A kind of biological glass fiber-modified polyester composite dressing and preparation method thereof

A glass fiber, modified polyester technology, applied in glass manufacturing equipment, manufacturing tools, bandages, etc., can solve problems such as unsuitable use, dipping of surrounding skin, slowness, etc., to improve uniformity and strength, and good biocompatibility , the effect of good biological activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] (1) Preparation of borate glass fiber:

[0067] Prepare the molar ratio of each composition as Na 2 O:K 2 O:MgO:CaO:B 2 o 3 :SiO2 2 :P 2 o 5 :SrO=6:8:8:22:18X:(54-18X):2:6 borate glass fiber, X=1, weigh the ingredients according to Table 1 and mix them evenly, add them into the crucible and heat to melt, The melting temperature is 1400°C, and the melting homogenization time is 2 hours. In the molten state, after the molten glass flows out, use air at 25°C and an air pressure of 2.0MPa to spray the molten glass vertically to naturally cool the biological glass fiber in cotton state with a diameter of 50nm-50μm and a length of 1mm-10cm.

[0068] Table 1

[0069] components mass (g) Na 2 CO 3

4.323 K 2 CO 3

11.275 MgCO 3 ~3Mg(OH) 3 ~5H 2 o

7.924 CaCO 3

16.330 SrCO 3

9.032 h 3 BO 3

23.378 SiO 2

22.055 NaH 2 PO 4 ~2H 2 o

6.363

[0070] (2) Disperse the borat...

Embodiment 2

[0086] (1) Preparation of borate glass fiber:

[0087] Prepare the molar ratio of each composition as

[0088] Na 2 O:K 2 O:MgO:CaO:B 2 o 3 :SiO2 2 :P 2 o 5 :SrO:Ag 2 O=6:8:8:22:18X:(54-18X):2:6:1 borate glass fiber, X=2, Ag 2The doping amount of O accounts for 1wt% of the total mass. The ingredients are weighed according to Table 2 and mixed evenly. After adding to the crucible, heat and melt. The melting temperature is 1250 ° C, and the melting and homogenization time is 2 hours. In the molten state, after the molten glass flows out, use air at 25°C and an air pressure of 2.0MPa to spray the molten glass vertically to naturally cool the biological glass fiber in cotton state with a diameter of 50nm-50μm and a length of 1mm-10cm.

[0089] Table 2

[0090] components mass (g) Na 2 CO 3

3.871 K 2 CO 3

10.096 MgCO 3 ~3Mg(OH) 3 ~5H 2 o

7.096 CaCO 3

14.624 SrCO 3

8.088 h 3 BO 3

41.871 S...

Embodiment 3

[0108] (1) Preparation of borate glass fiber:

[0109] Prepare the molar ratio of each composition as Na 2 O:K 2 O:MgO:CaO:B 2 o 3 :SiO2 2 :P 2 o 5 :SrO=6:8:8:22:18X:(54-18X):2:6 borate glass fiber, X=1, weigh the ingredients according to Table 1 and mix them evenly, add them into the crucible and heat to melt, The melting temperature is 1400°C, and the melting homogenization time is 2 hours. In the molten state, after the molten glass flows out, use air at 25°C and an air pressure of 2.0MPa to spray the molten glass vertically to naturally cool the biological glass fiber in cotton state with a diameter of 50nm-50μm and a length of 1mm-10cm.

[0110] table 3

[0111]

[0112]

[0113] (2) Disperse the borate biological glass fiber:

[0114] (2-1) Preparation of dispersant:

