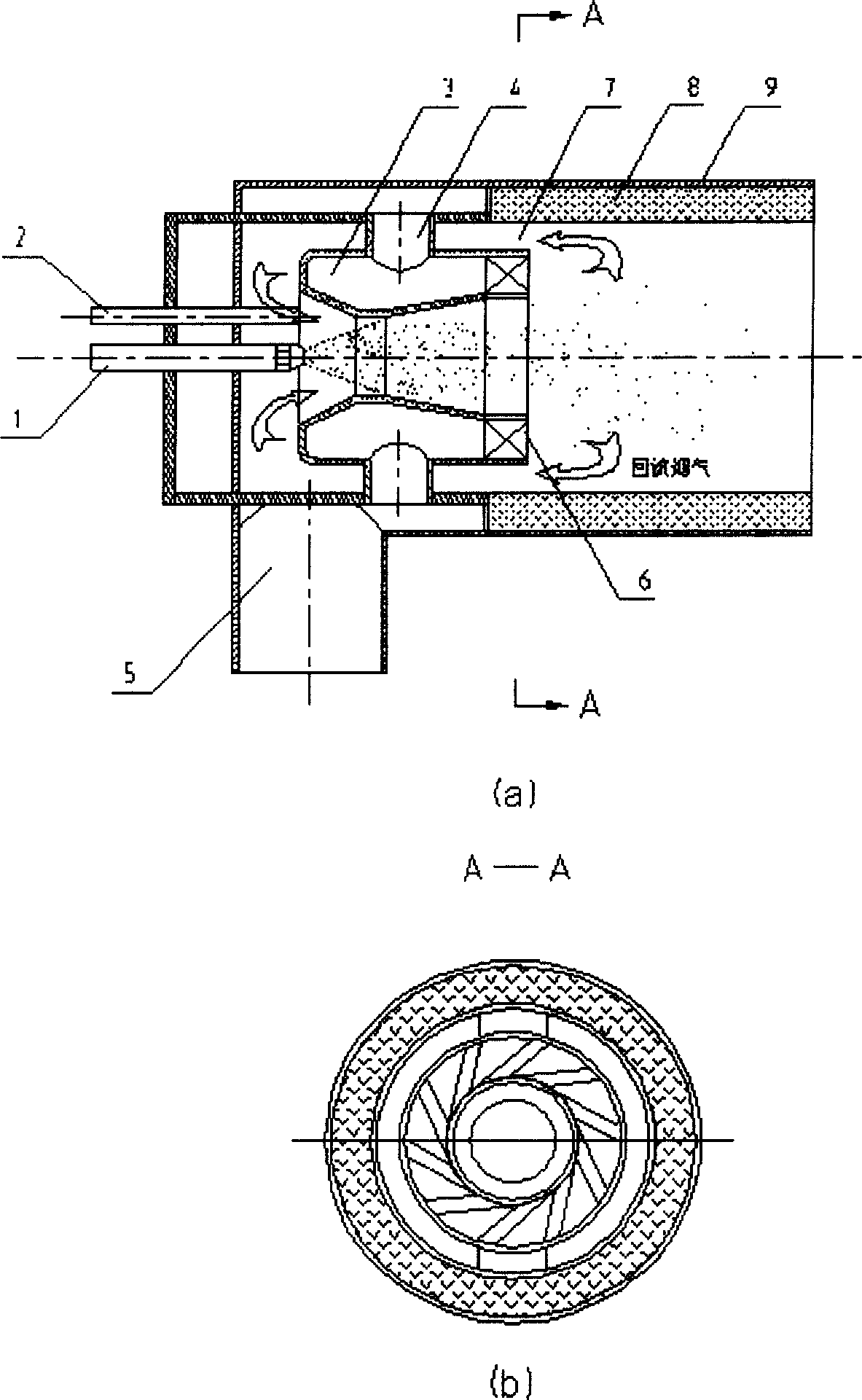

[0018] like figure 1 As shown, the low-NOx oil gun device using regenerative heating includes a micro oil gun 1, a high-energy ignition gun 2, a venturi air duct 3, a venturi air inlet duct 4, a total air inlet duct 5, a cyclone 6, a return The hot channel 7, the ceramic combustion chamber 8 and the outer casing 9, the outer casing 9 is provided with a ceramic combustion chamber 8, a cyclone 6, the cyclone 6 is connected with the venturi duct 3, and the venturi duct 3 is provided with a venturi The air inlet pipe 4 and the outer casing 9 are connected with the general air inlet pipe 5, and the inlet end of the venturi air duct 3 is provided with a micro oil gun 1 and a high-energy ignition gun 2.

[0019] The hot flue gas return flow rate of the oil combustion chamber at the rear end of the cyclone 6 is 2%-10% of the total flue gas amount. After the reflux hot flue gas and oil mist are mixed, the mixing temperature reaches 200℃-350℃. The ratio of the throat area of the ven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com