Recycling method for fluorine-containing ammonia-nitrogen-containing wastewater through tantalum-niobium wet-process smelting

A technology for hydrometallurgy and ammonia nitrogen wastewater, which is applied in metallurgical wastewater treatment, neutralized water/sewage treatment, multi-stage water treatment, etc. It can solve the problems of high water content, non-direct reuse of ammonia water and ammonium salt, and high input cost. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

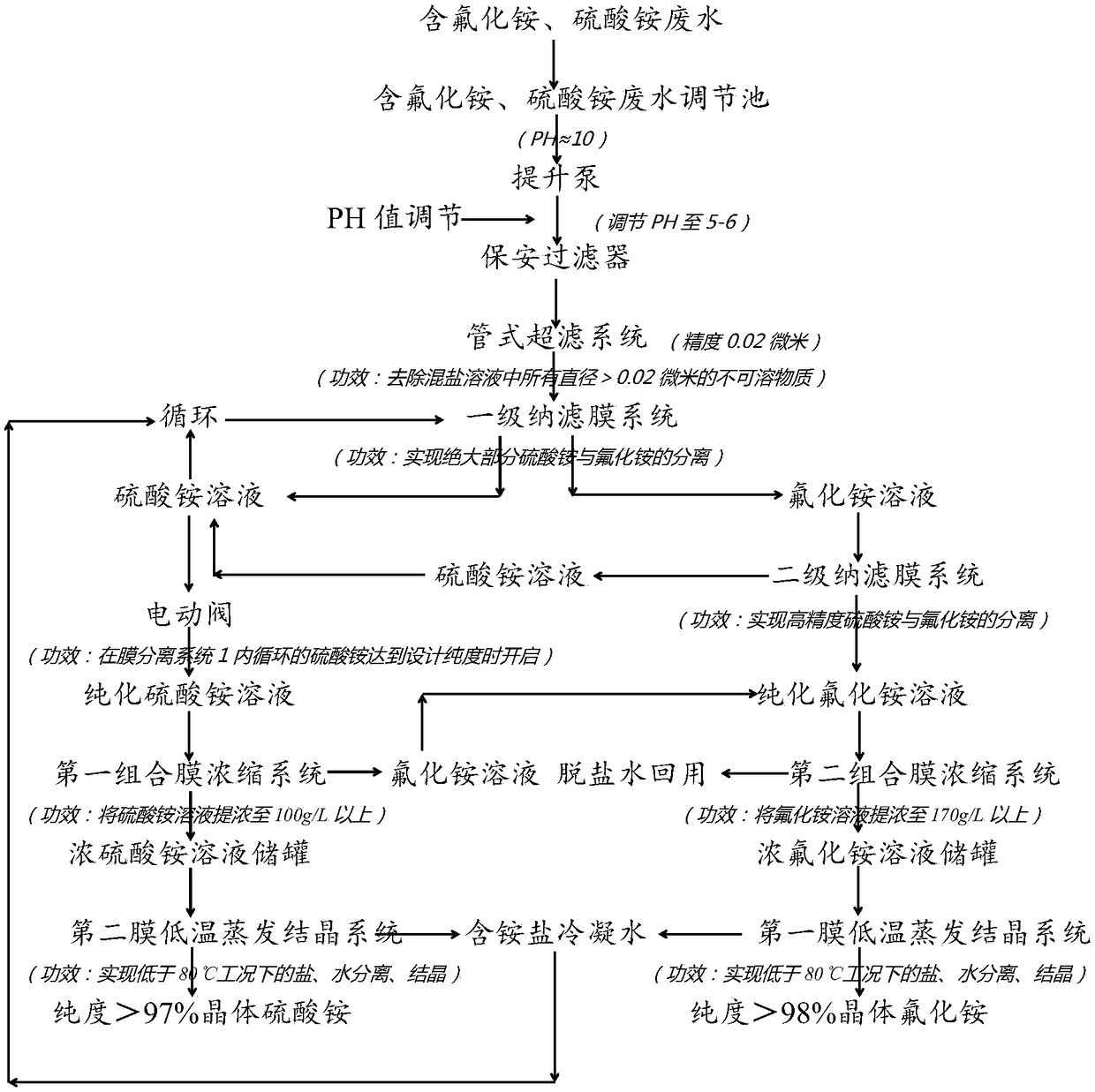

[0021] The embodiment of the present invention provides a method for recycling and treating waste water containing fluorine and ammonia nitrogen in hydrometallurgy of tantalum and niobium, comprising the following steps:

[0022] A method for recycling and treating waste water containing fluorine and ammonia nitrogen in hydrometallurgy of tantalum and niobium, comprising the following steps:

[0023] (1) Add hydrofluoric acid or sulfuric acid to the wastewater to adjust the pH value of the wastewater, adjust the pH value of the wastewater to 5-6, so that the free NH in the wastewater 3 All converted to NH 4 + Soluble in wastewater, that is, converted into water-soluble ammonium sulfate or ammonium fluoride;

[0024] (2) Pass the wastewater after adjusting the pH value into the security filter and the tubular ultrafiltration system to remove most of the insoluble substances in the wastewater;

[0025] (3) Pump the mixed-salt wastewater after impurity removal into the first-l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com