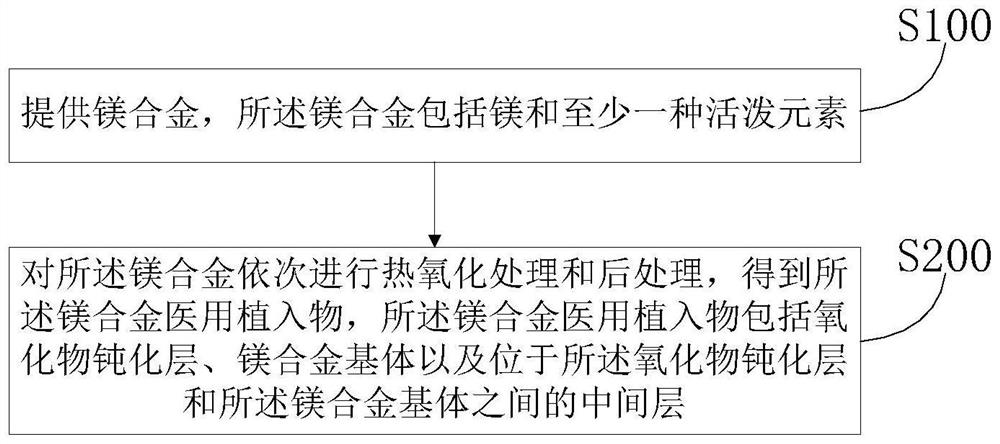

Magnesium alloy medical implant and preparation method thereof

A magnesium alloy and implant technology, which is applied in the field of biodegradable magnesium alloy medical implants and its preparation, can solve the problems of inappropriate degradation rate of magnesium alloy medical implants, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

