Double-preheating environmental protection combustor for tube heating furnace and applications thereof

A tubular heating furnace and double preheating technology, applied in burners, gas fuel burners, combustion methods, etc., can solve the problems of enlarging the flame combustion area and reducing the adiabatic combustion temperature of the combustion area, so as to reduce the combustion temperature, The effect of reducing operating costs and reducing exhaust gas temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

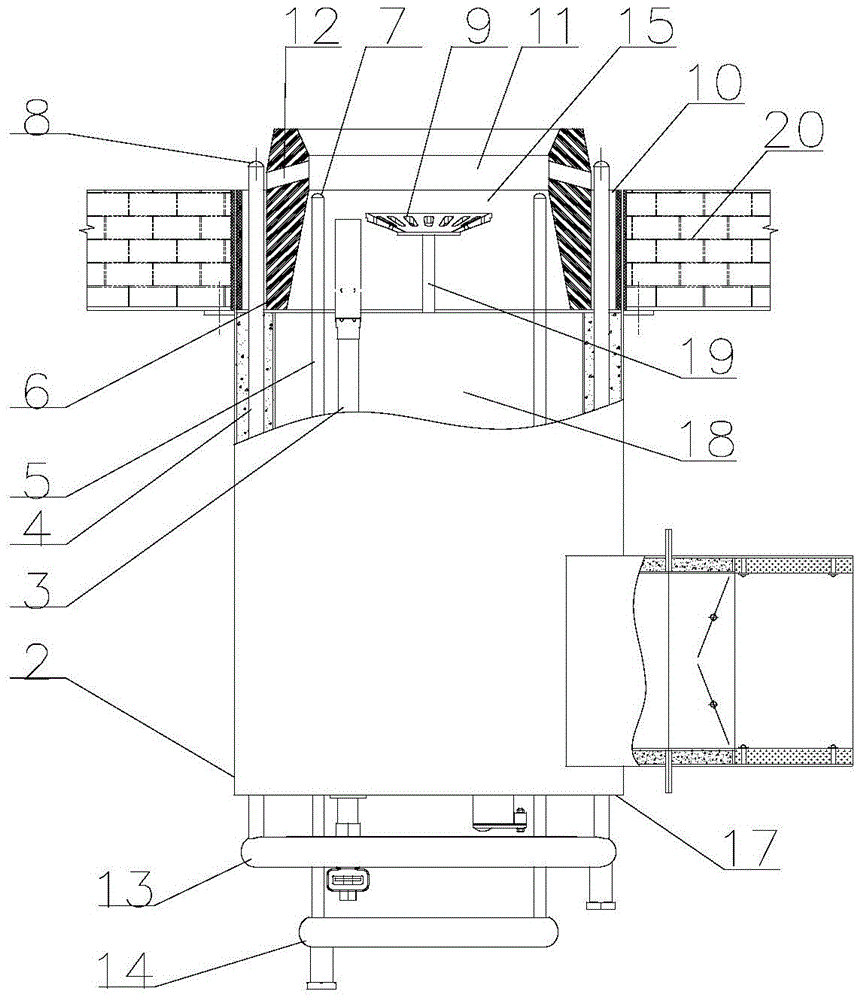

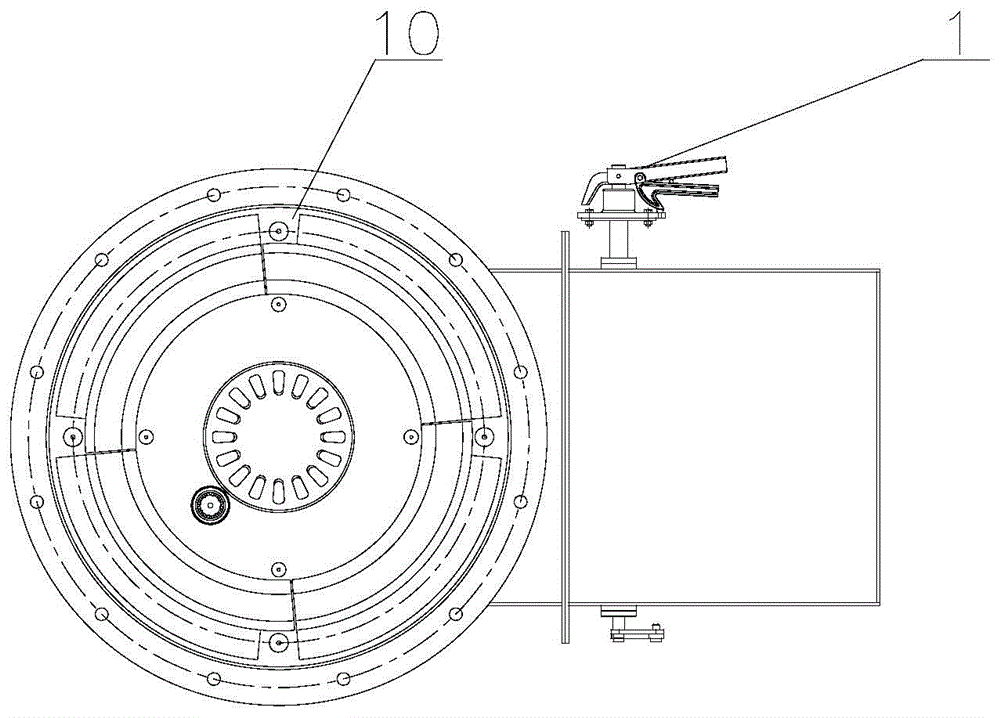

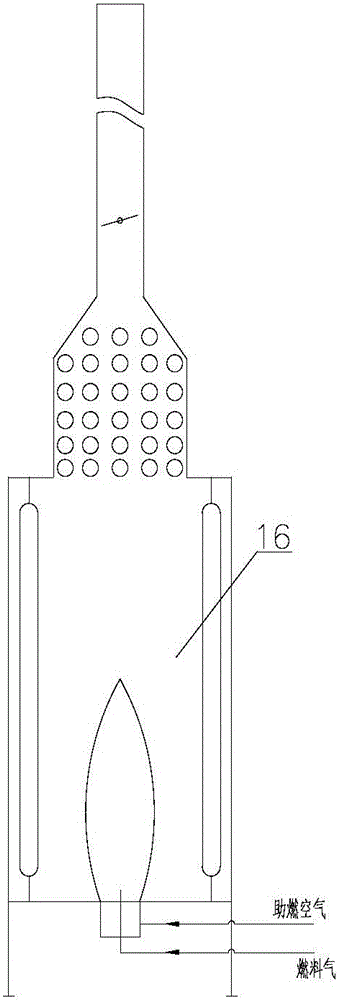

[0036] A double preheating environmental protection burner for a tubular heating furnace, the structure of which is as follows Figure 1-2 As shown, it mainly includes air duct butterfly valve 1, cylinder body 2, refractory brick 6, outer spray gun 4, inner spray gun 5, permanent lamp 3, flame stabilizing plate 9 and other parts. Set in the hearth 16 of the tube furnace, such as image 3 shown.

[0037] The burner duct butterfly valve 1 communicates with the barrel 2, and the inner passage is a high-temperature combustion air passage 19. Refractory bricks 6 are placed on the upper part of the cylinder body 2, and the internal fire channel 15 of the refractory bricks 6 is concentric with the cylinder body. A circular perforated plate, also can increase V-shaped or U-shaped folded perforated plate as required on the flame-stabilizing plate 9 . The flame stabilizing plate 9 is kept concentric with the cylinder body 2 and is located in the middle of the fire channel 14 .

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com