Method and apparatus for producing nitrogen trifluoride

A technology of nitrogen trifluoride and ammonium bifluoride, which is applied in nitrogen trifluoride, chemical instruments and methods, ammonium fluoride, etc., can solve problems such as shaft seal failure, reliability problems, and high inverse mixing of reaction volume. To achieve the effect of avoiding corrosion problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

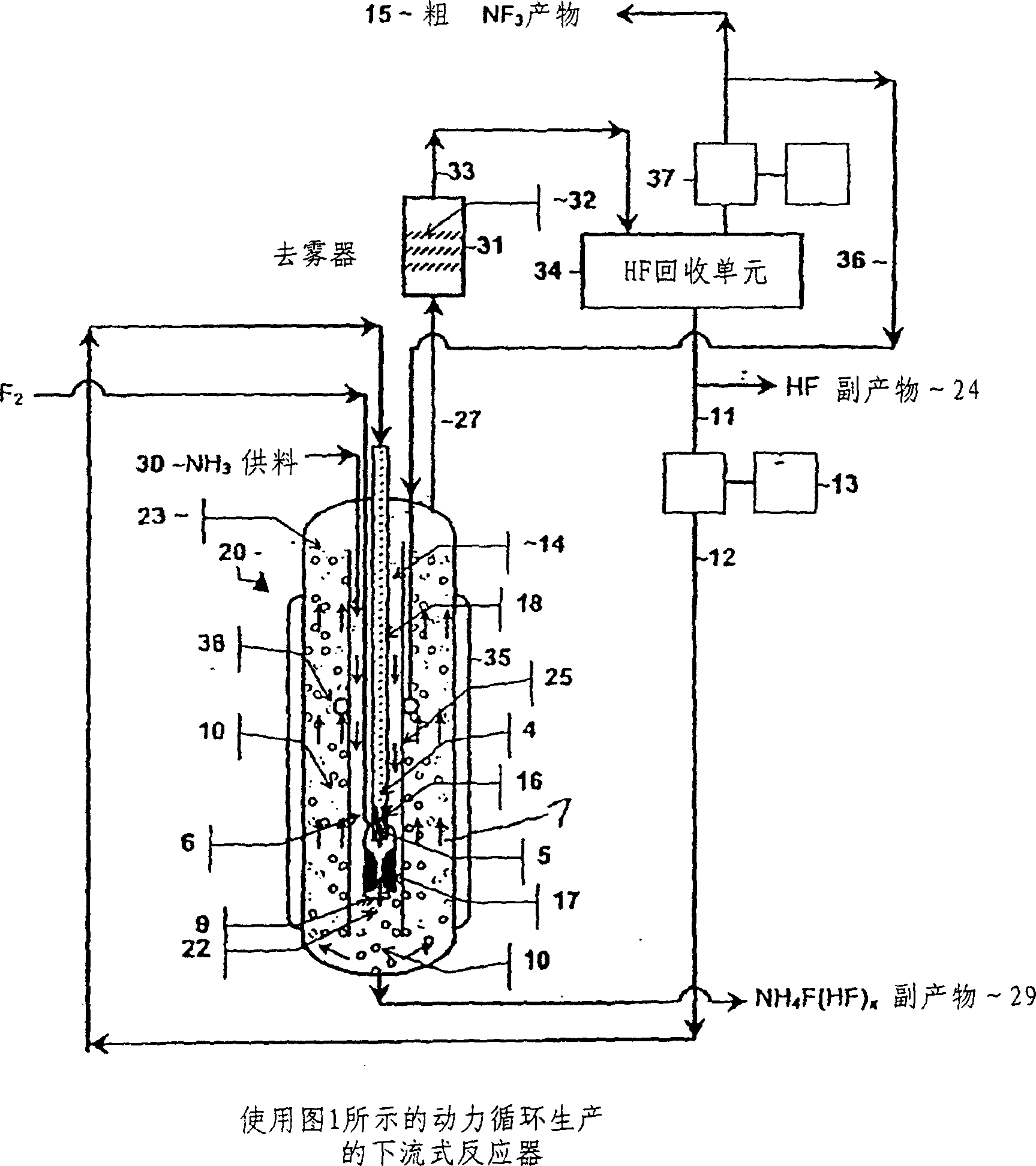

[0064] This example uses something like image 3 reactor structure. NF 3 The reactor was constructed with a 4 meter long, 12 inch diameter schedule 40 monel tube with a flanged top and capped bottom. Spiral steam heating and water cooling coils are attached to the exterior of the reactor with a heat transfer cement. NF 3 Reactor baffles are in NF 3 Bottom of the reactor wall and NF 3 Coaxial 3.3 meter long schedule 10 Monel tubes with a 20 cm gap between the bottoms of the reactor baffle walls. The reactor was installed 0.5 m below the top flange for NH 4 F(HF) x By-product pressure riser (seal leg) overflow pipe. The gas distribution ring for stripping nitrogen is located in an annular gap 3 meters from the center of the top flange, at NF 3 Reactor Wall and NF 3 The reactor walls are approximately equally spaced. The main function of the nitrogen stripping gas is to establish a uniform temperature and suitable NH 4 F(HF) x cycle rate.

[0065] A pressure vessel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com