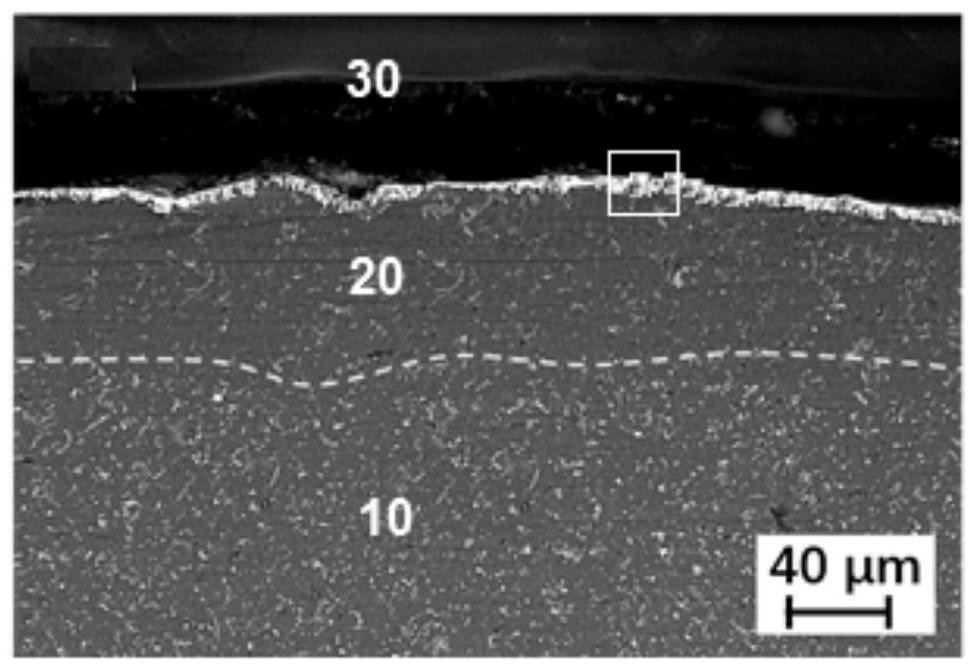

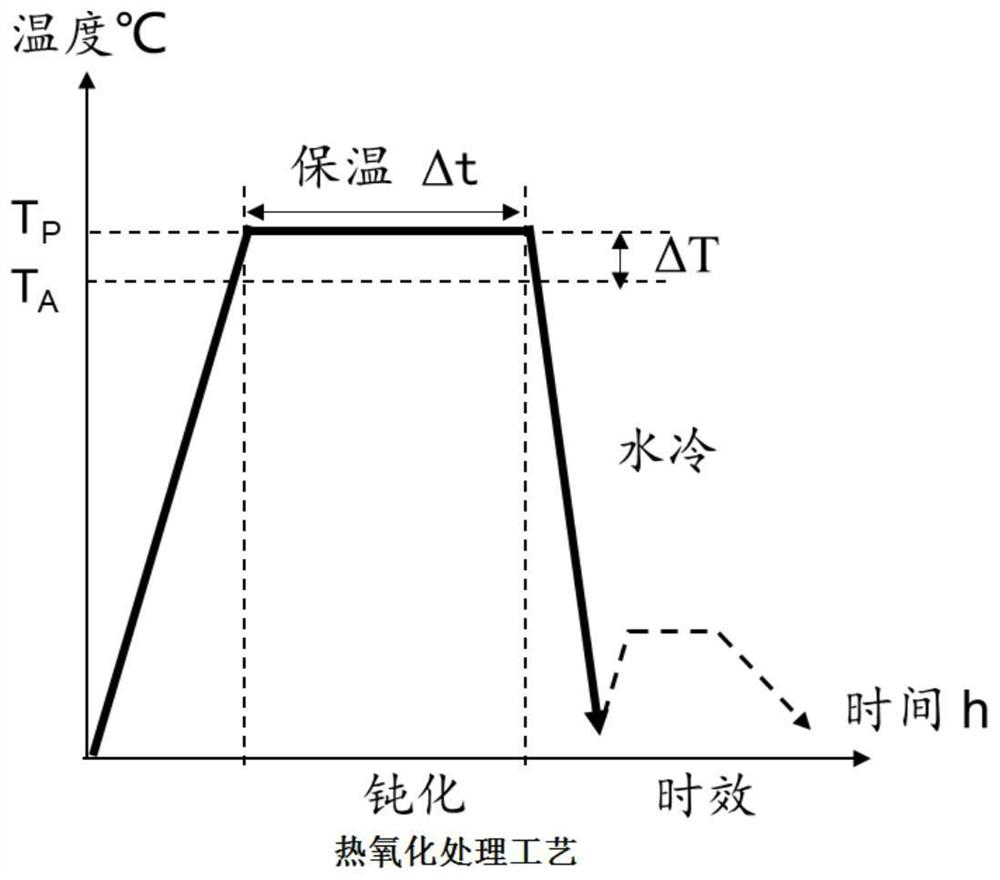

Method used

Image

Examples

Embodiment 1

[0078] The additive manufacturing equipment used in this example is the S-210 laser powder bed melting equipment produced by Xi’an BLT Additive Technology Co., Ltd. The magnesium alloy powder used in this example is produced by Tangshan Weihao Magnesium Powder Co., Ltd. WE43 magnesium alloy powder with a particle size range of 20-63 μm and a median diameter of 41 μm.

[0079] Before printing, draw a rectangular block with a length, width, and height of 5*2*5mm, and then use the subdivision software that comes with the laser powder bed melting printer to subdivide. After the subdivision is completed, import the layered file to the printer for preparation Print. Argon gas was used for protection during the printing process, the oxygen content in the printing chamber was controlled at 800ppm, and the temperature of the heating plate was adjusted to 200°C. The laser power used for printing is 80W, the scanning speed is 800mm / s, and the spot diameter is 70μm. The scanning track p...

Embodiment 2

[0085] In order to verify that the thermal oxidation treatment method is also effective for porous magnesium alloy implants, this example uses 3D printing to prepare a WE43 magnesium alloy porous scaffold and conduct passivation treatment, and at the same time verify its degradation behavior and mechanical properties.

[0086] The powder laser melting 3D printing equipment and WE43 magnesium alloy powder used in this embodiment are the same as those in Embodiment 1. Using 3D computer modeling software, draw a Gyroid structure porous scaffold with a diameter of 6 mm, a height of 6 mm, a porosity of 40%, and a rod diameter of 600 μm. Use the subdivision software that comes with the 3D printing device to subdivide. After the subdivision is completed, import the layered files to the printer for printing. Argon gas was used for protection during the printing process, the oxygen content in the printing chamber was controlled at 800ppm, and the temperature of the heating plate was ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Median diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com