Degradable super-tough silk protein-based material and preparation method and application thereof

A silk protein, protein-based technology, applied in the direction of single-component silk fibroin artificial filament, rayon manufacturing, textile and paper making, etc. Elongation and toughness, the effect of a wide range of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

[0056] Prepare the degradable super tenacious fibroin film according to the following method:

[0057] (1) As in Table 1, prepare silk protein solution, glycerin solution, and calcium chloride solution respectively, and mix the above-mentioned solutions according to the volumes in Table 1 after the preparation is completed. Take 3.5mL of the mixed solution and pour it into a petri dish with a diameter of 6mm, so that the solution completely covers the surface of the petri dish.

[0058] (2) The petri dish poured with the mixed solution was left open and dried at room temperature for 12 hours, and then the dried petri dish was placed in a vacuum drying oven and continued to dry for 2-4 hours at room temperature to prepare each silk protein film ( 15% glycerin + 5% calcium chloride; 15% glycerin + 10% calcium chloride; 20% glycerin + 5% calcium chloride; 20% glycerin + 10% calcium chloride).

[0059] The photo of the prepared silk protein film (20% glycerol+10% calcium chloride...

Embodiment 3

[0079] The degradation performance of the film obtained in Example 3 was characterized by the degradation performance in different enzyme solutions (protease XIV, collagenase and α-chymotrypsin). Cut the samples into 10mm×10mm squares and soak them in 2mL of different enzyme solutions. The remaining samples were weighed on the first day and the third day respectively, and the degradation rate of the samples in different enzyme solutions could be calculated. The results of the enzymatic degradation test were as Figure 6 shown.

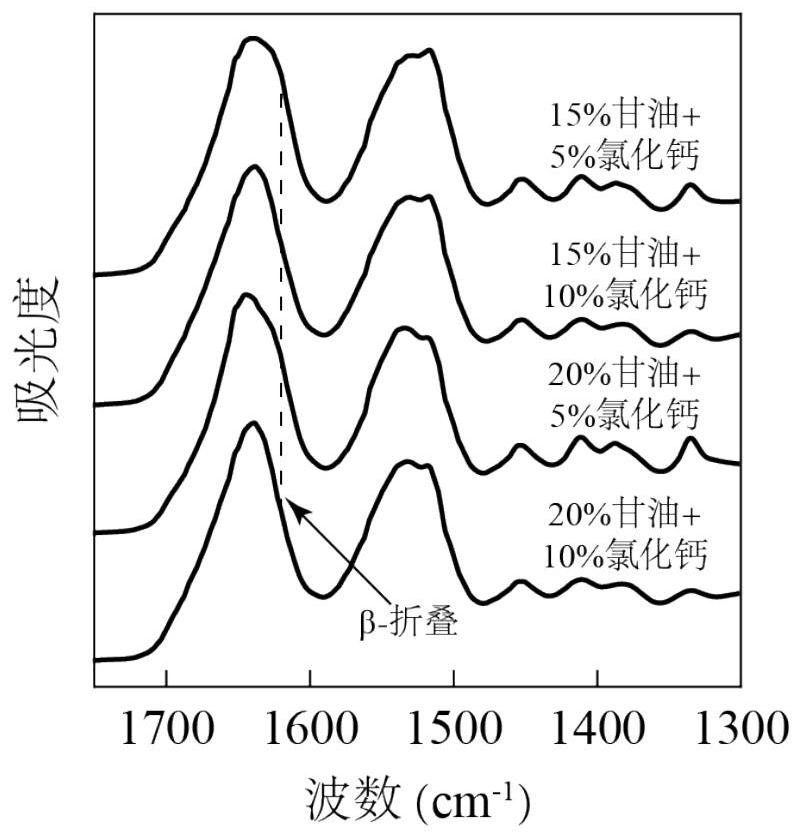

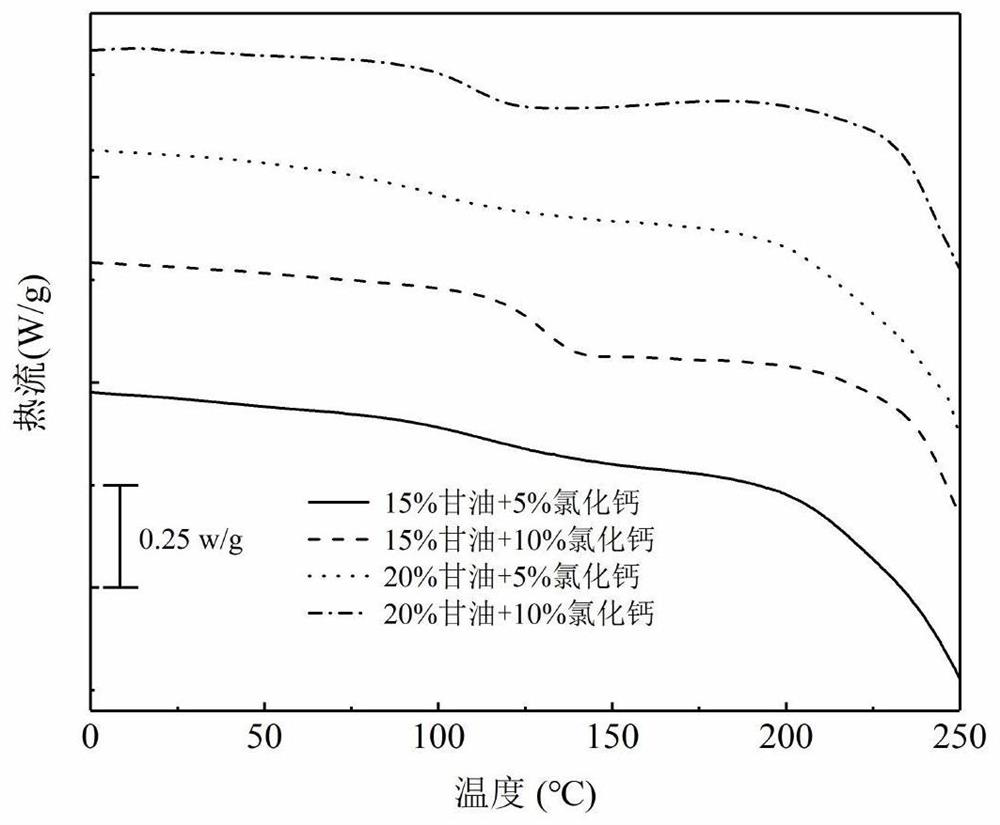

[0080] Analysis of results: from figure 2 and image 3 From the data in , it can be seen that with the increase of the proportion of added glycerol, the β-sheet content in the degradable super tenacious silk protein film also increases, and the glass transition temperature of silk protein molecules decreases.

[0081] From Figure 4 It can be seen from the data in that, as the ratio of glycerin and calcium chloride increases, the elongation at br...

Embodiment 5

[0089] Concentrate the low-concentration silk protein / glycerin / calcium chloride mixed aqueous solution prepared in Example 3 to prepare a high-concentration mixed silk protein aqueous solution. After the concentrated silk protein aqueous solution is centrifuged and purified, it can be stored stably at low temperature, and the concentration is 40%. Figure 7 It is a picture of high-concentration silk protein / glycerin / calcium chloride concentrate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com