Compound porous electrode and preparation method thereof as well as flow battery comprising compound porous electrode

A porous electrode and solution technology, used in battery electrodes, indirect fuel cells, circuits, etc., can solve the problem of not being able to improve electrochemical activity and electrical conductivity at the same time, and achieve improved electrochemical activity, mild treatment conditions, and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

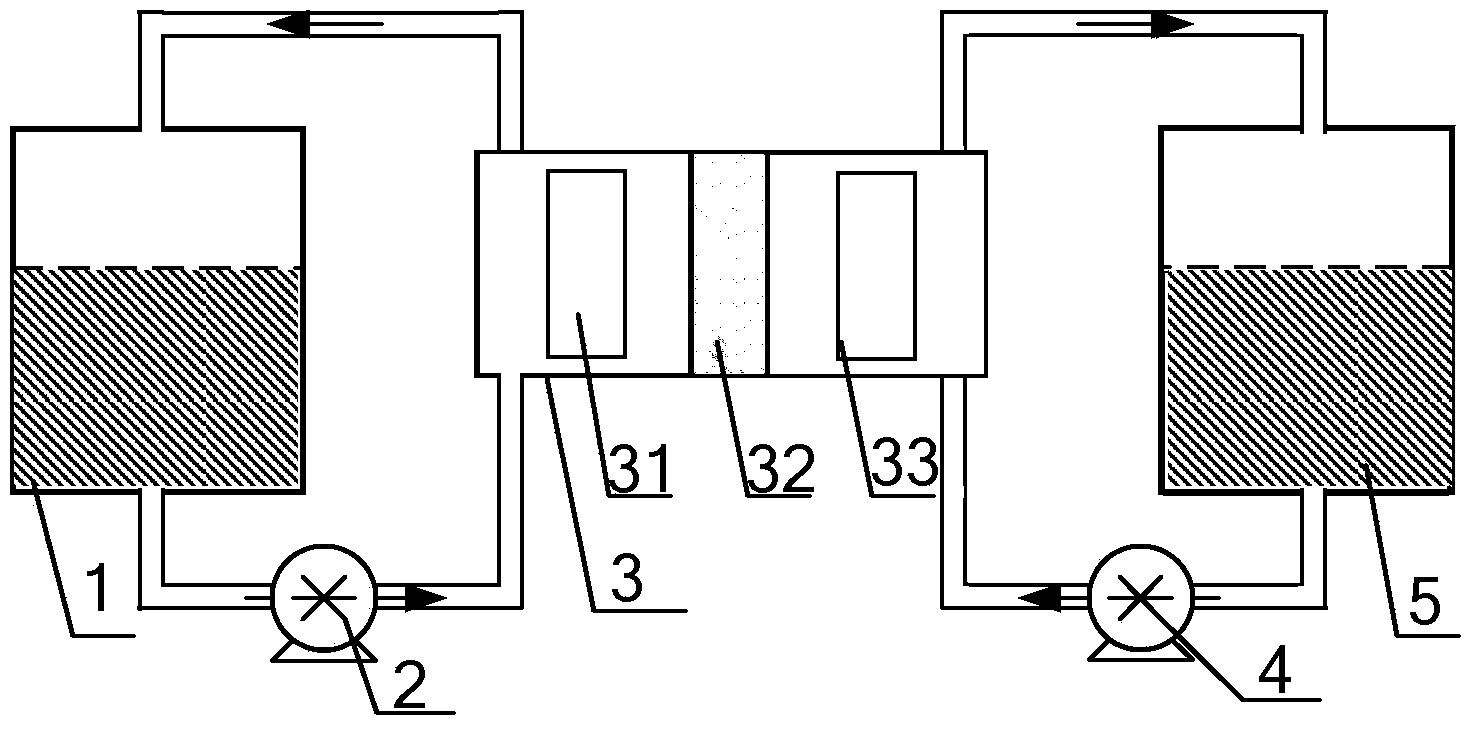

Image

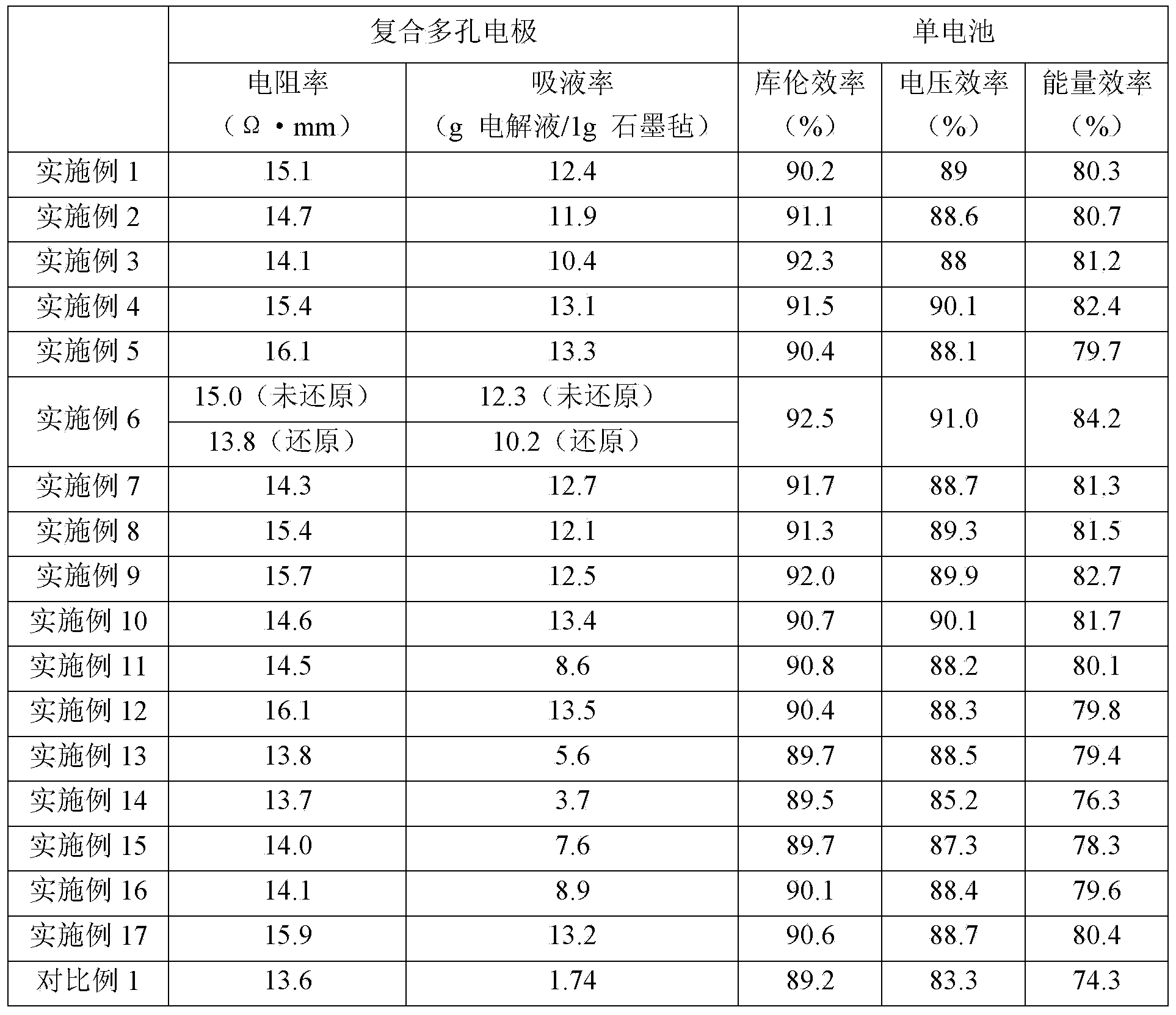

Examples

preparation example Construction

[0029] This application overcomes the general belief in the prior art that the material properties of graphene derivatives and porous electrodes are too different to be firmly attached to the surface of porous electrodes, especially when the battery is running, the electrolyte will flow through at a relatively large flow rate. Porous electrodes are very easy to wash away the catalytic components loosely attached to the surface of the porous electrodes. The invention provides a preparation method of a composite porous electrode, the preparation method comprising: Step S1, dispersing a solution having graphene oxygen-containing derivatives into a porous electrode body to obtain a composite porous electrode prefabricated body; Step S2, removing The solvent of the solution in the composite porous electrode prefabricated body obtains the composite porous electrode.

[0030]When the composite porous electrode formed by compounding graphene oxygen-containing derivatives rich in oxyge...

Embodiment 1

[0052] (1) Put the polyacrylonitrile graphite felt with a thickness of 5mm and a size of 300mm*500mm into deionized water for ultrasonic cleaning for 20 minutes, put it in an oven at 80°C for 12 hours, and place it in a desiccator for later use.

