Controllablely degradable internal fixation composite material and preparation method and application thereof

A technology of composite materials and composite powders, which is applied in the fields of internal bone synthesis, fixers, medical science, etc., can solve the problems of affecting the mechanical properties of composite materials, the neutralization effect needs to be improved, and the burden and pain of patients will be increased, so as to achieve a good industrialization prospect , promote bone healing, improve biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

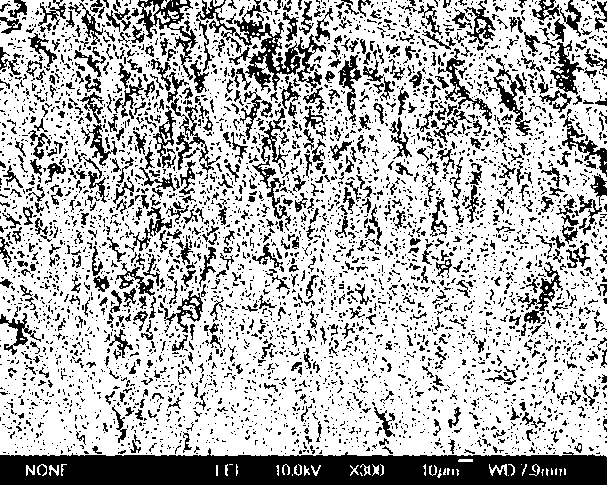

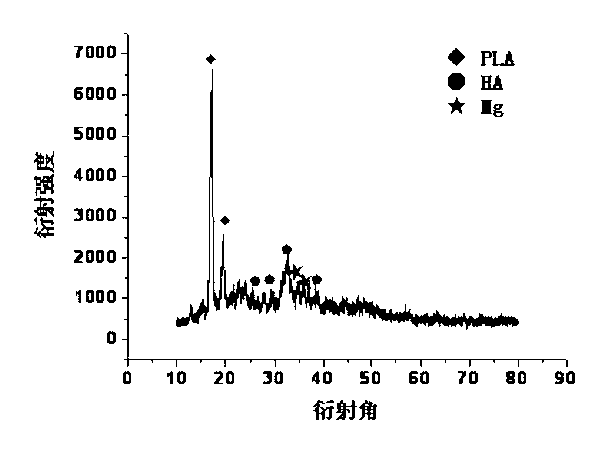

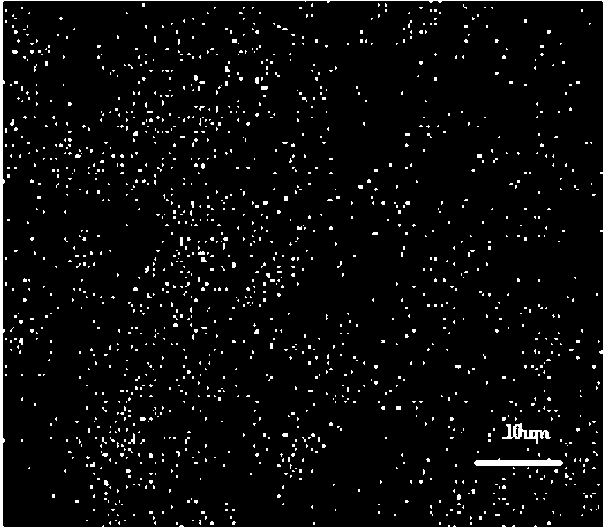

[0032] Prepare 500 g of Mg-HA / PLA composite material with magnesium content of 3%, HA content of 10%, and polylactic acid as the rest, and shape it into a bone screw. The steps are as follows:

[0033] 1) First, calcium nitrate (Ca(NO 3 ) 2 4H 2 O) and ammonium phosphate (NH4) 3 PO 4 ·3H 2 O is the raw material, weighed according to Ca / P=1.67 (stoichiometric ratio), and made 100 ml aqueous solution with deionized water respectively. Ca(NO 3 ) 2 The solution was all moved into a three-necked flask, and then 100 milliliters of 0.1 g / ml gelatin aqueous solution was added, the mixed solution was heated to 80° C., the reaction pH was adjusted to 9 with NaOH solution, and the (NH 4 ) 3 PO 4 solution while stirring vigorously. The reaction temperature and the pH value of the reaction system were kept constant throughout the experiment. After the dropwise addition, 100 ml of 0.1 g / ml polyethylene glycol was added and stirred at constant temperature for 30 min. Raise the te...

Embodiment 2

[0038] Prepare 500g of Mg-HA / PLA composite material with magnesium content of 2%, HA content of 8%, and polylactic acid as the rest, and shape it into a bone nail. The steps are as follows:

[0039] 1) First, calcium nitrate (Ca(NO 3 ) 2 4H 2 O) and ammonium phosphate (NH4) 3 PO 4 ·3H 2 O is the raw material, weighed according to Ca / P=1.67 (stoichiometric ratio), and made 100 ml aqueous solution with deionized water respectively. Ca(NO 3 ) 2 Move all the solution into a three-necked flask, add 100 milliliters of 0.1 g / ml gelatin aqueous solution, heat the mixed solution to 90 ° C, adjust the reaction pH value to 10 with ammonia water, and start to drop (NH 4 ) 3 PO 4 solution while stirring vigorously. The reaction temperature and the pH value of the reaction system were kept constant throughout the experiment. After the dropwise addition, 100 ml of 0.1 g / ml polyethylene glycol was added and stirred at constant temperature for 60 min. Raise the temperature of the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com