Biomass fuel pulse combustion hot blast device and use method thereof

A technology of hot air heating device and biomass fuel, which is applied in the combustion of solid fuel, combustion equipment, air heater, etc., can solve the problems of slagging, insufficient combustion of biomass fuel, ash accumulation, etc., and achieve good fuel combustion conditions. , the effect of a wide range of fuel sources and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with drawings and embodiments.

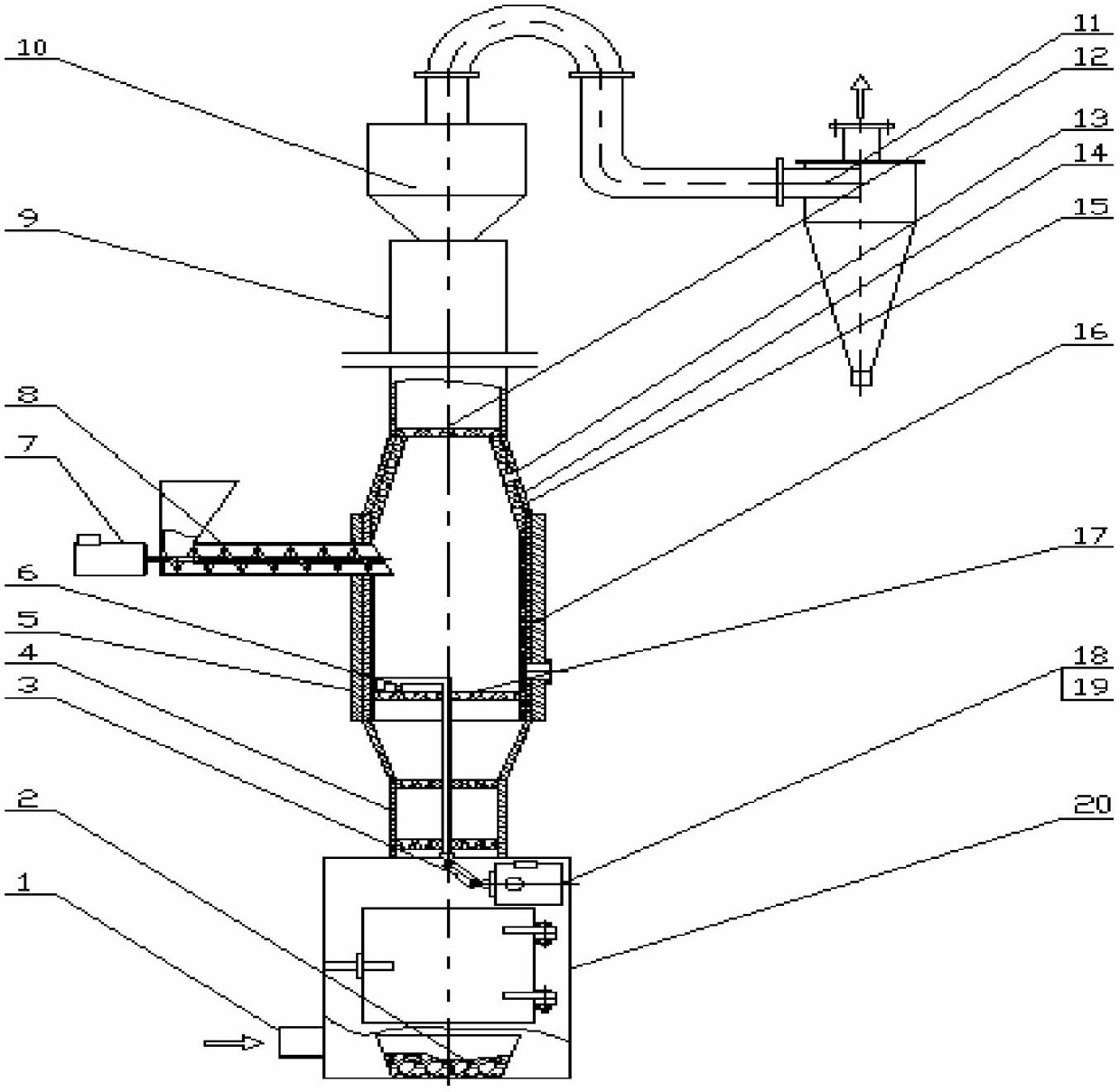

[0043] Such as figure 1 As shown, the device of the present invention includes an air inlet 1, an ash collecting bucket 2, a universal joint 3, a downwind pipe 4, an aluminum silicate hydrochloric acid insulation blanket 5, a rotating distribution rod 6, a feeding speed regulating motor 7, and a screw conveyor 8. Upper outlet duct 9, coupling chamber 10, cyclone separator 11, combustion-supporting net 12, supplementary air outlet 13, conical cylinder 14, high-temperature refractory layer 15, furnace cylinder 16, furnace grate 17, speed-regulating motor 18, relay 19. Base 20.

