New process for preparing microcrystalline cellulose from lignocelluloses biomass

A lignocellulosic and microcrystalline cellulose technology, which is used in fiber raw material processing, textile and papermaking, etc., can solve problems such as low enzymatic hydrolysis efficiency, waste of cellulose, and damage to cellulose structure, and achieve mild processing conditions and peel off. Good effect, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

reference example 1

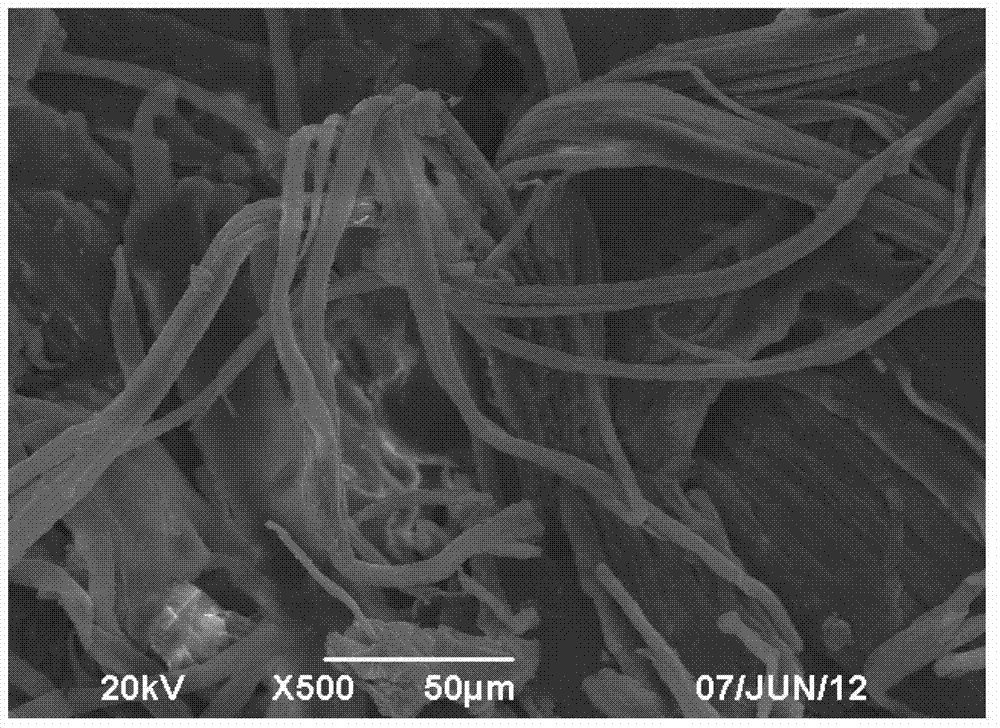

[0032] Reference example 1: Put 80g of corn stalks into 300mL, 3% nitric acid solution, stir for 2h at 90℃, filter and wash twice; then add 300mL, 3% pectinase, stir for 2h at 45℃, and wash; then add 300mL, 3 %NaOH solution, stirring at 90°C for 2h, stirring repeatedly to melt the cellulose for 15min to clean impurities. Then it was added to 300mL, 2% hydrochloric acid and stirred at 90°C for 2h, filtered and cleaned by suction; finally, bleached in 300mL, 15% hydrogen peroxide solution, and left standing at room temperature for 12h, washed, and dried at 60°C to obtain 16g of white Microcrystalline cellulose. The microcrystalline cellulose is white powder in appearance, neutral in pH, and generally below 1 mm in length.

reference example 2

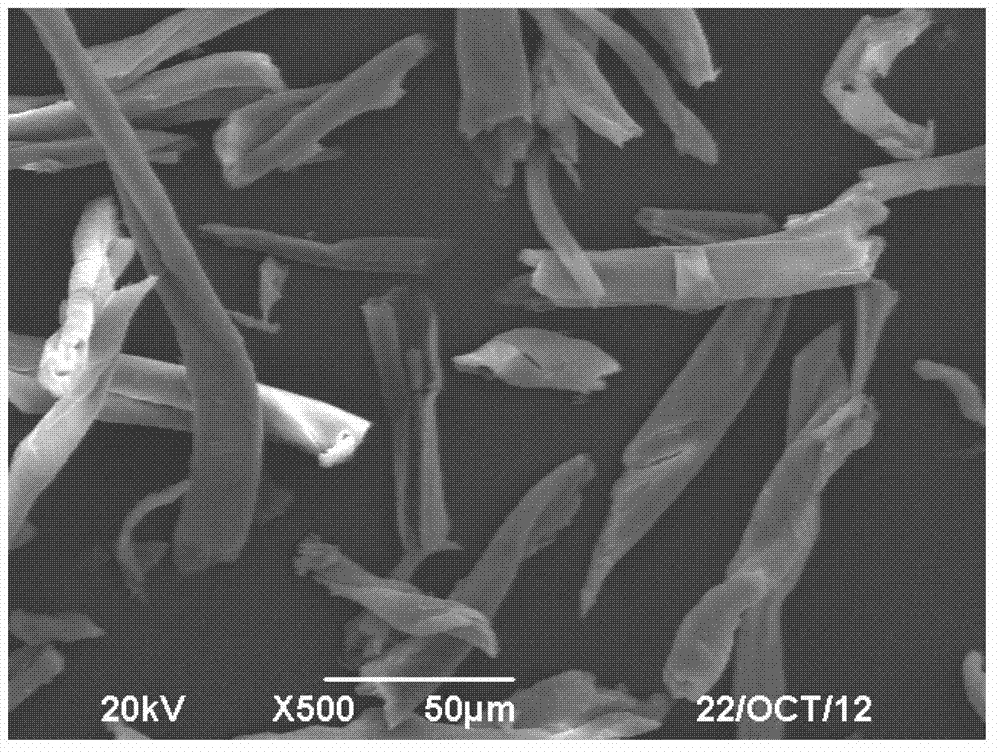

[0033] Reference example 2: Chop the straw to 1-3cm, take 10.0g, treat it with 40mL 20% fuming sulfuric acid at 60℃ for 2h, then use 2% dilute NaOH solution at 95℃ to alkaline wash for 2h, filter and wash until medium To obtain the holocellulose; acidify the above holocellulose with 1M HCl at 90℃ for 2h, filter and wash with water until it is neutral, and finally use 30% H 2 O 2 After bleaching, washing to neutrality, drying and powdering, 3.5 g of straw cellulose is obtained, the cellulose content is 84.8%, the hemicellulose content is 4.6%, the crystallinity is 75.2%, and the burning residue is 0.37%.

reference example 3

[0034] Reference example 3: Weigh 10g of bagasse cellulose pulp, a raw material obtained from bagasse paper pulp, add 1200g of deionized water, soak for 30 minutes, pour it into an autoclave, purge with nitrogen, fill with nitrogen, and react at 200℃ for 180 Minutes, remove the autoclave to cool, open the lid, pour out the mixed liquid, centrifuge, and pour out the upper liquid. The solid obtained is bagasse microcrystalline cellulose with a degree of polymerization of 120. The product can be bleached, washed, centrifuged, and filtered. ,dry.

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com