Spiral flow up jet premix and preheat burner with circuit and porous regenerator

A heat accumulator and ring technology, applied to gas fuel burners, burners, combustion methods, etc., can solve the problems of uneven distribution of combustion airflow, poor controllability, complex structure, etc., to reduce the air excess coefficient, improve Combustion temperature and combustion intensity, and the effect of simplifying the structure of the burner

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

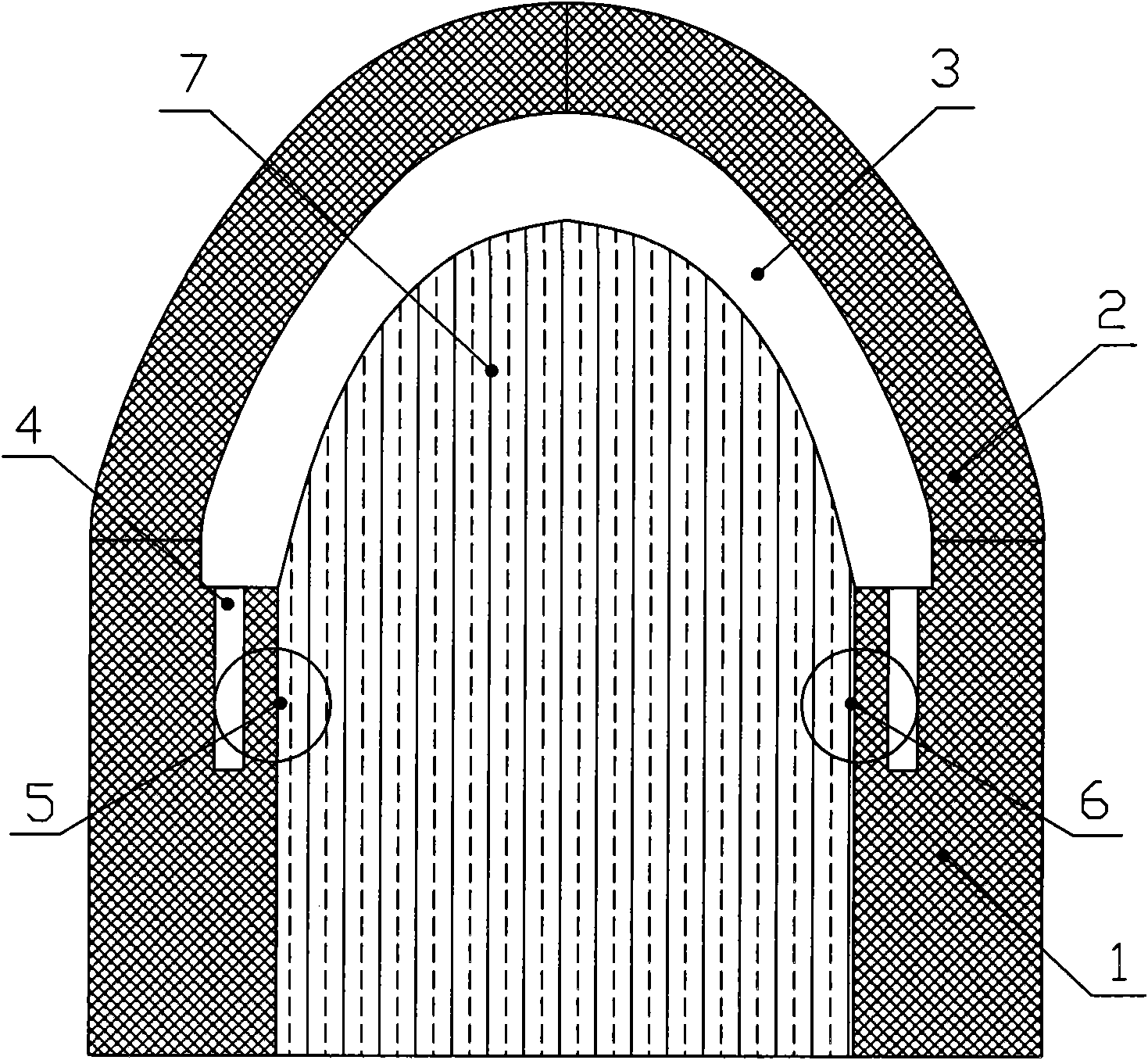

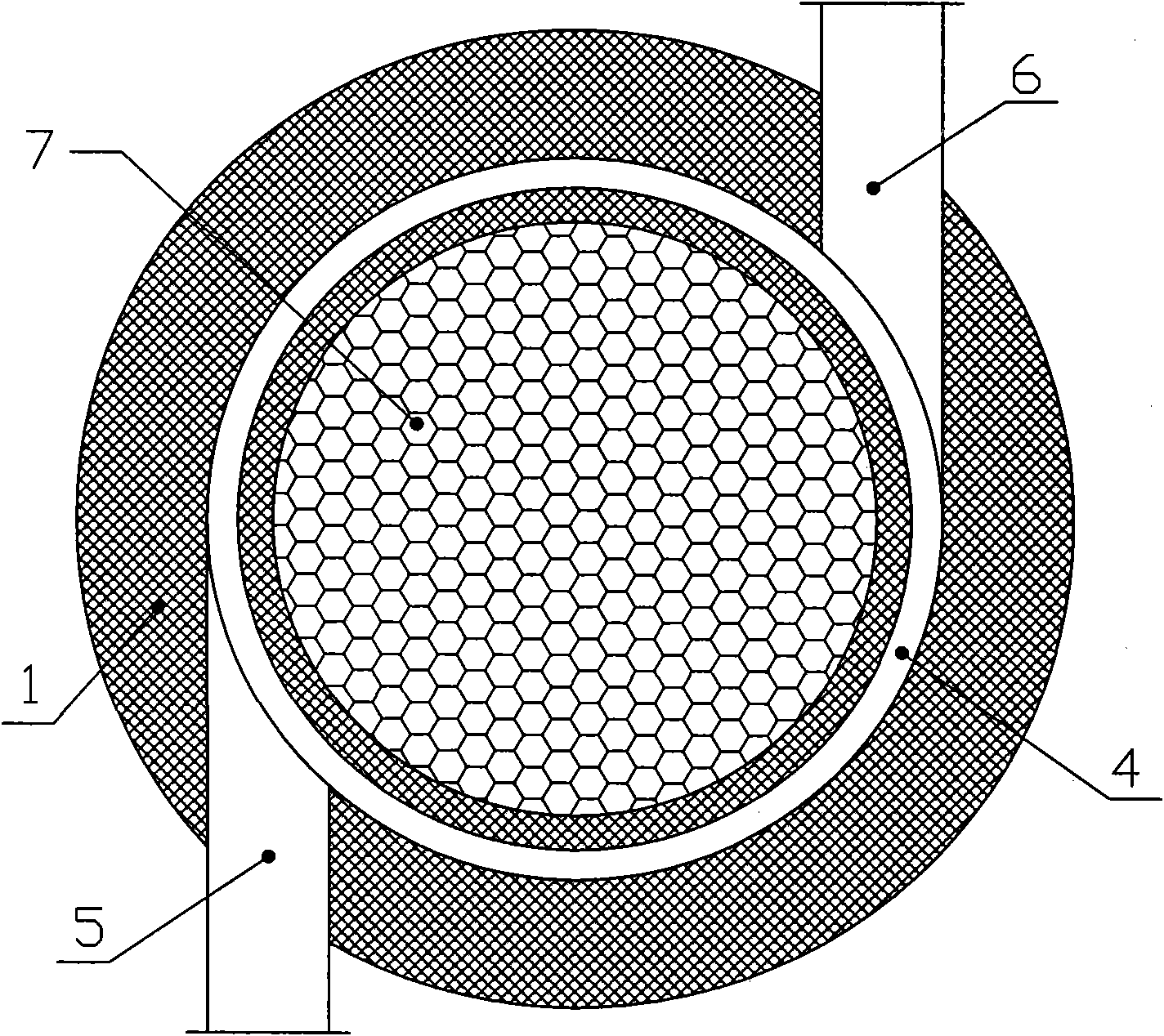

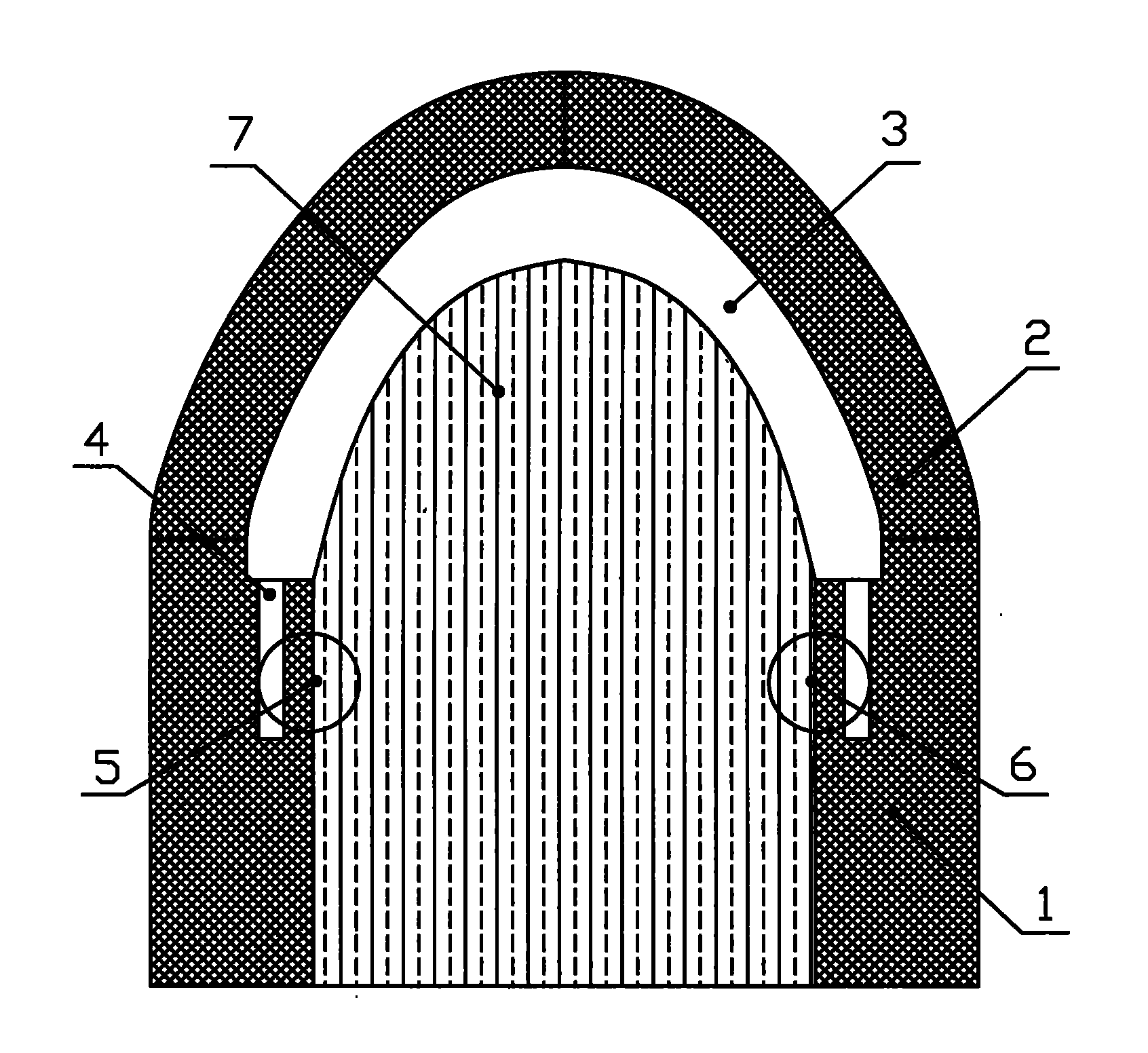

[0008] Depend on figure 1 , 2 Shown, the present invention comprises cylinder wall, dome and combustion chamber, and this burner is formed spherical dome cylinder shape lower opening together by cylinder wall 1, hemispherical or the dome 2 of inverted catenary rotation structure, The combustion chamber structure 3 that can make the air flow rotate and burn in it, the air flow primary mixing ring 4 with a rectangular cross-section with an upper opening is arranged annularly on the inner wall of the cylindrical wall 1, and the gas inlet pipe 5 and the air inlet pipe 5 arranged symmetrically are connected with the rotary cut. The intake pipe 6 and the combustion chamber structure 3 are filled with a porous regenerator 7, which is made of refractory balls, checker bricks with different apertures, or a honeycomb ceramic structure. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com