A chitosan-based pure physical cross-linked double network hydrogel and preparation method thereof

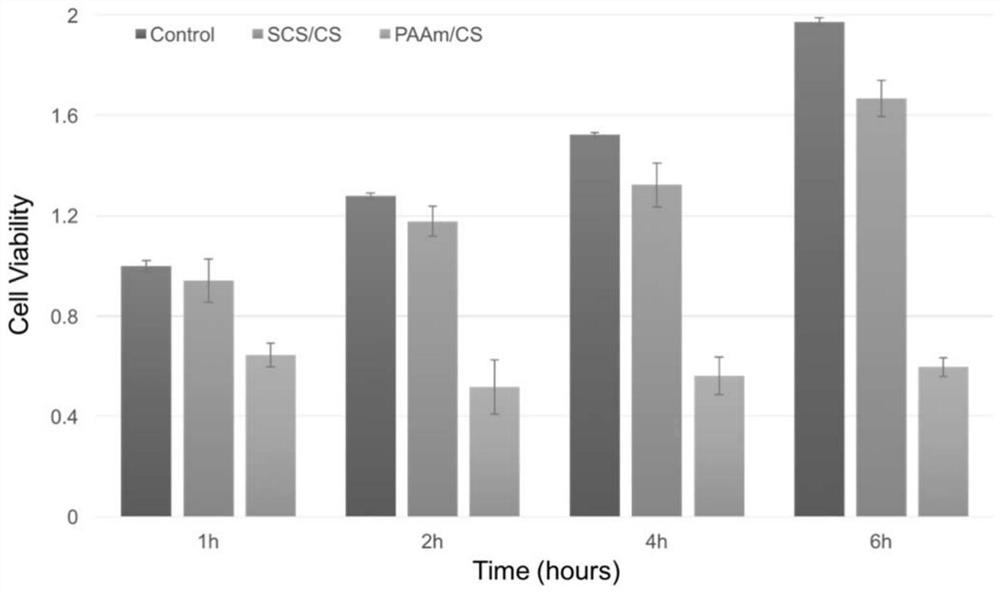

A technology of hydrogel and chitosan, which is applied in the field of chitosan-based pure physical cross-linked double network hydrogel and its preparation, can solve the problems of weak physical cross-linking, achieve enhanced mechanical properties, and excellent biocompatibility properties, the effect of accelerating the gelation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

