Method for producing electronic-grade ammonium fluoride water solution

A technology of ammonium fluoride and aqueous solution, which is applied in the direction of ammonium fluoride, chemical instruments and methods, ammonium halide, etc., which can solve problems such as unstable product quality, high impurity content, and large fluctuations in purity, and reduce reaction by-products , Improve the quality and high purity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

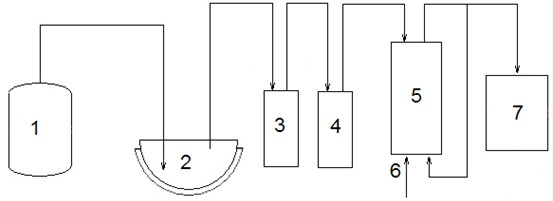

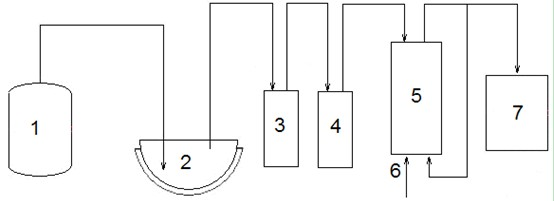

[0033] The industrial-grade liquid ammonia with a concentration of 75% is transported from the industrial-grade liquid ammonia raw material tank 1 to the heating filter 2, the industrial-grade liquid ammonia is heated to 40°C to generate ammonia gas, and the ammonia gas is passed through the The adsorber 3 of woody raw material powdered activated carbon removes organic gas impurities, and then deoxidizes through the deoxygenating adsorber 4 to produce high-purity ammonia gas.

[0034] The high-purity ammonia gas that makes passes into above reactor 5 with the flow rate of 10kg / h, with the high-purity hydrofluoric acid circulation absorption reaction of concentration 40% that passes into from reactor below high-purity hydrofluoric acid inlet 6, condensed water Cool down. After passing the test, the target product ammonium fluoride aqueous solution is collected and stored in the finished product tank 7.

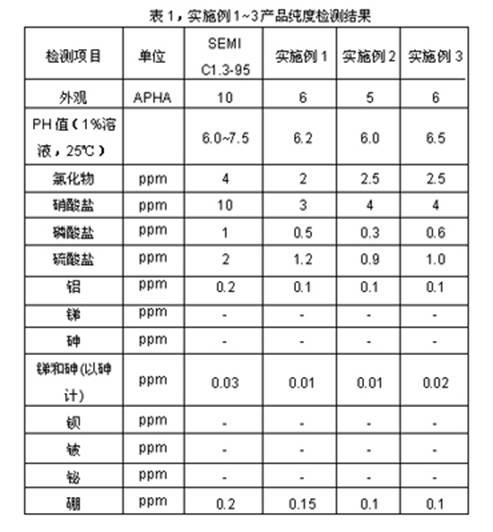

[0035] The concentration of the obtained ammonium fluoride aqueous soluti...

Embodiment 2

[0037] Referring to the method described in Example 1.

[0038] Heating industrial-grade liquid ammonia with a concentration of 80% to 50°C produces ammonia gas, and removes organic gas impurities through an adsorber equipped with sawdust raw material powder activated carbon at 0.12MPa, and then passes through a deoxygenation adsorber to produce high-purity ammonia gas .

[0039] The generated high-purity ammonia gas is passed into the reaction vessel at a flow rate of 13kg / h, and the 50% concentration of high-purity hydrofluoric acid is used to circulate and absorb the reaction, and the condensed water is cooled to lower the temperature. After passing the test, collect the target product ammonium fluoride aqueous solution.

[0040] The concentration of the ammonium fluoride aqueous solution obtained was 50%, the detected metal ion impurity content was 0.1 ppm, and the dust particles larger than 0.5 μm were 3 / ml. The specific inspection results are shown in Table 1.

Embodiment 3

[0042] Referring to the method described in Example 1.

[0043] Heating industrial-grade liquid ammonia with a concentration of 90% to 55°C produces ammonia gas, and removes organic gas impurities through an adsorber equipped with powdered activated carbon of high-quality coal raw materials at 0.15 MPa, and then passes through a deoxygenation adsorber to obtain high-purity Ammonia.

[0044] The generated high-purity ammonia gas is passed into the reaction vessel at a flow rate of 510kg / h, and the high-purity hydrofluoric acid with a concentration of 55% is used to circulate and absorb the reaction, and the condensed water is cooled to lower the temperature. After passing the test, collect the target product ammonium fluoride aqueous solution.

[0045] The obtained ammonium fluoride aqueous solution has a concentration of 55%, the detected metal ion impurity content is less than 0.1 ppm, and the dust particles larger than 0.5 μm are 3 / ml. The specific inspection results are s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com