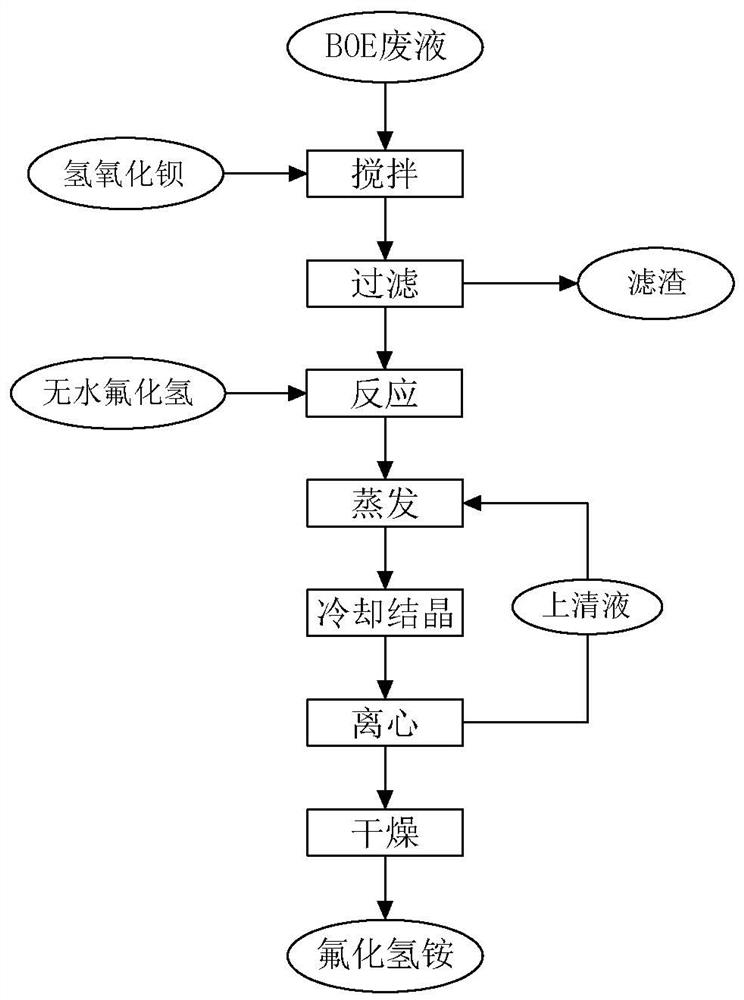

Method for preparing ammonium bifluoride by utilizing BOE waste liquid

A technology of ammonium bifluoride and anhydrous hydrogen fluoride, which is applied in the direction of ammonium fluoride and ammonium halide, can solve the problems of high equipment requirements, large investment costs, high production costs, etc., and achieve the goal of reducing production costs, avoiding environmental pollution, and mild process conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

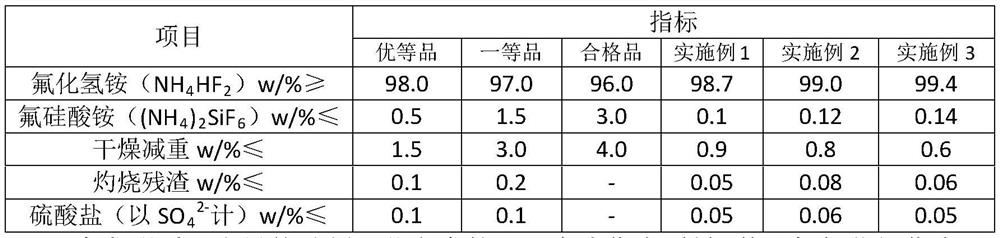

Embodiment 1

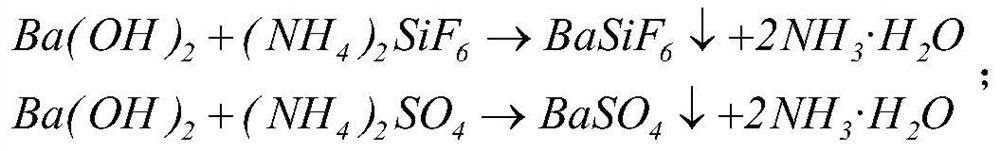

[0023] Add 4.56kg of barium hydroxide to 1 ton of BOE waste liquid containing 0.1% ammonium fluorosilicate, 0.3% ammonium sulfate, 15% ammonium fluoride and 6% ammonium bifluoride in mass fraction, and the addition amount of barium hydroxide is theoretical 94% of the value, stirred for 30 minutes, and after filtration, separated and removed barium sulfate and barium hexafluorosilicate precipitated filter residue to obtain a filtrate containing ammonium fluoride and ammonium bifluoride.

[0024] The filtrate was placed in a water-cooled reactor, fed with anhydrous hydrogen fluoride, mixed uniformly and fully reacted at 30°C until the pH of the mixed solution reached 4, and then stopped feeding anhydrous hydrogen fluoride to obtain an ammonium bifluoride solution.

[0025] Evaporate the ammonium bifluoride solution under reduced pressure in the three-effect evaporator, the evaporation time is 30min, the temperature is 70°C, and the pressure is -0.03Mpa to obtain the ammonium bifl...

Embodiment 2

[0028] Add 55.81 kg of barium hydroxide to 1 ton of BOE waste liquid containing 2% ammonium fluorosilicate, 3% ammonium sulfate, 21% ammonium fluoride and 12% ammonium bifluoride in mass fraction, and the addition amount of barium hydroxide is theoretical 96% of the value, stirred for 40 minutes, and after filtration, separated and removed barium sulfate and barium hexafluorosilicate precipitated filter residue to obtain a filtrate containing ammonium fluoride and ammonium bifluoride.

[0029] The filtrate was placed in a water-cooled reactor, fed with anhydrous hydrogen fluoride, mixed uniformly and fully reacted at 50°C until the pH of the mixed solution reached 5, then stopped feeding anhydrous hydrogen fluoride to obtain an ammonium bifluoride solution.

[0030] Evaporate the ammonium bifluoride solution under reduced pressure in the three-effect evaporator, the evaporation time is 50min, the temperature is 90°C, and the pressure is -0.05Mpa to obtain the ammonium bifluorid...

Embodiment 3

[0033] Add 97.96kg of barium hydroxide to 1 ton of BOE waste liquid containing 5% ammonium fluorosilicate, 4% ammonium sulfate, 25% ammonium fluoride and 15% ammonium bifluoride in mass fraction, and the addition amount of barium hydroxide is theoretical 99% of the value, stirred for 60 minutes, and after filtration, the precipitated filter residue of barium sulfate and barium hexafluorosilicate was separated and removed to obtain a filtrate containing ammonium fluoride and ammonium bifluoride.

[0034] The filtrate was placed in a water-cooled reactor, fed with anhydrous hydrogen fluoride, mixed uniformly and fully reacted at 60°C until the pH of the mixed solution reached 4.5, then stopped feeding anhydrous hydrogen fluoride to obtain ammonium bifluoride solution.

[0035] Evaporate the ammonium bifluoride solution under reduced pressure in the three-effect evaporator, the evaporation time is 60min, the temperature is 120°C, and the pressure is -0.06Mpa to obtain the ammonium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com