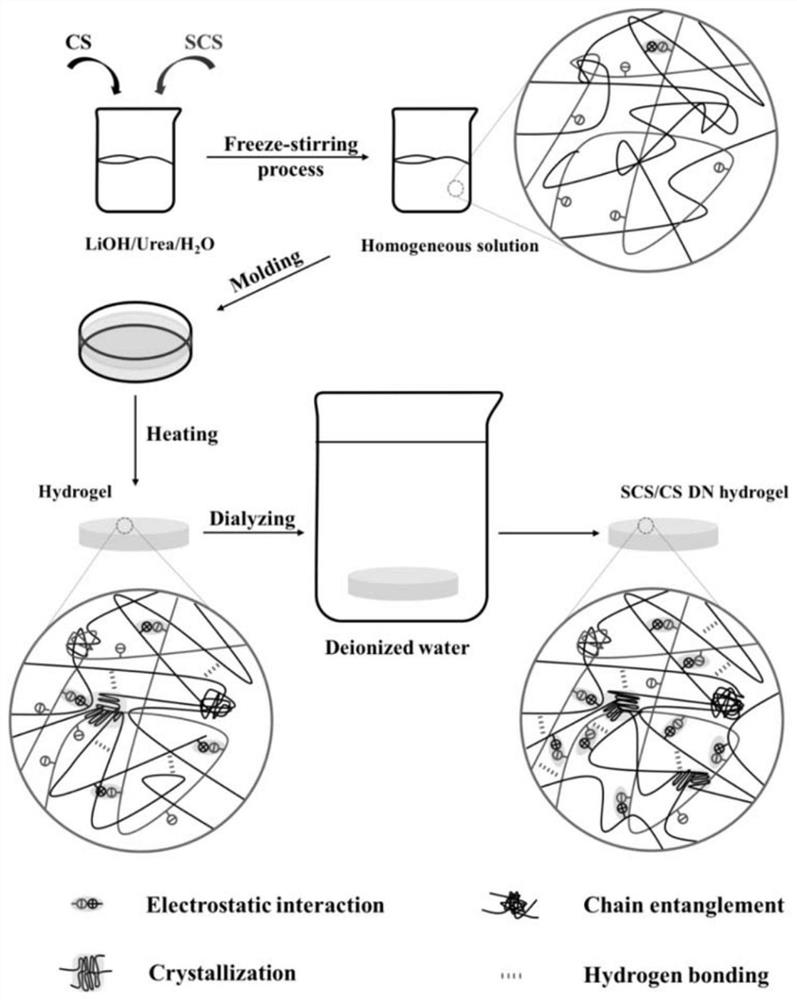

[0029] 1) First weigh a certain amount of lithium hydroxide monohydrate and urea and dissolve them in deionized water to form a clear solution, wherein the weight fractions of lithium hydroxide and urea are 3% and 6% respectively, and use this solution as the sample for subsequent experiments Alkaline solvent system;

[0030] 2) take by weighing 1 gram of succinylated chitosan (molecular weight 100000, succinylation degree 85%) powder and join in the alkaline solvent prepared in step 1), stir for 30 minutes, then weigh 6 gram of chitosan ( Molecular weight 2,000,000, degree of deacetylation 95%) was added in the above-mentioned solution, stirred again for 30 minutes, and was mixed with a 3% solution of succinylated chitosan / chitosan mass fraction;

[0031] 3) The mixture prepared in step 2) was repeatedly frozen (-80°C)-thawed (30°C), and kept stirring during the thawing process. After freezing-thawing was repeated 3 times, a more transparent succinylated Chitosan / chitosan al...

Embodiment 2

[0037] 1) First, a certain amount of lithium hydroxide monohydrate and urea were weighed and dissolved in deionized water to form a clear solution, wherein the weight fractions of lithium hydroxide and urea were 9% and 12% respectively, and this solution was used as a sample for subsequent experiments. Alkaline solvent system;

[0038] 2) take by weighing 1 gram of succinylated chitosan (molecular weight 20000, degree of succinylation 90%) powder and join in the alkaline solvent prepared in step 1), stir for 60 minutes, then weigh 5 gram of chitosan ( Molecular weight 5000000, degree of deacetylation 80%) is added in the above-mentioned solution, stirs again 10 minutes, is mixed with the solution that succinylated chitosan / chitosan mass fraction is 2%;

[0039] 3) The mixture prepared in step 2) was repeatedly frozen (-60°C)-thawed (20°C), and kept stirring during the thawing process. After freezing-thawing was repeated 5 times, a more transparent succinylated Chitosan / chitos...

Embodiment 3

[0045] 1) First weigh a certain amount of lithium hydroxide monohydrate and urea and dissolve them in deionized water to form a clear solution, wherein the weight fractions of lithium hydroxide and urea are 6.3% and 9.5% respectively, and use this solution as the sample for subsequent experiments. Alkaline solvent system;

[0046] 2) take by weighing 1 gram of succinylated chitosan (molecular weight 500000, degree of succinylation 80%) powder and join in the alkaline solvent prepared in step 1), stir for 40 minutes, then weigh 4 gram of chitosan ( Molecular weight 200000, degree of deacetylation 95%) is added in the above-mentioned solution, stirs again 20 minutes, is mixed with the solution that succinylated chitosan / chitosan mass fraction is 5%;

[0047] 3) The mixture prepared in step 2) was repeatedly frozen (-70°C)-thawed (25°C), and kept stirring during the thawing process. After freezing-thawing was repeated 4 times, a more transparent succinylated Chitosan / chitosan al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive modulus | aaaaa | aaaaa |

| degree of deacetylation | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com