Resourceful treatment method of waste salt

A treatment method and resource recovery technology, applied in the field of resource recovery of waste salt, can solve problems such as unconsidered state and environment, high cost and energy consumption, and low practicability, and achieve low cost and improved resource recovery , the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

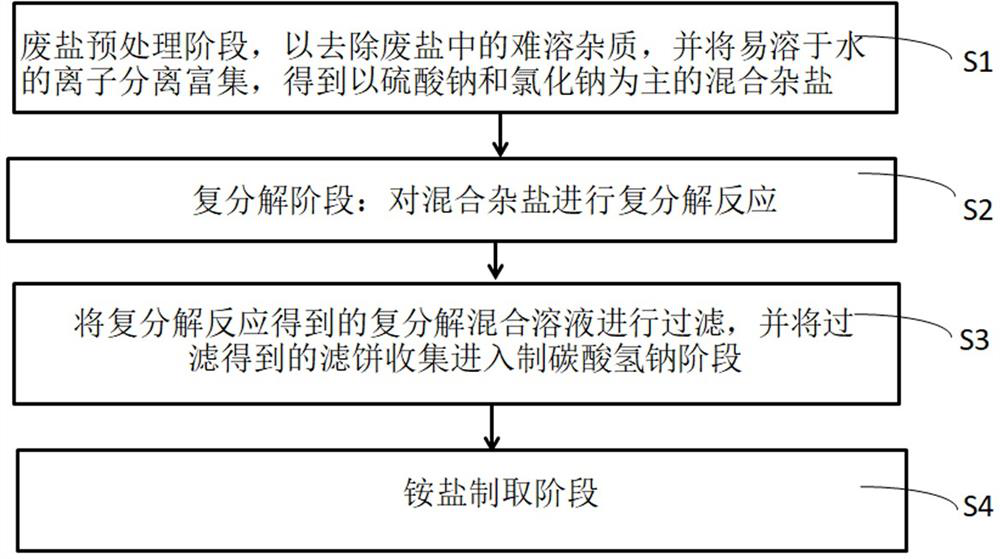

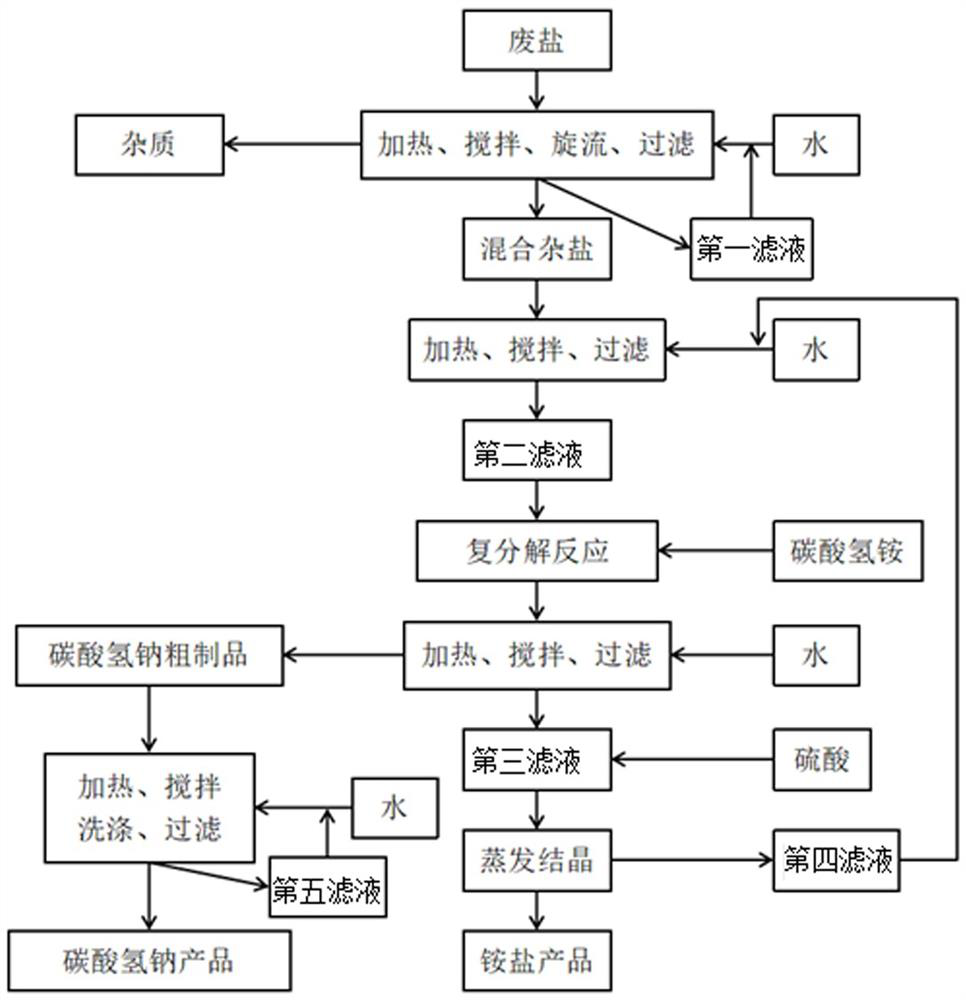

[0042] Such as figure 2 As shown, the waste salt recycling method of the present invention includes the following steps: mix waste salt and water according to equal mass, fully stir for 3 hours at a temperature of 80°C and a rotation speed of 227rpm to obtain waste salt water, and then use a cyclone The insoluble impurities are removed from the waste brine, and the ions that are easily soluble in water are separated and enriched by the method of filtration and water recycling to obtain mixed miscellaneous salts. Dissolve the mixed miscellaneous salt in water, the quality of the water is 2.5 times the mass of the mixed miscellaneous salt, stir at 35°C and 227rpm for 1h, filter to obtain the second filtrate, and slowly add the mass of the mixed miscellaneous salt to the second filtrate under the same conditions. Ammonium bicarbonate with 1.06 times the salt mass was reacted for 3 hours. The crude product of sodium bicarbonate and the third filtrate were obtained by filtration,...

Embodiment 2

[0045] The waste salt resource treatment method of the present invention comprises the following steps: mix waste salt and water according to a mass ratio of 1:1.25, fully stir for 3 hours at a temperature of 84°C and a rotation speed of 275rpm to obtain waste salt water, and then use a