Method for preparing yeast cell wall beta-1,3-dextran

A technology of yeast cell wall and dextran, which is applied in fermentation and other directions, can solve the problems of inconvenient industrial scale use of technology, few industrial scale research, and inconvenient source of raw materials, so as to save equipment investment, large amount of raw materials, and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

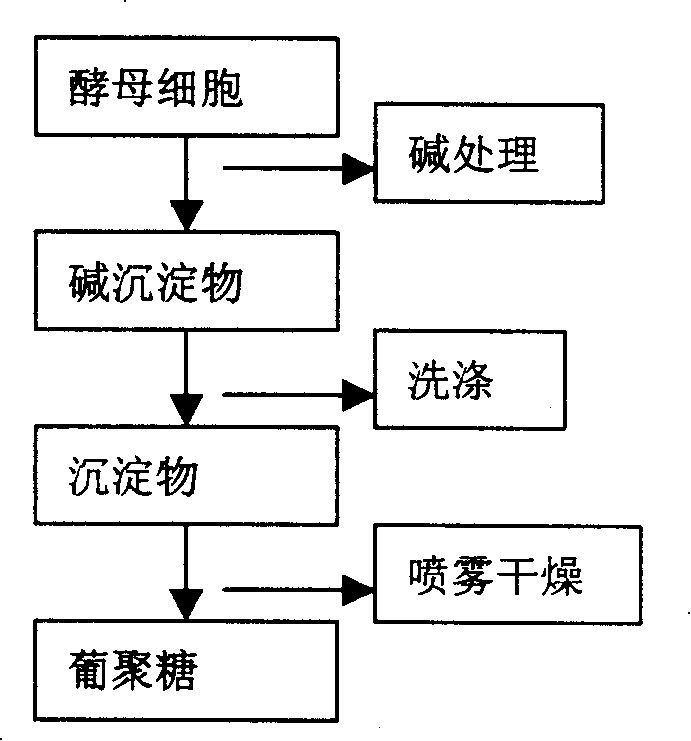

Image

Examples

Embodiment 1

[0027] Take 500g of beer dry yeast and add 4.5 liters of water, mix evenly, remove impurities such as wheat husk through an 80-mesh sieve, then add NaOH to make the final concentration of NaOH 4%, heat to 100°C, stir at 350 rpm for 3 hours, and let stand Overnight, discard the supernatant the next day, pour the same amount of water as the discarded supernatant, add NaOH to make the final concentration 4%, heat to 100°C, stir at 350 rpm for 3 hours, let stand and discard Remove the supernatant, pour in clean water, repeatedly wash the obtained sediment, and spray dry to obtain dextran.

Embodiment 2

[0029] Take 500g of beer dry yeast and add 4.5 liters of water. After mixing evenly, remove impurities such as wheat husks through a 60-mesh sieve, then add NaOH to make the final concentration of NaOH 4.5%, heat to 110°C, and stir at 300 rpm for 3.5h. Leave it overnight, discard the supernatant the next day, pour in the same amount of water as the discarded supernatant, add NaOH to make the final concentration 5%, heat to 110°C, stir at 350 rpm for 3 hours, and let it stand The supernatant was discarded, poured into clean water, the sediment obtained was repeatedly washed, and spray-dried to obtain dextran.

Embodiment 3

[0031] Take 1Kg of beer dry yeast and add 4.5 liters of water, mix well, remove impurities such as wheat husk through an 80-mesh sieve, then add NaOH to adjust the pH value to 8, add alkaline protease, and react at 55°C for 2 hours; add 5L of water, then add NaOH made the suspension concentration 1%, heated to 100°C, stirred and reacted at 300 rpm for 3 hours, left to stand and discarded the supernatant, poured into clean water, repeatedly washed the sediment obtained, and spray-dried to obtain dextran.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com