Method for treating high-salt ammonia nitrogen wastewater and comprehensively utilizing fluorine-silicon resources

An ammonia nitrogen wastewater and high-salt technology, applied in heating water/sewage treatment, oxidized water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of unrecycled salt, high treatment cost, complicated process, etc. Achieve the effect of realizing reuse, reducing ammonia nitrogen and salt content, and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

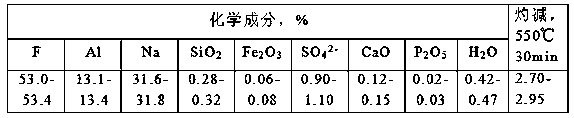

[0029] Example 1: A method for the treatment of high-salt ammonia nitrogen wastewater and the comprehensive utilization of fluorine and silicon resources:

[0030] The high-salt ammonia nitrogen wastewater in this example includes the following components in mass percentage: 1) 20% ammonium chloride; 2) 25% sodium chloride.

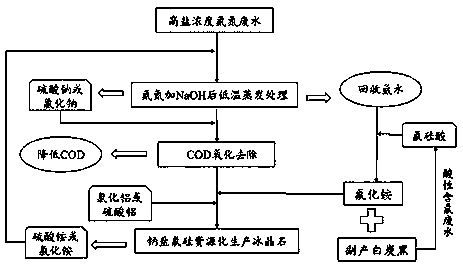

[0031] The method for the treatment of high-salt ammonia nitrogen wastewater and the comprehensive utilization of fluorine and silicon resources in this embodiment includes the following steps:

[0032](1) Ammonia nitrogen treatment: add 150 g of sodium hydroxide to 1000 g of the above-mentioned high-salt ammonia-nitrogen wastewater (that is, the mass ratio of sodium hydroxide to high-salt ammonia-nitrogen wastewater is 1:6.67), enter the ammonia recovery system, and the ammonia nitrogen in the wastewater Recover ammonia water by low-temperature evaporation; in this step, the ammonium chloride component in the high-salt ammonia-nitrogen wastewater reacts ...

Embodiment 2

[0040] Example 2: A method for the treatment of high-salt ammonia nitrogen wastewater and the comprehensive utilization of fluorine and silicon resources:

[0041] The high-salt ammonia-nitrogen wastewater in this example includes the following components in mass percentage: 1) 4% ammonium chloride; 2) 10% sodium chloride.

[0042] The method for the treatment of high-salt ammonia nitrogen wastewater and the comprehensive utilization of fluorine and silicon resources in this embodiment includes the following steps:

[0043] (1) Ammonia nitrogen treatment: add 30 g of sodium hydroxide to 1000 g of the above-mentioned high-salt ammonia-nitrogen wastewater (that is, the mass ratio of sodium hydroxide to high-salt ammonia-nitrogen wastewater is 1:33.3), enter the ammonia recovery system, and the ammonia nitrogen in the wastewater Separately recover ammonia water by low-temperature evaporation; in this step, the ammonium chloride component in the high-salt ammonia-nitrogen wastewat...

Embodiment 3

[0051] Example 3: A method for the treatment of high-salt ammonia nitrogen wastewater and the comprehensive utilization of fluorine and silicon resources:

[0052] The high-salt ammonia nitrogen wastewater in this example includes the following components in mass percentage: 1) 12% ammonium chloride; 2) 15% sodium chloride.

[0053] The method for the treatment of high-salt ammonia nitrogen wastewater and the comprehensive utilization of fluorine and silicon resources in this embodiment includes the following steps:

[0054] (1) Ammonia nitrogen treatment: add 90 g of sodium hydroxide to 1000 g of the above-mentioned high-salt ammonia-nitrogen wastewater (that is, the mass ratio of sodium hydroxide to high-salt ammonia-nitrogen wastewater is 1:11.1), enter the ammonia recovery system, and the ammonia nitrogen in the wastewater Separately recover ammonia water by low-temperature evaporation; in this step, the ammonium chloride component in the high-salt ammonia-nitrogen wastewa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com