Equipment for continuously welding circular welds

A technology of annular welding seam and equipment, applied in the field of annular welding equipment, can solve the problems of unsatisfactory welding effect, porosity, virtual welding, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

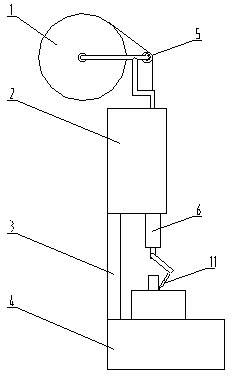

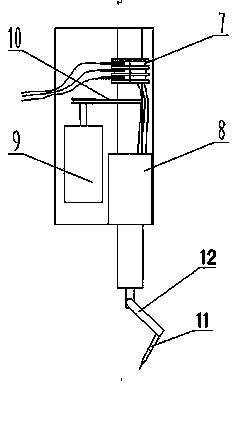

[0009] Depend on figure 1 Known, a kind of equipment of uninterrupted welding annular weld, consists of welding wire winch 1, hydraulic power control cabinet 2, column 3, workbench 4, welding wire guide wheel 5, welding torch main shaft 6, electric slip ring 7, hydraulic cylinder 8, motor 9. The belt 10 and the welding torch head 11 are composed of the welding wire winch 1, the welding wire guide wheel 5 and the welding torch head 11 are installed on the welding torch main shaft 6 in the hydraulic power control cabinet 2, and the hydraulic power control cabinet 2 and the workbench 4 are fixed by the column 3 Together, 7 electric slip rings, 8 hydraulic cylinders, 9 motors, and belts 10 are the main electric hydraulic components inside the hydraulic power control cabinet 2. During work, the workpiece is fixed on the workbench, the power supply motor 9 drives the welding torch main shaft 6 to rotate through the belt 10, and the rotation of the welding wire and the welding torch ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com