Microwave-induced catalytic oxidization method of high-concentration organic wastewater

A technology for inducing catalysis and organic wastewater, applied in chemical instruments and methods, oxidized water/sewage treatment, physical/chemical process catalysts, etc., can solve the problems of complex catalyst preparation, large dosage, low recovery rate, etc., and achieve high strength, The effect of short balance time and easy regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

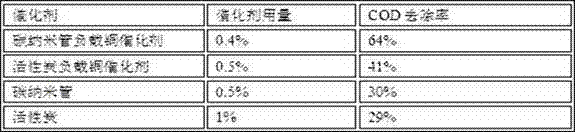

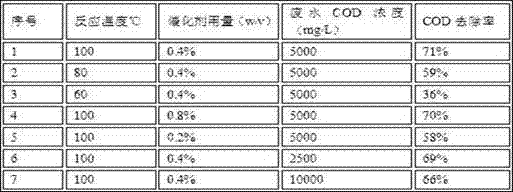

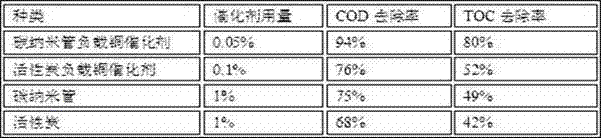

Examples

Embodiment 1

[0037] Preparation of Platinum Catalysts Supported by Carbon Nanotubes

[0038] Weigh 0.4 g of carbon nanotubes, add 200 ml of ethylene glycol, add 0.4 ml of 0.05 M chloroplatinic acid while stirring, ultrasonicate for 10 min, stir and slowly add NaOH saturated solution dropwise until the pH is 12. Put it into the microwave at a power of 700W and stabilize it for 75s, take it out and cool it to room temperature, filter it with suction, and wash it with acetone three times. Finally, put the obtained solid into a blast drying oven at 85° C. to dry, and the obtained sample is the platinum catalyst supported by carbon nanotubes.

[0039] Carbon nanotube supported platinum catalyst catalytic air oxidation laboratory simulation of organic wastewater

[0040]Prepare 2000mg / L phenol solution (COD about 5000mg / L) as simulated organic wastewater, take 30ml of the solution, add 0.12g of the above catalyst, ultrasonicate for 5min, stir and absorb at room temperature, then filter. In add...

Embodiment 2

[0042] Preparation of Copper Catalyst Supported by Carbon Nanotubes

[0043] Weigh 8.5g of copper nitrate trihydrate, add 70ml of water to make a solution, add 1.0g of carbon nanotubes, stir at room temperature, filter with suction, wash the filter cake with water, filter, and put it in a blast drying oven for drying. The above solid was taken out and put into a three-necked flask, placed in a microwave reactor, under a nitrogen flow, and stabilized at a microwave power of 700W for 2 minutes, to obtain a carbon nanotube-supported copper catalyst.

[0044] Carbon nanotube-supported copper catalyst catalyzed air oxidation laboratory simulated wastewater

[0045] Prepare 2000mg / L phenol solution (COD about 5000mg / L) as simulated organic wastewater, take 30ml of the solution, add 0.12g of the above catalyst, ultrasonicate for 5min, stir and absorb at room temperature, then filter. Add the above solid to 30 ml of the phenol solution, place it in a microwave reactor, let air in, ad...

Embodiment 3

[0047] Preparation of Iron Catalyst Supported by Carbon Nanotubes

[0048] Take 43.7ml of 65% concentrated nitric acid solution and add 70ml of water to form a solution, weigh 14.14g of ferric nitrate nonahydrate into the solution and stir to dissolve, add 1.0g of carbon nanotubes, stir, and filter. The filter cake is washed with water and then filtered. Dry in a blast drying oven. The above was taken out and put into a three-necked flask, placed in a microwave reactor, under a nitrogen flow, and stabilized for 2 minutes at a microwave power of 700W, to obtain a carbon nanotube-supported iron catalyst.

[0049] Carbon nanotube-supported iron catalyst catalyzed air oxidation laboratory simulated wastewater

[0050] Prepare 2000mg / L phenol solution (COD about 5000mg / L) as simulated organic wastewater, take 30ml of the solution, add 0.12g of the above catalyst, ultrasonicate for 5min, stir and absorb at room temperature, then filter. Another 30 ml of phenol solution was added ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com