Reagent purification device and method for purifying ammonium bifluoride or ammonium fluoride by using same

A technology of ammonium bifluoride and ammonium fluoride, which is applied in the field of chemical analysis, can solve the problems that affect the purification efficiency, only a small amount of outflow, and the blockage of the condensation pipe, and achieve the effect of simple equipment principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

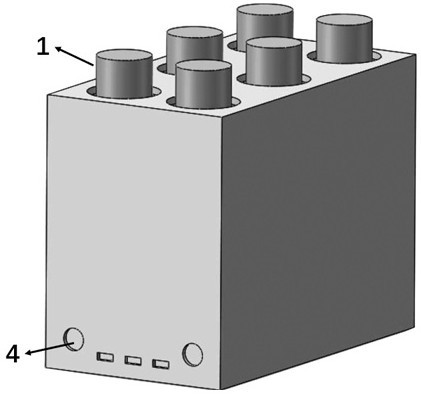

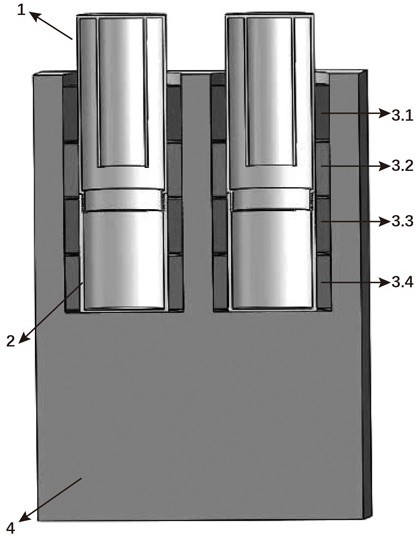

[0028] Ammonium bifluoride is purified by using the above-mentioned purification device in this embodiment.

[0029] (1) The initial NH 4 HF 2 Place in the cleaned reagent heating bottle, fill the reagent bottle with about one-third (about 150g), and can fill six reagent heating bottles (about 900 g) at a time; (2) Put the washed reagent collection bottle with the reagent The heating bottle is tightened by the knob, and then the six reagent heating bottles and reagent collection bottle assemblies are placed in the heating hole, with the reagent heating bottles facing down and the reagent collecting bottle facing up; (3) Turn on the power switch of the heating Each heating block is adjusted to 230 degrees Celsius, NH 4 HF 2 The vapor moves upwards and quickly crystallizes at the bottom of the reagent collection bottle; (4) After 20 minutes, adjust the temperature of the heating module 3.1 to 0, NH 4 HF 2 The steam crystallizes at the position of heating module 3.1; (5) Aft...

Embodiment 2

[0031] In this example, the ammonium fluoride was purified by using the above-mentioned purification device.

[0032] (1) The initial NH 4 F is placed in the cleaned reagent heating bottle and fills up about one-third of the reagent bottle (about 150g), and six reagent heating bottles (about 900 g) can be filled at one time; (2) Put the washed reagent collection bottle with The reagent heating bottle is tightened by the knob, and then the six reagent heating bottles and reagent collection bottle assemblies are placed in the heating hole, the reagent heating bottle is down, and the reagent collection bottle is facing up; (3) Turn on the power switch of the heating device, put All four heating modules are adjusted to 240 degrees Celsius, NH 4 F vapor moves upwards and quickly crystallizes at the bottom of the reagent collection bottle; (4) After 20 minutes, adjust the temperature of the heating module 3.1 to 0, NH 4 F vapor crystallizes at the position of heating module 3.1; (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com