Fluorine-containing polymer for photoresist, top anti-reflection film composition containing fluorine-containing polymer and application of fluorine-containing polymer in photoresist

An anti-reflection film and polymer technology, applied in photosensitive materials for optomechanical equipment, optics, optomechanical equipment, etc., can solve problems such as processability, film-forming refractive index or insufficient raw material cost, and avoid standing Effect of wave effect, low toxicity, and low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

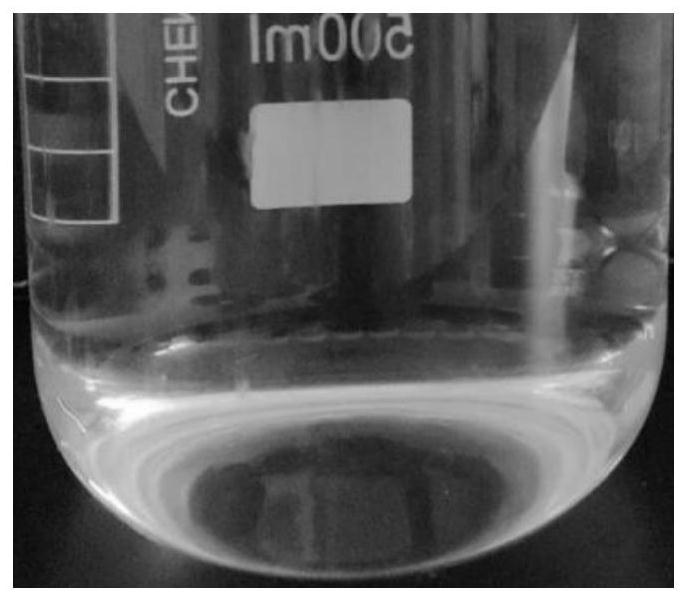

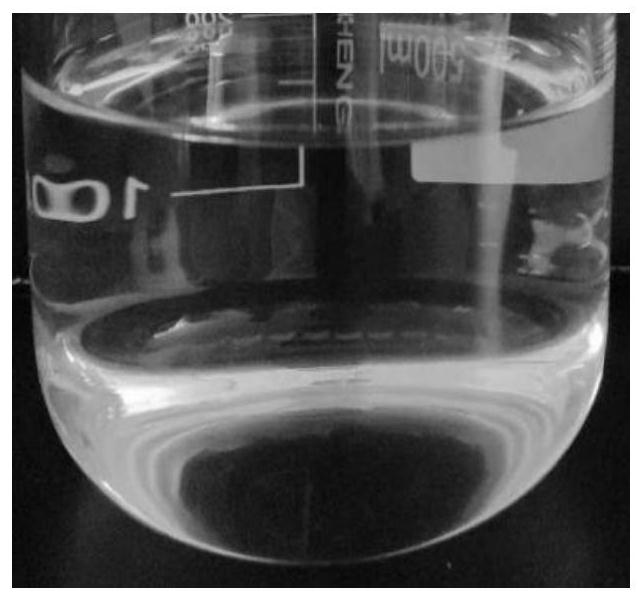

Image

Examples

preparation example Construction

[0040] Preparation of perfluoropolyether carboxylic acid:

[0041] First add 50ml of acetonitrile and 50ml of tetraethylene glycol dimethyl ether into a 1L polymerization kettle, then add 5g of catalyst KF into the polymerization kettle, stir and mix evenly, replace with high-purity nitrogen three times, and pump negative pressure to -0.1MPa , cooled to the set temperature of 0°C, and 50g of hexafluoropropylene oxide was introduced. Timed feeding (50g / h) was adopted to control the reaction process, and the temperature was controlled between 0 and 10°C. After adding hexafluoropropylene oxide to 1000g, return to normal pressure, after the completion of the reaction, keep stirring for two hours, stop stirring, return to room temperature, and obtain the mixture.

[0042] The mixture is layered, the reaction product in the lower layer is separated by centrifugation and filtration, and the reaction product is added to the distillation device. Perfluoropolyetheryl fluoride with a p...

Embodiment 1

[0048] The above-mentioned perfluoropolyether carboxylic acids with different degrees of polymerization are mixed, and the mixing ratio is as follows: by weight, 10% perfluoropolyether carboxylic acid A, 66% perfluoropolyether carboxylic acid B, 19% perfluoropolyether carboxylic acid Ether carboxylic acid C, 1% perfluoropolyether carboxylic acid D, 4% perfluoropolyether carboxylic acid E. The perfluoropolyether carboxylic acid was thus obtained, the specific composition of which is shown in Table 1.

Embodiment 2

[0050] The above-mentioned perfluoropolyether carboxylic acids with different degrees of polymerization are mixed, and the mixing ratio is as follows: by weight, 4% perfluoropolyether carboxylic acid A, 58% perfluoropolyether carboxylic acid B, 28% perfluoropolyether carboxylic acid Ether carboxylic acid C, 8% perfluoropolyether carboxylic acid D, 2% perfluoropolyether carboxylic acid F. The perfluoropolyether carboxylic acid was thus obtained, the specific composition of which is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com