Paint for medical instrument, and preparation method and application thereof

A medical device and coating technology, which is applied in the field of medical device coating and its preparation, can solve the problems of infection risk and poor osteogenesis, and achieve the effects of wide application range, improved antibacterial property, and strong controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

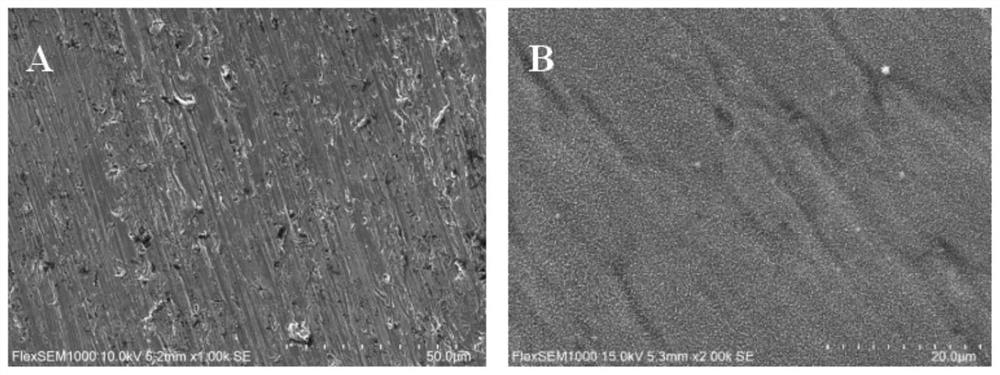

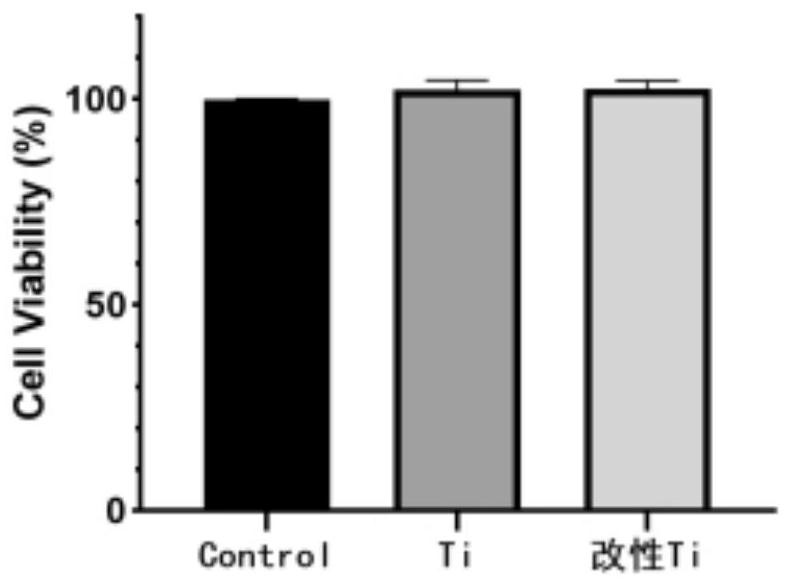

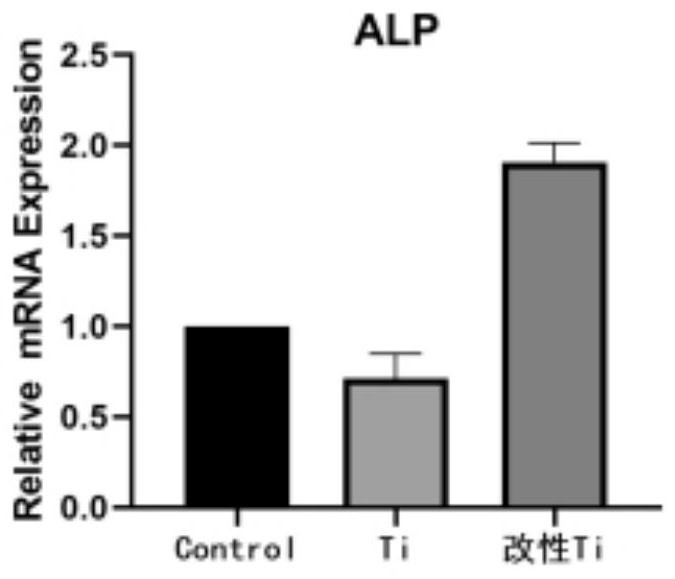

Image

Examples

Embodiment 1

[0065] A coated titanium substrate comprises a 1×1×2 cm titanium substrate and a coating formed by paint on the surface of the titanium substrate. The raw material components for preparing this coating include: 40mg epigallocatechin gallate, 20mg zinc acetate, 41mg strontium chloride, 20mg ammonium persulfate, 40mL phosphate buffered saline solution (i.e. PBS buffer, pH value is 8.0) .

[0066] The preparation method of the above-mentioned coated titanium substrate comprises the following steps:

[0067] (1) Place the titanium base material in acetone, ethanol, and deionized water for ultrasonic cleaning for 15 minutes in order to obtain the cleaned titanium base material;

[0068] (2) Soak the cleaned titanium substrate in a sodium hydroxide solution (molar concentration: 4mol / L) at 60°C for 8 hours to obtain the soaked titanium substrate;

[0069] (3) Place the soaked titanium substrate in deionized water for ultrasonic cleaning for 20 minutes, and dry to obtain the pretre...

Embodiment 2

[0073] A coated polyetheretherketone comprises polyetheretherketone and a coating formed by paint on the surface of the polyetheretherketone. The polyether ether ketone is a cylinder with a diameter of 1 cm and a height of 3 cm.

[0074] The raw material components for preparing the coating include: 20mg epigallocatechin gallate, 30mg zinc acetate, 30mg strontium chloride, 30mg ammonium persulfate, 40mL tris hydrochloride solution (i.e. Tris-HCl buffer, pH 7.5).

[0075] The preparation method of the polyether ether ketone covered by the above coating comprises the following steps:

[0076] (1) Put the polyetheretherketone in acetone, ethanol, and deionized water for 10 minutes to ultrasonically clean it respectively to obtain the cleaned polyetheretherketone;

[0077] (2) Soak the cleaned polyetheretherketone in a sodium hydroxide solution (molar concentration: 3mol / L) at 60°C for 5 hours to obtain the soaked polyetheretherketone;

[0078] (3) Place the soaked polyether et...

Embodiment 3

[0082] A coated medical ceramic sheet comprises a medical ceramic sheet of 1 x 1 x 3 cm and a coating formed of paint on the surface of the medical ceramic sheet.

[0083] The raw material components for preparing the coating include: 40mg epigallocatechin gallate, 30mg zinc acetate, 30mg strontium chloride, 40mg ammonium persulfate, 40mL tris hydrochloride solution (i.e. Tris-HCl buffer, pH 7.5).

[0084] The preparation method of the above-mentioned coated medical ceramic sheet comprises the following steps:

[0085] (1) Place the medical ceramic sheet in acetone, ethanol, and deionized water for 10 minutes for ultrasonic cleaning respectively to obtain the cleaned medical ceramic sheet;

[0086] (2) Soak the cleaned medical ceramic sheet in a sodium hydroxide solution (molar concentration: 3mol / L) at 70°C for 6 hours to obtain the soaked medical ceramic sheet;

[0087] (3) Ultrasonic cleaning of the soaked medical ceramic sheet in deionized water for 10 minutes, and dryin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com