Cleaning treatment method for ammonium chloride production wastewater

A technology for producing wastewater and cleaning treatment, which is applied to chemical instruments and methods, ammonium fluoride, ammonium halide, etc., can solve the problems of high investment cost and high treatment cost, and achieve low investment cost, low wastewater treatment cost, advanced technology and equipment simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

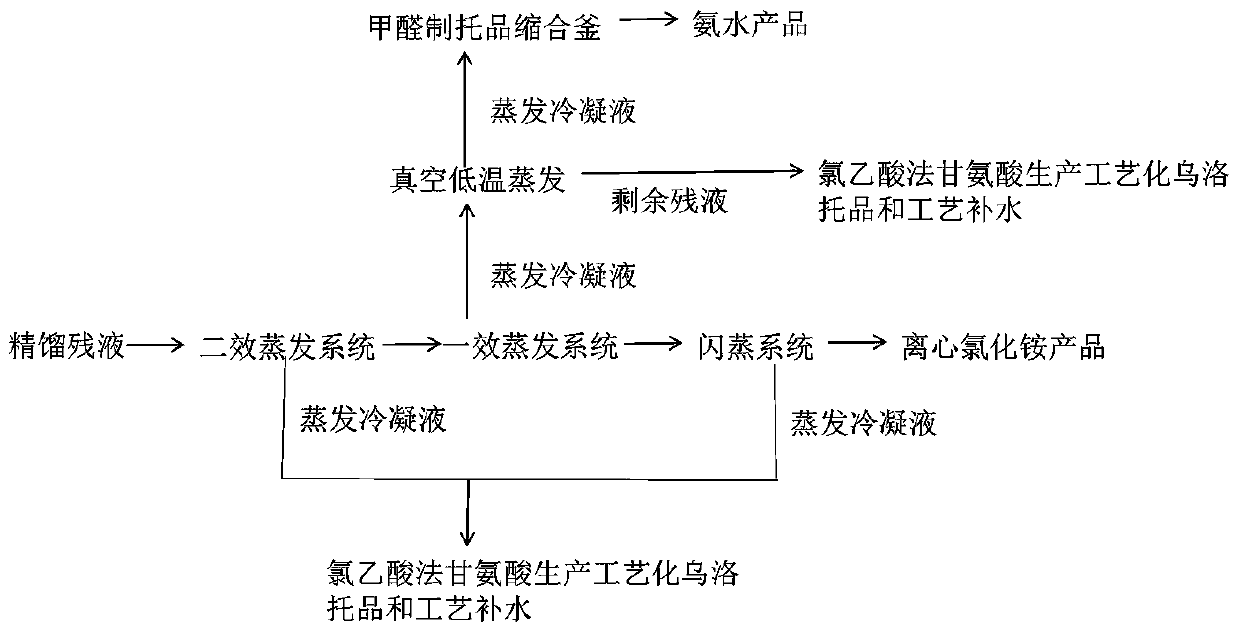

[0027] The production of 120 tons of glycine will produce 1560m³ of methanol mother liquor, of which the process water consumption is 140m³ (the sum of the water used for urotropine and the process water replenishment), and the residual liquor after the rectification of methanol produced by glycine is 230m³ of mother liquor, which are respectively evaporated by two effects After the system, the first-effect evaporation system and the decompression flash system, the temperature of the first-effect heater is controlled to 115°C, the vacuum degree is controlled to -0.06Mpa, the temperature of the first-effect evaporation condensate is 60°C, and the water volume is 80.53m³. The evaporation condensate volume of the two-effect evaporation system and the decompression flash evaporation system is 72.27m³, and the other water volume is 7.2m³ in the ammonium chloride product. The temperature of the first-effect evaporation condensate is 60°C, the water volume is 80.53m³, through vacuum l...

Embodiment 2

[0029] The production of 120 tons of glycine will produce 1560m³ of methanol mother liquor, of which the process water consumption is 140m³ (the sum of the water used for urotropine and the process water replenishment), and the residual liquor after the rectification of methanol produced by glycine is 230m³ of mother liquor, which are respectively evaporated by two effects After the system, the first-effect evaporation system and the decompression flash system, the temperature of the first-effect heater is controlled to 120°C, the vacuum degree is controlled to -0.08Mpa, the temperature of the first-effect evaporation condensate is 65°C, and the water volume is 86.2m³. The evaporation condensate volume of the two-effect evaporation system and the decompression flash evaporation system is 66.6m³, and the other water volume is 7.2m³ in the ammonium chloride product. The temperature of the first-effect evaporation condensate is 65°C, the water volume is 86.2m³, through vacuum low-...

Embodiment 3

[0031] The production of 120 tons of glycine will produce 1560m³ of methanol mother liquor, of which the process water consumption is 140m³ (the sum of the water used for urotropine and the process water replenishment), and the residual liquor after the rectification of methanol produced by glycine is 230m³ of mother liquor, which are respectively evaporated by two effects After the system, the first-effect evaporation system and the decompression flash system, the temperature of the first-effect heater is controlled to 130°C, the vacuum degree is controlled to -0.08Mpa, the temperature of the first-effect evaporation condensate is 75°C, and the water volume is 82.55m³. The evaporation condensate volume of the two-effect evaporation system and the decompression flash evaporation system is 74.85m³, and the other water volume is 7.2m³ in the ammonium chloride product. The temperature of the first-effect evaporation condensate is 55°C, the water volume is 82.55m³, through vacuum l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com