Method for producing high-purity ammonium fluoride by utilizing sodium hydride waste residues

A technology of sodium hydrogen fluoride and ammonium fluoride, applied in the directions of ammonium fluoride, ammonium halide, alkali metal fluoride, etc., to achieve the effects of controllable reaction conditions, low production cost, comprehensive utilization and green production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

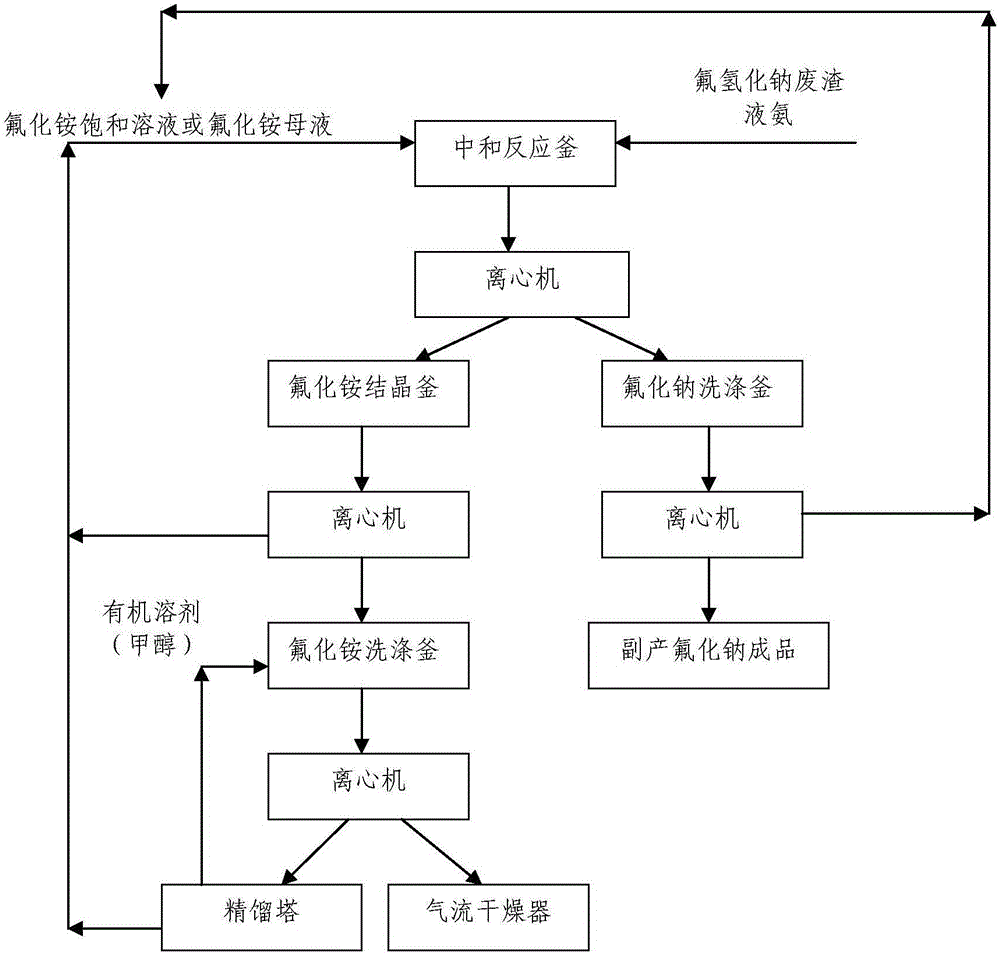

Method used

Image

Examples

Embodiment 1-1

[0039] Embodiment 1-1, a kind of method utilizing sodium bifluoride waste residue to produce high-purity ammonium fluoride, carries out following steps successively:

[0040] 1), put 200 kg of sodium bifluoride solid waste residue into the reactor, add 1000 liters of ammonium fluoride saturated solution, start stirring, and obtain sodium bifluoride slurry I;

[0041] 2), under stirring, slowly pass ammonia gas (obtained from gasification of liquid ammonia) into the sodium bifluoride slurry I obtained in step 1) until the pH is 8.0, then stop passing ammonia gas;

[0042] Control the speed during the process of passing ammonia gas, so as to control the temperature of the material between 70 and 80 °C;

[0043] 3), suction filter the material obtained in the reaction of step 2) while it is hot (78° C.) to obtain 1050 liters of ammonium fluoride solution I and 135 kg of crude sodium fluoride I;

[0044] 4), step 3) obtained 135 kg of crude sodium fluoride Ⅰ with 65 liters of boi...

Embodiment 1-2

[0051] Embodiment 1-2, a kind of method utilizing sodium bifluoride waste residue to produce high-purity ammonium fluoride, carries out following steps successively:

[0052] 1), put 200 kg of sodium bifluoride solid waste residue into the reactor, add 1000 liters of the ammonium fluoride mother liquor described in step 9) of Example 1-1, start stirring, and obtain sodium bifluoride slurry I;

[0053] 2), under stirring, slowly pass ammonia gas (obtained from gasification of liquid ammonia) into the sodium bifluoride slurry I obtained in step 1) until the pH is 8.0, then stop passing ammonia gas;

[0054] Control the speed during the process of passing ammonia gas, so as to control the temperature of the material between 70 and 80 °C;

[0055] 3), suction filter the material obtained in the reaction of step 2) while it is hot (79° C.), to obtain 1050 liters of ammonium fluoride solution I and 134 kg of crude sodium fluoride I;

[0056] 4), 134 kg of crude product sodium fluor...

Embodiment 2

[0063] Embodiment 2, a kind of method utilizing sodium bifluoride waste residue to produce high-purity ammonium fluoride, carries out following steps successively:

[0064] 1), put 200 kg of sodium bifluoride solid waste residue into the reactor, add 800 liters of the ammonium fluoride mother liquor described in step 9) of Example 1-1, start stirring, and obtain sodium bifluoride slurry I;

[0065] 2), under stirring, slowly pass ammonia gas (obtained from gasification of liquid ammonia) into the sodium bifluoride slurry I obtained in step 1) until the pH is 8.5, then stop passing ammonia gas;

[0066] Control the speed during the process of passing ammonia gas, so as to control the temperature of the material between 70 and 80 °C;

[0067] 3), the material obtained in the reaction of step 2) was filtered while hot (80° C.) to obtain 860 liters of ammonium fluoride solution I and 143 kg of crude sodium fluoride I;

[0068] 4), step 3) gained 143 kilograms of crude product sod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com