Method for preparing fish fertilizer from straw

A technology of straw and fish fertilizer, which is applied in the field of plant straw treatment and application, can solve the problems of destroying cellulose structure, easily causing safety problems, and high irritation, so as to achieve safe and reliable operation, enhance fish body immunity, and promote growth Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

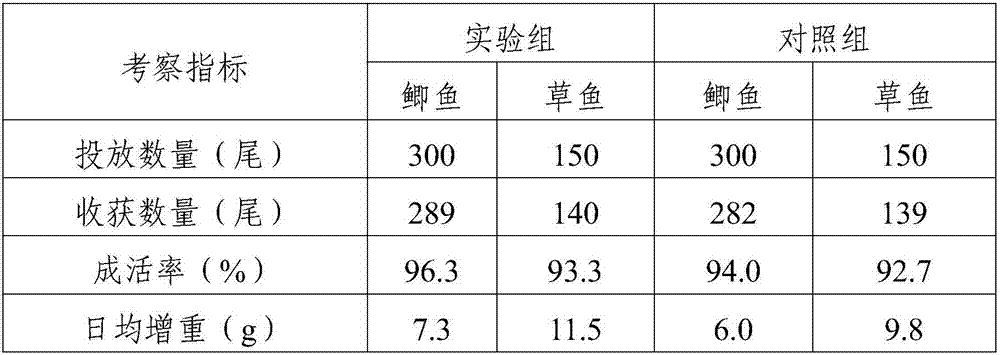

Examples

Embodiment 1

[0024] A method for preparing fish fertilizer from stalks, comprising the following steps:

[0025] (1) Preparation of microcrystalline cellulose: submerge pulverized 100g rice straw in 300ml 0.5mol L -1 100ml of 0.05mol·L -1 ammonium chloride solution, transferred to a microwave reactor to react for 10min, filtered to take the filter cake, passed ammonia gas into the wet filter cake under airtight conditions while it was hot, reacted at 60°C for 1.5h, and then added 300ml of 0.5mol L -1 NaOH solution, continue to react for 6h, filter, wash the filter cake with water until the pH value is 7, add the crude enzyme obtained by the solid-state mixed fermentation of Aspergillus nigerA3 and Trichoderma sp.T6, that is, cellulose and xylan mixed enzyme, After treatment at 60°C for 16 hours, add activated carbon, filter, wash the filter cake with water until the pH value is 7, and dry to obtain 20.0 g of microcrystalline cellulose, a white powder;

[0026] (2) Preparation of reducing...

Embodiment 2

[0031] A method for preparing fish fertilizer from stalks, comprising the following steps:

[0032] (1) Preparation of microcrystalline cellulose: immerse the mixed straw of 50g corn stalks and 50g rice straw in 300ml0.5mol L -1 100ml of 0.05mol·L -1 ammonium chloride solution, transferred to a microwave reactor to react for 10min, filtered to take the filter cake, passed ammonia gas into the wet filter cake under airtight conditions while it was hot, reacted at 60°C for 1.0h, and then added 300ml of 0.5mol·L -1 NaOH solution, continue to react for 6h, filter, wash the filter cake with water until the pH value is 7, add the crude enzyme that is the mixed enzyme of cellulose and xylan produced by solid-state mixed fermentation of Aspergillus niger A3 and Trichoderma sp.T6 , after treatment at 60°C for 16 hours, add activated carbon, filter, wash the filter cake with water until the pH value is 7, and dry to obtain 21.2 g of microcrystalline cellulose, a white powder;

[0033]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com