Automatic welding machine and automatic welding method for double straight seams of radiator

An automatic welding machine and radiator technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of high cost, difficult assembly, complex structure, etc., achieve good welding quality, reduce welding deformation, and small size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

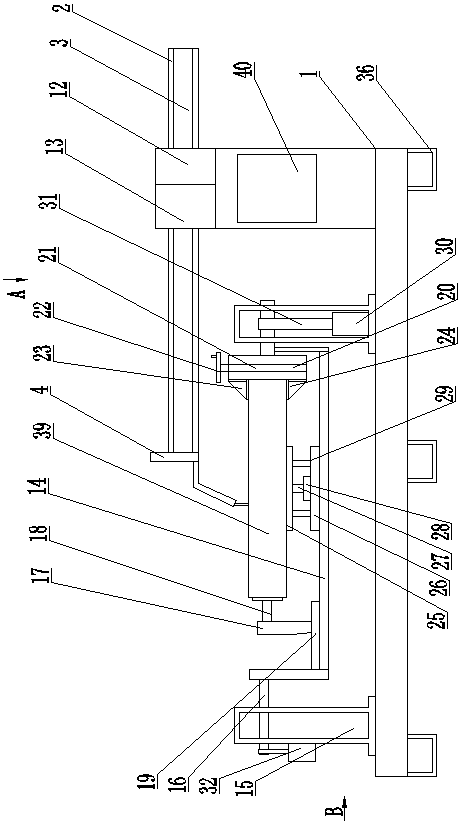

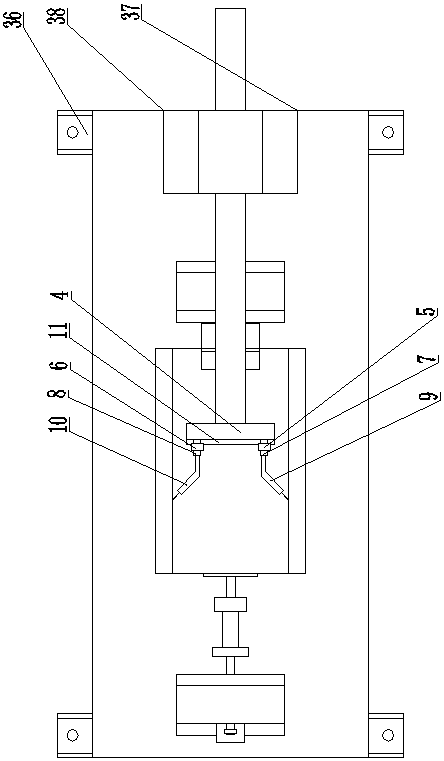

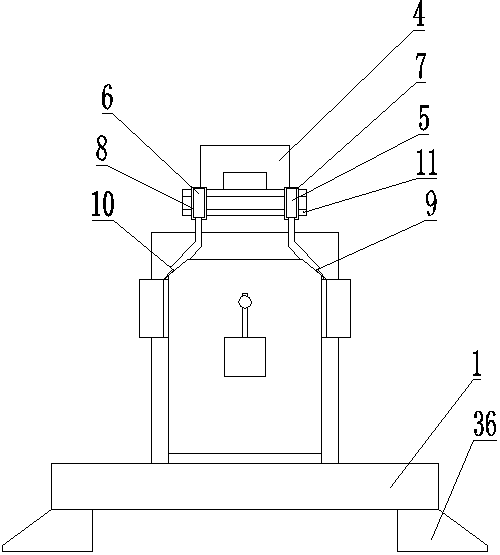

[0044] as attached figure 1 , 2 As shown in and 3, the radiator double straight seam automatic welding machine of the present invention has a structure comprising a frame 1, two welding torches, a controller 40, a double welding torch transverse walking device, a workpiece positioning device and a turning device, and the frame 1 includes a base 36 and the crossbeam 2 on the top, the controller 40 is connected to and controls the welding torch, the double welding torch lateral travel device, the workpiece positioning device and the overturning device, the overturning device is arranged above the base 36, the workpiece positioning device is arranged on the overturning device, and the overturning device can overturn the workpiece Positioning device, the double welding torch transverse traveling device is set on the beam 2, the workpiece positioning device is located under the double welding torch transverse traveling device, and the turning device is located on both sides of the ...

Embodiment 2

[0058] A radiator double straight seam automatic welding method, the method comprises the following steps:

[0059] (1) Complete the clamping and positioning of the left and right sides, front and rear sides, and upper and lower sides of the workpiece through the left positioning fixture, right positioning fixture and vertical positioning fixture of the workpiece positioning device;

[0060] (2) After the workpiece is positioned, the motor drive mechanism drives the double welding torch traveling device to move along the linear guide rail. The double welding torch traveling device drives the two welding torches to quickly walk to the starting point of the workpiece weld, and the two sets of welding torch lifting mechanisms respectively drive the two welding torches to drop quickly;

[0061](3) Send shielding gas, strike the arc, and move the two torches left and right respectively. After reaching the set length, close the arc and stop sending shielding gas;

[0062] (4) The mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com