Method for refining and purifying etching waste liquid

A technology for refining, purifying and etching waste liquid, which is applied in chemical instruments and methods, ammonium fluoride, ammonium halide and other directions to achieve the effects of high product utilization value, extended application fields and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

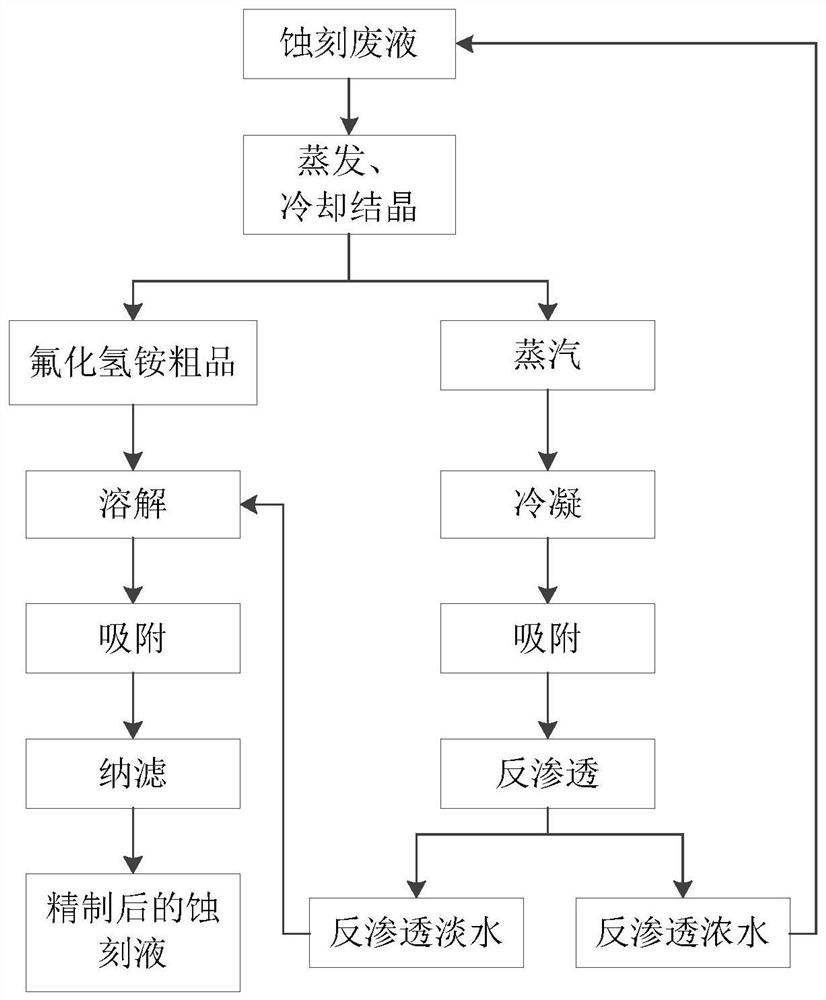

[0066] This embodiment provides a method for refining and purifying etching waste liquid, the process flow chart of the method is as follows figure 1 shown, including the following steps:

[0067] (1) Evaporate the waste liquid that semiconductor silicon chip etching process produces, the composition of the etchant that described etching process adopts comprises hydrofluoric acid, ammonium bifluoride and sodium dodecylbenzene sulfonate, and the temperature of described evaporation process is 90°C to obtain steam and evaporated concentrated liquid, the concentration of the evaporated concentrated liquid is 65wt%, and the pH value is 3.5, and the evaporated concentrated liquid is subjected to cooling and crystallization, and the cooling rate of the cooling crystallization is 10°C / h, and the temperature is reduced to At 25°C, the crude product of ammonium bifluoride was obtained with a purity of 97.0wt%;

[0068] (2) The ammonium bifluoride crude product obtained in step (1) is ...

Embodiment 2

[0072] This embodiment provides a method for refining and purifying etching waste liquid, said method comprising the following steps:

[0073] (1) Evaporate the waste liquid produced by the semiconductor silicon chip etching process, the composition of the etchant used in the etching process includes hydrofluoric acid, ammonium fluoride and sodium dodecylbenzenesulfonate, the temperature of the evaporation process at 100°C to obtain steam and evaporated concentrated liquid, the concentration of the evaporated concentrated liquid is 80wt%, and the pH value is 3, and the evaporated concentrated liquid is subjected to cooling crystallization, and the cooling rate of the cooling crystallization is 15°C / h. to 20°C, the crude product of ammonium bifluoride was obtained with a purity of 97.8wt%;

[0074] (2) The ammonium bifluoride crude product obtained in step (1) is redissolved in water, and activated carbon is used for adsorption. The adsorbate is the organic matter added in the ...

Embodiment 3

[0078] This embodiment provides a method for refining and purifying etching waste liquid, said method comprising the following steps:

[0079] (1) Evaporate the waste liquid produced by the semiconductor silicon chip etching process, the composition of the etchant used in the etching process includes ammonium fluoride, ammonium bifluoride and sodium lauryl sulfate, and the temperature of the evaporation treatment is 80 ° C , to obtain steam and evaporated concentrated liquid, the concentration of the evaporated concentrated liquid is 50wt%, and the pH value is 4, and the evaporated concentrated liquid is subjected to cooling and crystallization, and the cooling rate of the cooling crystallization is 5°C / h, and the temperature is lowered to 30°C , to obtain ammonium bifluoride crude product, its purity is 96.2wt%;

[0080] (2) After condensing the steam obtained in step (1) to obtain a condensate, the condensate is a fluorine-containing ammonia solution, and the condensate is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com