Extracting method of synthetic peach aldehyde

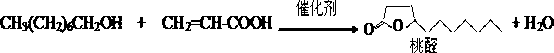

An extraction method and peach aldehyde technology, applied in the industrial field, can solve the problems of low synthetic reaction yield, high production cost, and soft peach aldehyde aroma, and achieve the effects of mild treatment conditions, low equipment requirements, and low treatment costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

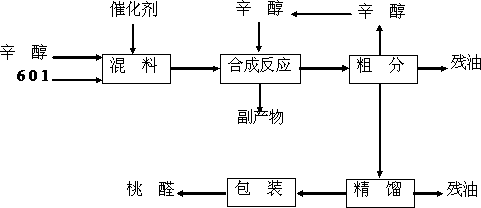

Method used

Image

Examples

Embodiment 1

[0028] 1. Put 218g of octanol, 67g of acrylic acid, and 9g of peroxide in a 500ml flask, and fully stir with a stirrer to make it evenly mixed.

[0029] 2. In a 1000ml three-necked flask equipped with a stirrer, a reflux condensing device and a dripping device, add 510 g of octanol and 0.5 g of a co-catalyst. Start the stirrer, heat the material to 160°C, and drop the mixture of octanol, acrylic acid and peroxide into the three-necked flask within 7 hours. Under stirring, the reaction is refluxed until no water and the like are distilled out in the by-product collector, that is, the reaction is terminated. A peachaldehyde-containing reaction mixture is obtained.

[0030] 3. The above-mentioned reaction mixture was transferred into the vacuum distillation apparatus, and under the vacuum of 133.3Pa, unreacted octanol was recovered by distillation to obtain 583g of octanol.

[0031] 4, the above-mentioned reaction mixture after the recovery of octanol is transferred into the va...

Embodiment 2

[0034] 1. Put 230g of octanol, 70g of acrylic acid, and 14g of peroxide into a 500ml flask, and fully stir with a stirrer to make it evenly mixed.

[0035] 2. In a 1000ml three-necked flask equipped with a stirrer, a reflux condensing device and a dripping device, add 500 g of octanol and 1.0 g of a co-catalyst. Start the stirrer, heat the material to 180°C, and drop the mixture of octanol, acrylic acid and peroxide into the three-necked flask within 5 hours. Under stirring, the reaction is refluxed until no water and the like are distilled out in the by-product collector, that is, the reaction is terminated. A peachaldehyde-containing reaction mixture is obtained.

[0036] 3. The above-mentioned reaction mixture was transferred into a vacuum distillation apparatus, and under the vacuum of 0-133.3Pa, unreacted octanol was recovered by distillation to obtain 589g of octanol.

[0037] 4, the above-mentioned reaction mixture after the recovery of octanol is transferred into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com