System for preparing ammonium bifluoride by utilizing BOE waste liquid

A technology of ammonium bifluoride and waste liquid, which is applied in the direction of ammonium fluoride, ammonium halide, chemical instruments and methods, etc., can solve the problems of high investment cost, high equipment requirements, and small investment cost, so as to avoid and reduce environmental pollution , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

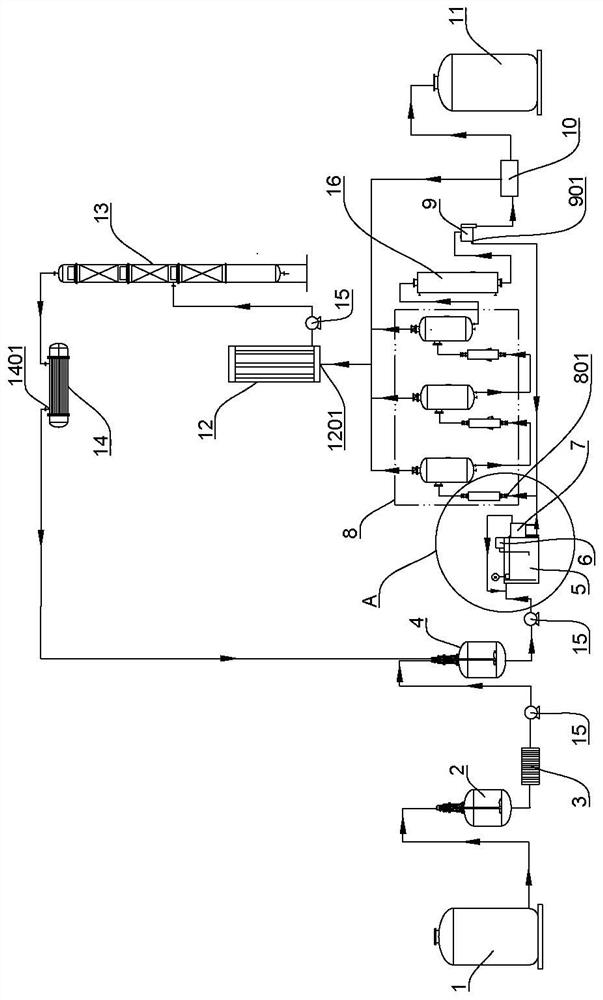

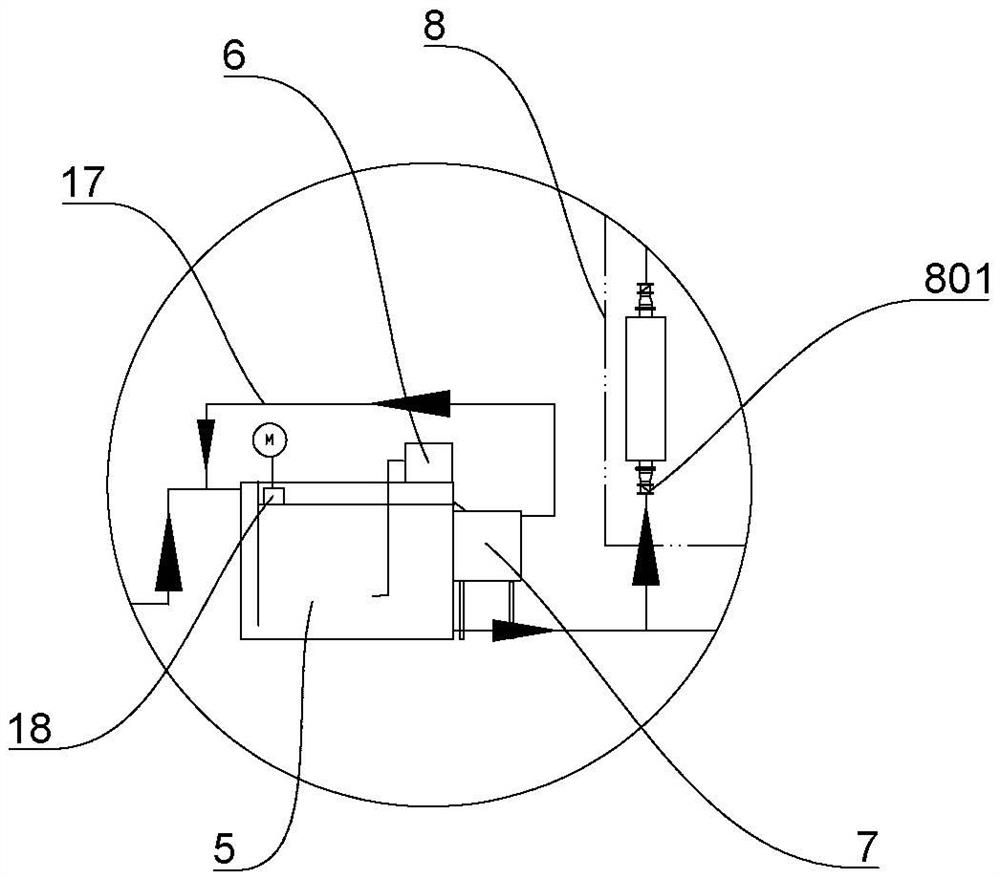

[0019] Below in conjunction with the processing method and accompanying drawing that utilize BOE waste liquid to prepare ammonium bifluoride, the present invention will be further described:

[0020] The method for preparing ammonium bifluoride by utilizing BOE waste liquid comprises the following steps:

[0021] S1: Add barium hydroxide into the first reaction kettle with BOE waste liquid, stir for 30-60 minutes, and then filter to obtain the filtrate. The BOE waste liquid contains 0.1%-5% ammonium fluorosilicate, 0.1%- 5% ammonium sulfate, 10%~30% ammonium fluoride and 5%~20% ammonium bifluoride;

[0022] S2: Put the filtrate in the second reaction kettle, pass through anhydrous hydrogen fluoride, mix uniformly and react at 30°C-60°C until the pH of the mixed solution reaches 4-5, and obtain an ammonium bifluoride solution;

[0023] S3: Evaporate the ammonium bifluoride solution under reduced pressure in a three-effect evaporator, the evaporation time is 30-60min, the evapo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com