Multifunctional bone filling material containing black phosphorus nanosheets and preparation method thereof

A filling material and nanosheet technology, applied in the fields of biomedicine and polymer materials, can solve the problems of lack of promotion of bone regeneration and poor osteoinductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

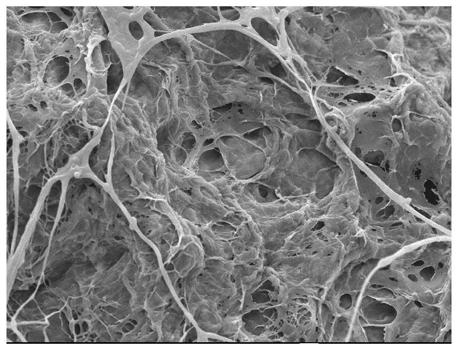

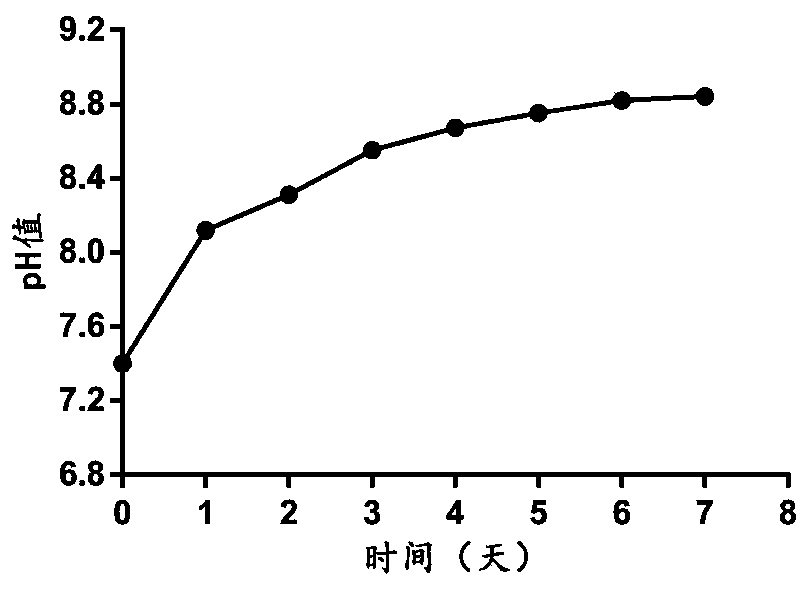

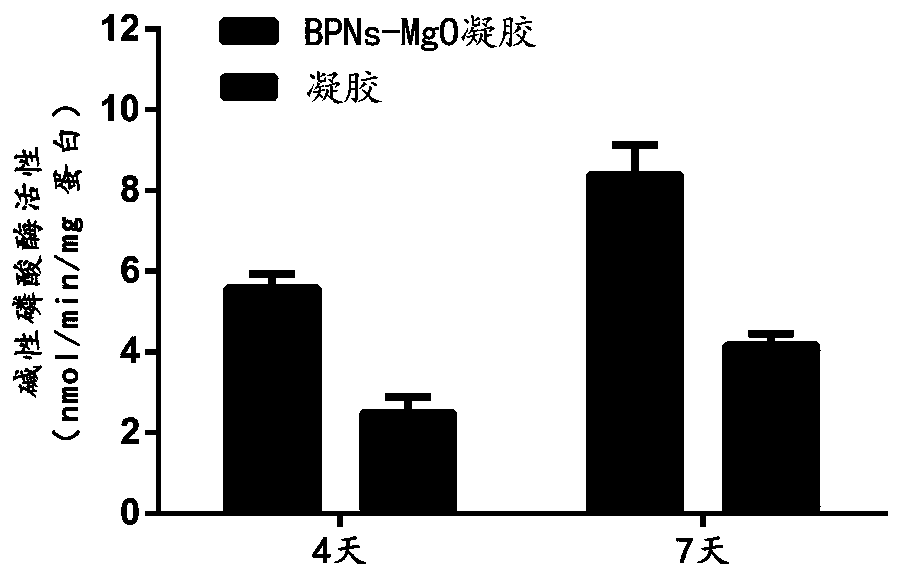

Image

Examples

Embodiment 1

[0047] A method for preparing a multifunctional bone filling material containing black phosphorus nanosheets, comprising the following steps:

[0048] 1. Preparation of black phosphorus nanosheet solution

[0049] (1) According to the ratio of black phosphorus chip to N-methylpyrrolidone 1mg: 1mL, weigh 50mg of black phosphorus (BP) crystals and dissolve them in 50mL of organic solvent N-methylpyrrolidone (NMP), and sonicate for 8h under ice bath conditions, Ultrasonic power: 400W, to obtain the mixed solution 1; centrifuge the mixed solution 1 at 3000rpm for 20min, discard the precipitate, and take the supernatant;

[0050] (2) After centrifuging the supernatant in step (1) at 10000 rpm for 20 min, take the precipitate, resuspend the precipitate with deionized water, centrifuge again at 10000 rpm for 20 min, and repeat the resuspension centrifugation 1-2 times;

[0051] (3) The precipitate obtained in step (2) was resuspended in deionized water to prepare a 1 mg / mL black pho...

Embodiment 2

[0061] 1. Preparation of black phosphorus nanosheet solution

[0062] (1) According to the ratio of black phosphorus chip to N-methylpyrrolidone 1mg: 1mL, weigh 50mg of black phosphorus (BP) crystals and dissolve them in 50mL of organic solvent N-methylpyrrolidone (NMP), and sonicate for 8h under ice bath conditions, Ultrasonic power: 400W, to obtain mixed solution 1; centrifuge mixed solution 1 at 3000rpm for 15min, discard the precipitate, and take the supernatant.

[0063] (2) After centrifuging the supernatant in step (1) at 8000rpm for 15min, take the precipitate, resuspend the precipitate with deionized water, centrifuge again at 8000rpm for 15min, and repeat the resuspension centrifugation 1-2 times.

[0064] (3) The precipitate obtained in step (2) was resuspended in deionized water to prepare a 1 mg / mL black phosphorus nanosheet (BPNs) solution.

[0065] 2. Preparation of hydrogel

[0066] (1) Add PVA (10g) to 100mL of deionized water to make the mass fraction 10wt%...

Embodiment 3

[0073] 1. Preparation of black phosphorus nanosheet solution

[0074] (1) According to the ratio of black phosphorus chip to N-methylpyrrolidone 1mg: 1mL, weigh 50mg of black phosphorus (BP) crystals and dissolve them in 50mL organic solvent N-methylpyrrolidone (NMP), and sonicate for 10h under ice bath conditions, Ultrasonic power: 400W, to obtain mixed solution 1; centrifuge mixed solution 1 at 4000rpm for 20min, discard the precipitate, and take the supernatant.

[0075] (2) After centrifuging the supernatant in step (1) at 12000 rpm for 20 min, take the precipitate, resuspend the precipitate with deionized water, centrifuge again at 12000 rpm for 20 min, and repeat the resuspension centrifugation 1-2 times.

[0076] (3) The precipitate obtained in step (2) was resuspended in deionized water to prepare a 1 mg / mL black phosphorus nanosheet (BPNs) solution.

[0077] 2. Preparation of hydrogel

[0078] (1) Add PVA (30g) to 100mL deionized water to make the mass fraction 30wt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com