Preparation method of modified ZSM-5 zeolite toluene disproportionation catalyst by soda treatment

A technology of toluene disproportionation and ZSM-5 is applied in the field of preparation of ZSM-5 molecular sieve modified catalyst, which can solve the problems of decreasing conversion rate and aggravating the degree of side reactions, and achieve the effect of mild treatment conditions and simple steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

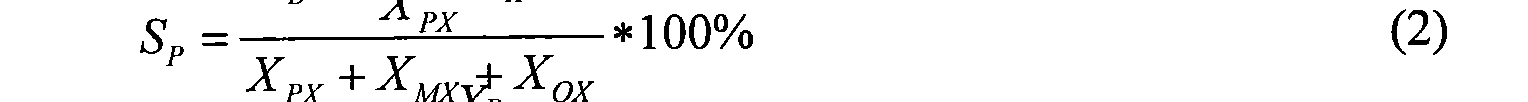

Image

Examples

Embodiment 1

[0032] Mix 30g HZSM-5 zeolite molecular sieve raw powder (manufactured by Catalyst Factory of Nankai University, the molar ratio of silicon oxide to aluminum oxide is 38) with 25g silica sol, 1.2g squash powder, mix evenly, extrude and form, and make the binder Strip catalyst solid particles with a content of 20%. The above catalyst is exchanged for ammonium ion in ammonium chloride solution (the weight ratio of ammonium chloride to solid is 1:1), then washed, centrifuged, dried and roasted. The catalyst was pickled in 0.5mol / L oxalic acid solution, the solid-to-liquid ratio was 1:5, then washed, filtered, and dried, and chemical liquid phase deposition was performed twice with cyclohexane solution of tetraethyl orthosilicate, modified for 5 hours, The deposition temperature is 45°C, dried at 120°C for 6 hours, heated at 1°C / min to 550°C for 4 hours and calcined to obtain the final catalyst A.

[0033] The toluene disproportionation reaction was carried out on a high-pressure...

Embodiment 2

[0045] Mix 30g of HZSM-5 zeolite molecular sieve raw powder (manufactured by Nankai University Catalyst Factory, the molar ratio of silicon oxide to aluminum oxide is 38) and 0.2mol / L sodium hydroxide solution to form a suspension, the solid-to-liquid ratio is 1:10, Stir at 65°C for 0.5h, filter, wash, dry in an oven at 100-120°C for 2-5h, heat up to 550°C at 2°C / min in a muffle furnace, and bake at this temperature for 3-5h.

[0046] The powder thus obtained was subjected to ammonium exchange, extruded, dried, calcined and then exchanged, pickled and deposited according to a binder content of 20%, to obtain catalyst sample B.

Embodiment 3

[0048] 30g HZSM-5 zeolite molecular sieve raw powder (manufactured by Catalyst Factory of Nankai University, the molar ratio of silicon oxide to aluminum oxide is 38) was added to 25g silica sol, and 1.2g kale powder was formed (binder content 20%). The formed solid is dried and roasted.

[0049] Take 5 g of the above solid in 0.05 mol / L sodium hydroxide solution and shake at a constant speed for 2 h at 45 °C with a solid-to-liquid ratio of 1:10. Then wash, dry and roast. The obtained solid was exchanged with ammonium 6 times, washed with acid, and deposited twice. After deposition, a bar-shaped alkali-treated catalyst sample C was obtained.

[0050] Get 2 grams of above-mentioned catalysts to carry out toluene disproportionation reaction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com