Gradient composite bar material and manufacturing method thereof

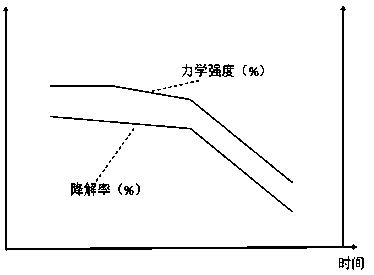

A manufacturing method and composite rod technology, applied in the field of medical devices, can solve the problems of causing chronic inflammation, rejection reaction, and difficulty in recovery, and achieve the effects of slowing down the degradation speed, slowing down the debilitating speed, and facilitating bone conduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

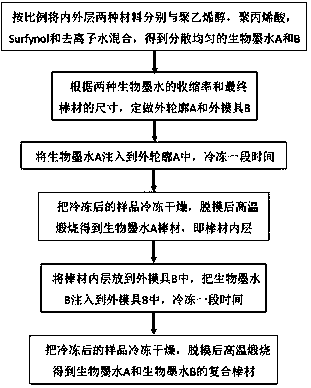

Method used

Image

Examples

Embodiment 1

[0053] 1) Evenly mix 55% calcium magnesium silicate powder with 2.1% polyvinyl alcohol, 0.5% polyacrylic acid, 0.5% Surfynol and 41.9% deionized water to obtain bioink A, and then Bioink B was obtained by uniformly mixing 50% hydroxyapatite with 2.2% polyvinyl alcohol, 0.5% polyacrylic acid, 0.5% Surfynol and 46.8% deionized water.

[0054] 2) According to the shrinkage rate of bio-inks A and B, the outer contour A of the quartz tube with an inner diameter of 6.8mm and a wall thickness of 1.6mm is customized, a shell with an inner diameter of 6.1mm and a wall thickness of 1mm, and a matching center seat.

[0055] 3) Stand up the outer contour A, and then slowly inject the bio-ink A prepared in step 1) into the outer contour A from bottom to top. After filling, put the bio-ink A and the outer contour A together at minus 70 o C for 3 hours in the freezer.

[0056] 4) Freeze-dry the above-mentioned frozen samples with a freeze dryer to separate the rough rod of bio-ink A and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com