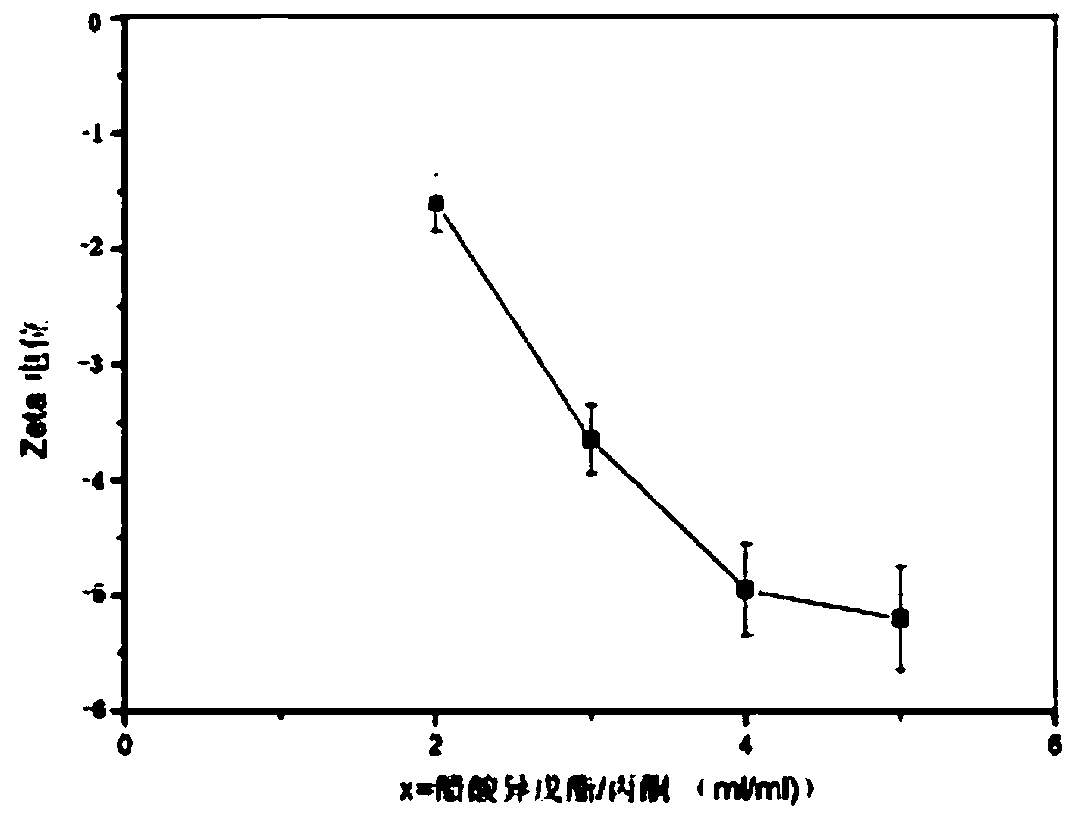

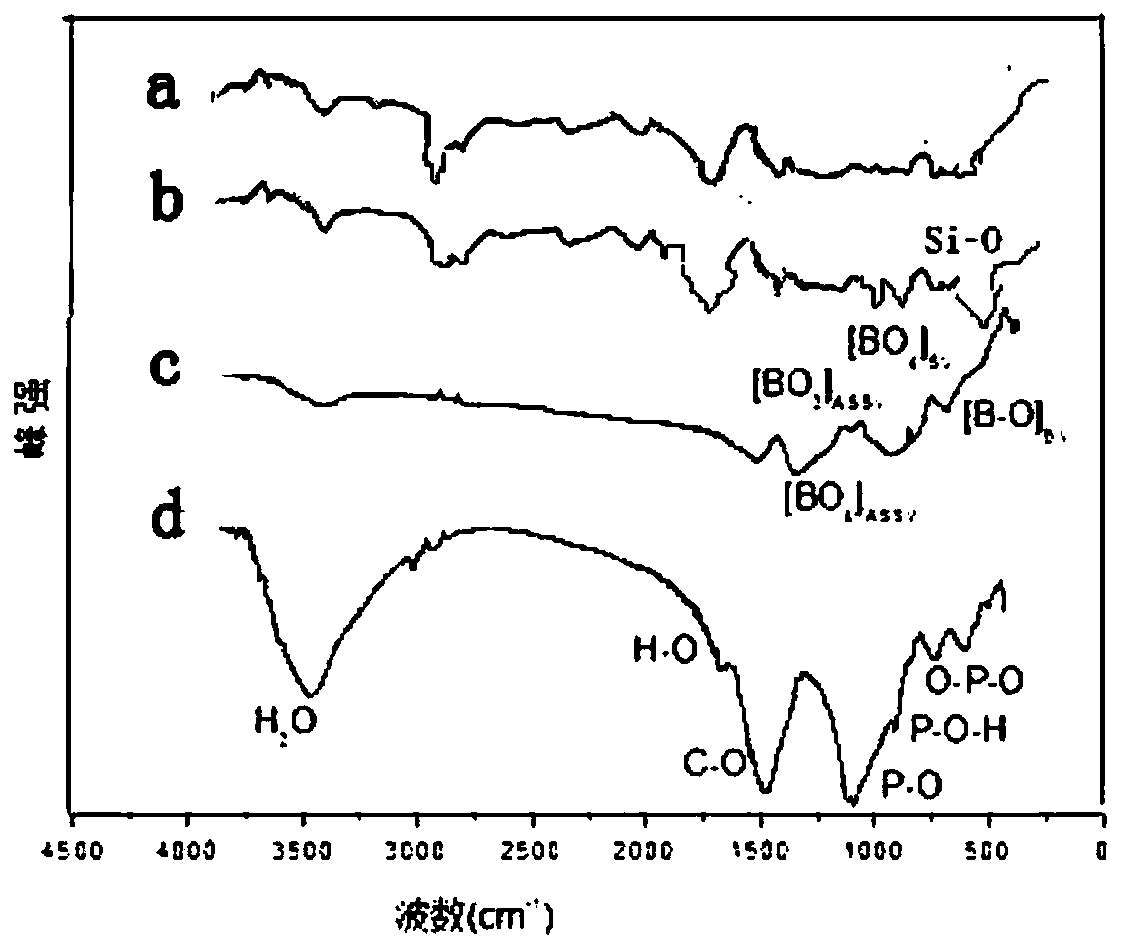

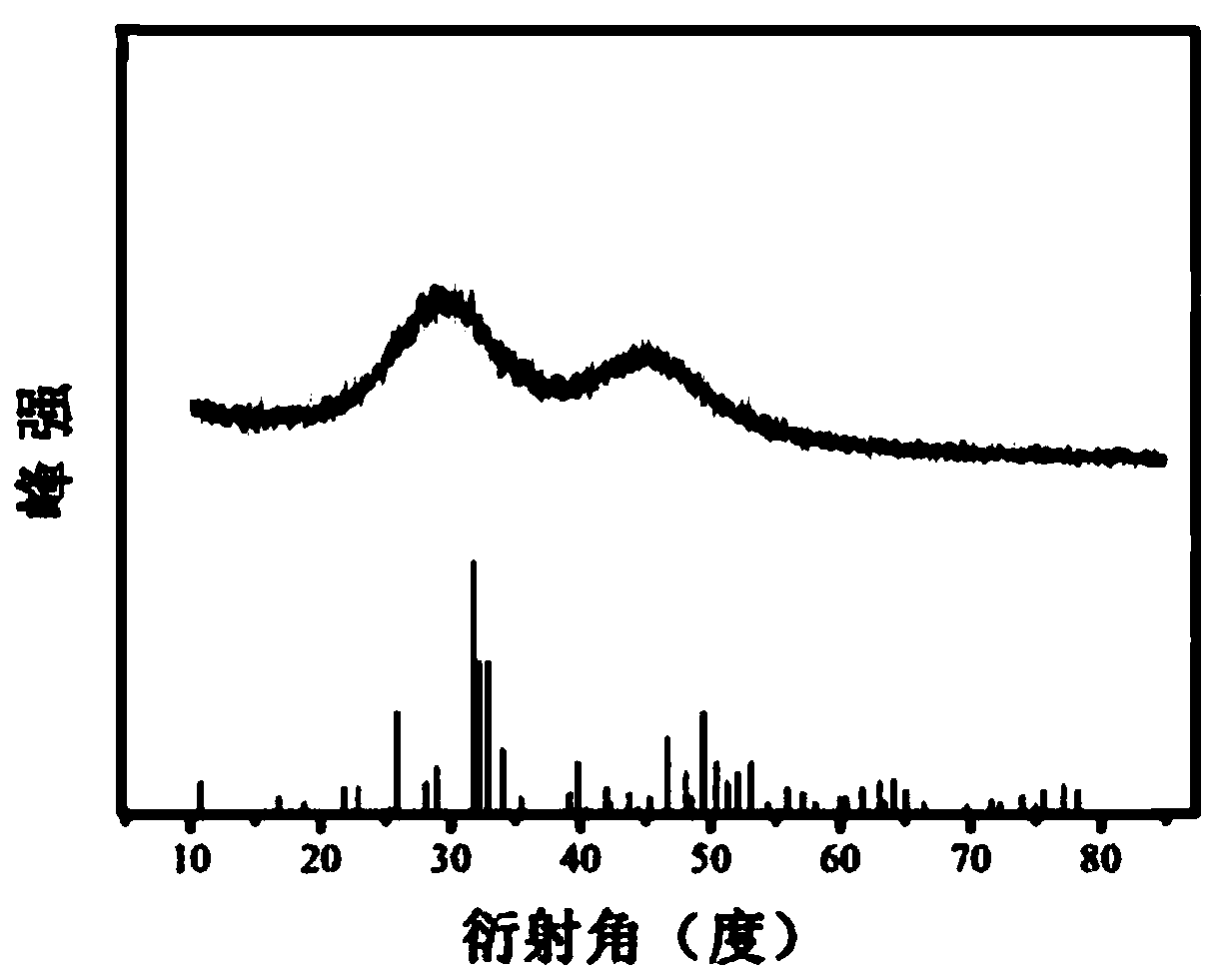

[0115] Select the dispersant component (isoamyl acetate CH) that makes the surface potential value of the borate biological glass fiber minimum (i.e. the minimum absolute value) in the pres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com