cyclone The insoluble impurities are removed from the waste brine, and the ions that are easily soluble in water are separated and enriched by the method of filtration and water recycling to obtain mixed miscellaneous salts. Dissolve the mixed miscellaneous salt in water, the quality of the water is 3.2 times the mass of the mixed miscellaneous salt, stir for 40min at a temperature of 37°C and a rotation speed of 200rpm, filter to obtain the second filtrate, and slowly add the mass of Mix ammonium bicarbonate 1.20 times the mass of the miscellaneous salt and react for 2.5 hours. The crude product of sodium bicarbonate and the third filtrate were obtained by filtration. Under the heating and sti...

Embodiment 3

[0048] The recycling treatment method of waste salt of the present invention comprises the following steps:

[0049] Mix the waste salt and water according to the mass ratio of 1:1.1, fully stir for 2.1 hours at a temperature of 85°C and a rotation speed of 350rpm to obtain waste salt water, and then use a cyclone to remove insoluble impurities in the waste salt water, and use filtration and circulation Water-soluble ions are separated and enriched to obtain mixed miscellaneous salts. Dissolve the mixed miscellaneous salt in water, the quality of the water is 4 times the mass of the mixed miscellaneous salt, stir at a temperature of 35°C and a rotation speed of 250rpm for 0.5h, filter to obtain the second filtrate, and slowly add mass to the second filtrate under the same conditions Ammonium bicarbonate, which is 1.06 times the mass of the mixed miscellaneous salts, was reacted for 3 hours. The crude product of sodium bicarbonate and the third filtrate were obtained by filtra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com