Self-repairing fast sealing medical adhesive and production method thereof

A self-healing and fast technology, applied in pharmaceutical formulations, applications, pharmaceutical sciences, etc., can solve problems such as limitations, and achieve the effects of fast gel formation, high gel breaking strength, and reduced blood effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

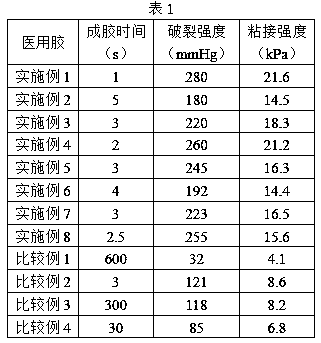

Examples

Embodiment 1

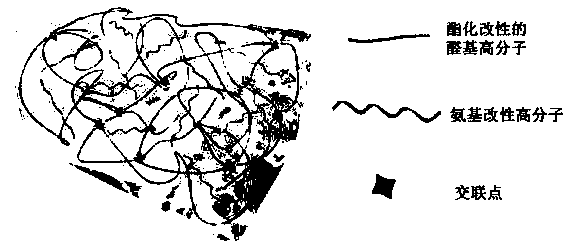

[0036] Dissolve 1 g of aminated gelatin with a molecular weight of 15-25 KDa and an amino molar ratio of 80% in 10 ml of a phosphate buffer solution with a pH value of 7.4, and mechanically stir to dissolve into a uniform solution to obtain solution A.

[0037] Dissolve 1.25g of esterified modified aldehyde sodium alginate with a molecular weight of 80-120KDa, an aldehyde molar ratio of 80%, and a succinimide glutarate group (SG) molar ratio of 80% in 10ml, pH In the phosphate buffer solution with a value of 7.4, dissolve it into a uniform solution with mechanical stirring to obtain solution B.

[0038] The solution A and the solution B are poured into two syringes in the double syringe respectively, and the medical glue is formed through the mixing and atomization of the double syringe.

Embodiment 2

[0040] Dissolve 0.2 g of aminated hyaluronic acid with a molecular weight of 2500-3000 KDa and an amino molar ratio of 40% in 10 ml of a borate buffer solution with a pH value of 10, and mechanically stir to form a uniform solution to obtain solution A.

[0041] Dissolve 0.2g of esterified modified aldehyde-based chitosan with 2000-3000KDa, aldehyde group molar ratio of 40%, succinimide sebacate group (-SSeb) molar ratio of 40% in 10ml, pH 4 in the phosphoric acid solution, dissolved into a homogeneous solution with mechanical stirring to obtain solution B.

[0042]The solution A and the solution B are poured into two syringes in the double syringe respectively, and the medical glue is formed through the mixing and atomization of the double syringe.

Embodiment 3

[0044] Dissolve 2 g of aminated polylysine with a molecular weight of 3-10 KDa and an amino molar ratio of 60% in 10 ml of carbonate buffer solution with a pH value of 8.5, mechanically stir and dissolve to form a uniform solution to obtain solution A.

[0045] Dissolve 2 g of esterified modified aldehyde dextran with a molecular weight of 3-5 KDa, a molar ratio of aldehyde groups of 60%, and a molar ratio of succinimide succinate groups (-SS) of 60% in 10ml, pH 5.5 in acetic acid solution, mechanically stirred and dissolved into a homogeneous solution to obtain solution B.

[0046] The solution A and the solution B are poured into two syringes in the double syringe respectively, and the medical glue is formed through the mixing and atomization of the double syringe.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com