[0053] (2) Add 750 mg of graphene oxide into 750 ml of deionized water, and use ultrasonic treatment with a frequency of 20000 Hz for 30 min to prepare a dispersion liquid with a graphene oxide content of 1 mg / ml.

[0054] (3) Pour 750ml of the prepared dispersion into a square container with a size of 300mm*500mm*50mm, completely immerse the polyacrylonitrile graphite felt in the solution after ultrasonic cleaning, soak for 1 hour, and then put the dispersion and The container of polyacrylonitrile graphite felt was placed in an oven at 120° C., and heated for 24 hours to remove the solvent to prepare a graphene oxide-polyacrylonitrile graphite felt composite porous electrode.

[0055] (4) The porous composite porous electrode was us...

Embodiment 2

[0057] (1) Put the polyacrylonitrile graphite felt with a thickness of 5mm and a size of 300mm*500mm into deionized water for ultrasonic cleaning for 120 minutes, put it in an oven at 120°C for 8 hours, and place it in a desiccator for later use.

[0058] (2) Add 600 mg of graphene oxide to 600 ml of ethanol, and use ultrasonic treatment at a frequency of 20000 Hz for 30 min to prepare a dispersion with a graphene oxide content of 1 mg / ml.

[0059](3) Pour 600ml of the prepared dispersion into a square container with a size of 300mm*500mm*50mm, immerse the polyacrylonitrile graphite felt after ultrasonic cleaning into the solution to a depth of 4mm, soak for 1 hour, and then The container containing the dispersion liquid and polyacrylonitrile graphite felt was placed in an oven at 70°C, and heated for 24 hours to remove the solvent, so as to prepare a graphene oxide-polyacrylonitrile graphite felt composite porous electrode.

[0060] (4) The porous composite porous electrode w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com