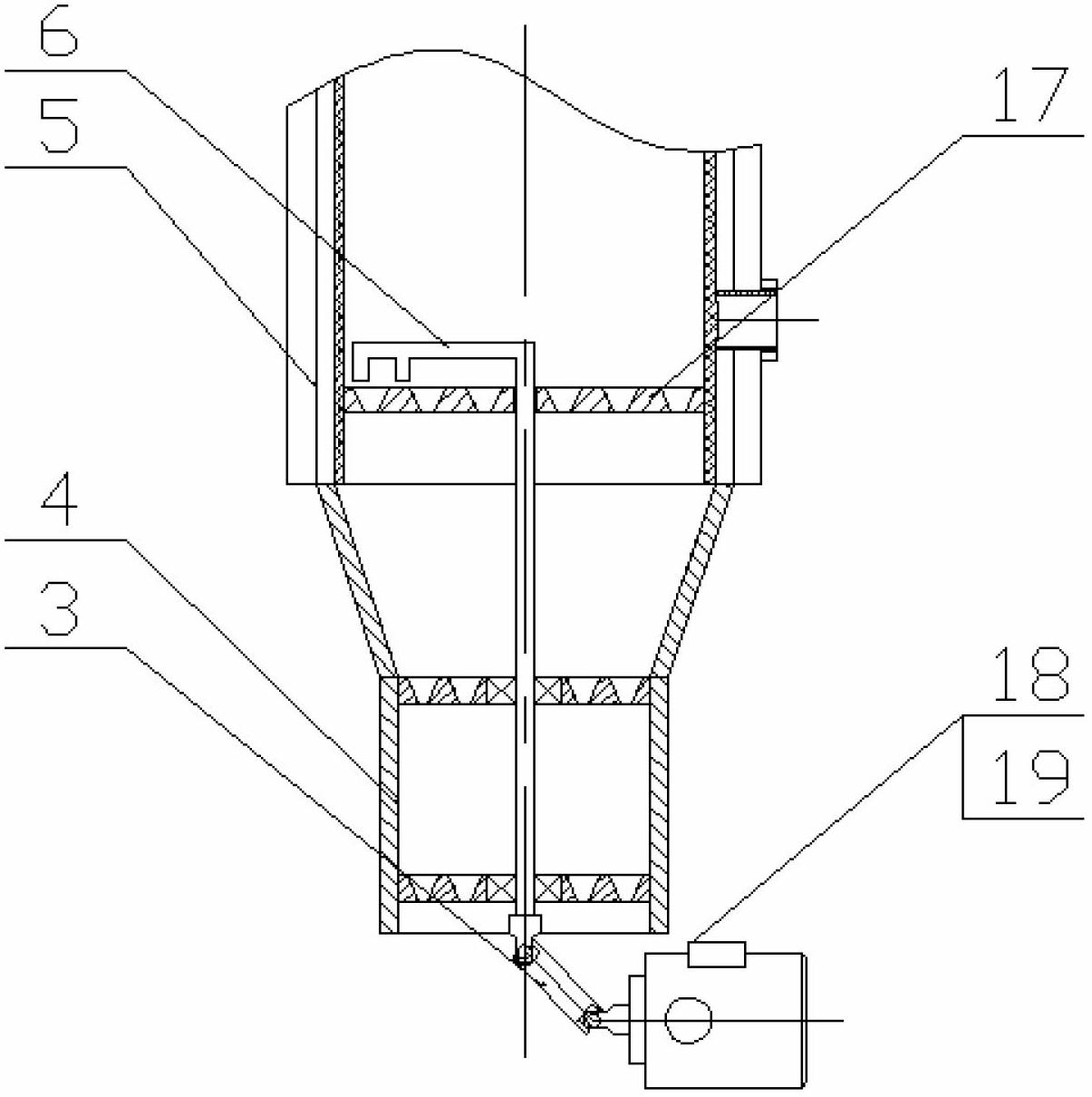

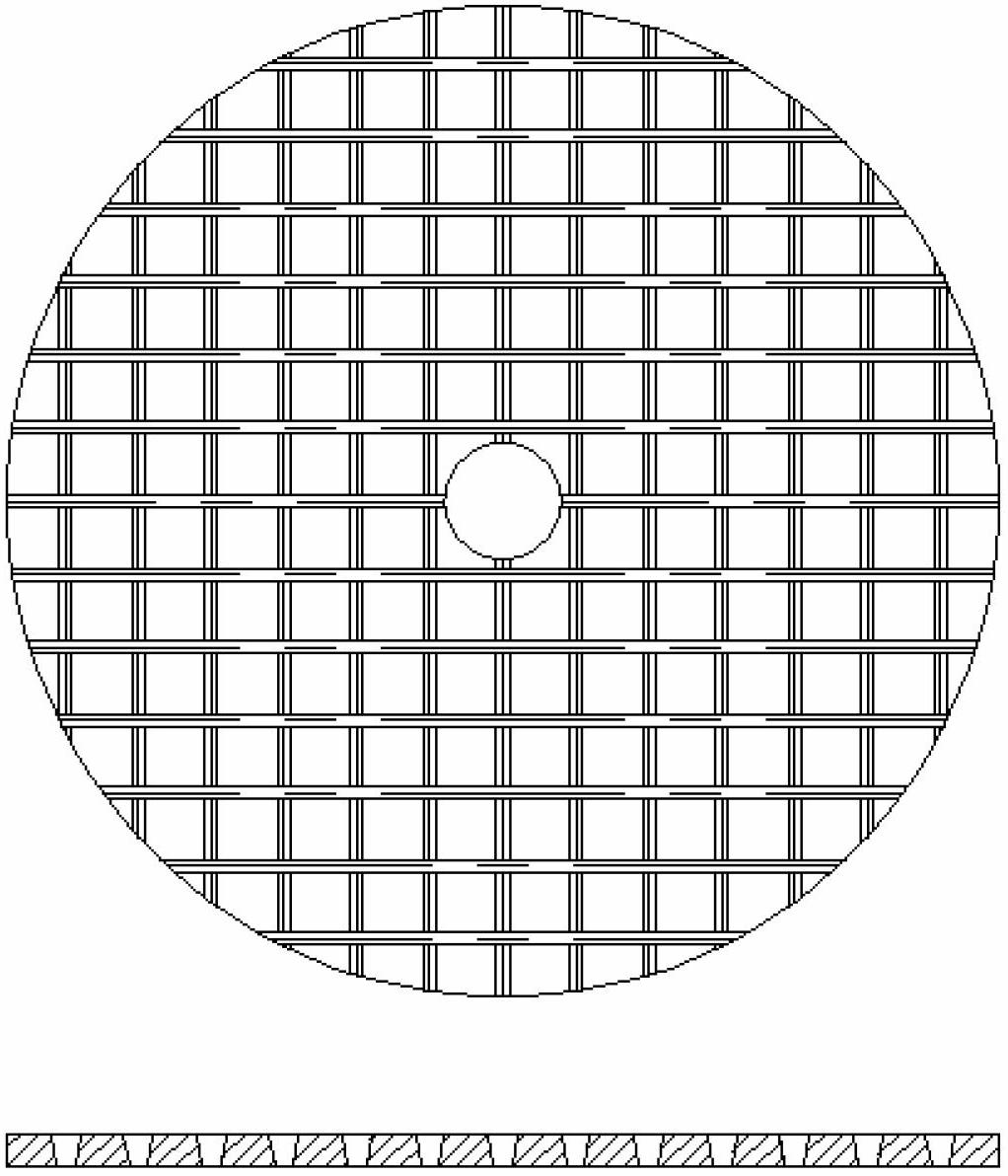

[0044] A Rick type pulsating burner main body is installed on the base 20 , and the pulsating burner main body includes a lower air duct 4 , a furnace cylinder 16 , a conical cylinder 14 and an upper air outlet duct 9 from bottom to top. A furnace grate 17 is installed in the furnace cylinder 16...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com