High active no-clean welding flux

A no-cleaning, flux technology, applied in welding media, welding equipment, welding/cutting media/materials, etc., can solve the problems of insufficient welding flux, low brazing seam strength, and many welding defects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

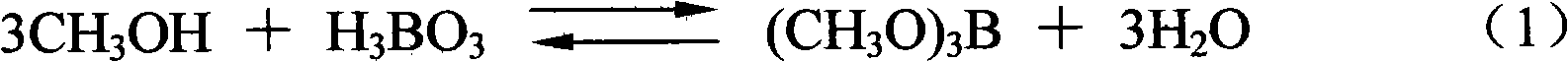

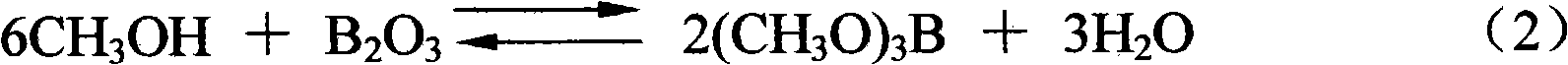

Method used

Image

Examples

Embodiment 1

[0031] A kind of highly active no-clean flux, proportioning by mass fraction, its composition is: 45.0% trimethyl borate ((CH 3 O) 3 B), 10.0% acetone (CH 3 COCH 3 ), 0.001% cesium fluoride (CsF), 0.001% diethyl ether (CH 3 CH 2 O CH 2 CH 3 ), the balance being methanol (CH 3 OH).

[0032] The high-activity no-clean flux obtained by the above ratio has a density (20°C) in the range of 0.855-0.891, a boiling point range of 52°C-56°C, and is passed through the flux "generator" through gas (acetylene gas, liquefied petroleum gas, propane and other combustible gases) ) is added (into) the torch in the form of steam, mixed with oxygen, burned, and brazed (flame welding). Test according to GB / T 11363-2008 "Brazed Joint Strength Test Method", with T 2 Red copper and H62 brass were used as the test base material, and the commercially available B-Cu93P solder was used as the test solder. The "effective" brazing area increased by 8% and 9.5% respectively, and the strength of th...

Embodiment 2

[0034] A kind of highly active no-clean flux, proportioning by mass fraction, its composition is: 45.0% trimethyl borate ((CH 3 O) 3 B), 10.0% acetone (CH 3 COCH 3 ), 0.001% rubidium fluoride (RbF), 0.001% diethyl ether (CH 3 CH 2 O CH 2 CH 3 ), the balance being methanol (CH 3 OH).

[0035] The high-activity no-clean flux obtained by the above ratio has a density (20°C) in the range of 0.855-0.891, a boiling point range of 52°C-56°C, and is passed through the flux "generator" through gas (acetylene gas, liquefied petroleum gas, propane and other combustible gases) ) is added (into) the torch in the form of steam, mixed with oxygen, burned, and brazed (flame welding). Test according to GB / T 11363-2008 "Brazed Joint Strength Test Method", with T 2 Red copper and H62 brass were used as the test base material, and the commercially available B-Cu93P solder was used as the test solder. The "effective" brazing area increased by 8% and 9.5% respectively, and the strength of ...

Embodiment 3

[0037] A kind of highly active no-clean flux, proportioned by mass fraction, its composition is: 80.0% trimethyl borate ((CH 3 O) 3 B), 0.01% acetone (CH 3 COCH 3 ), 1.0% cesium fluoride (CsF), 2.5% diethyl ether (CH 3 CH 2 OCH 2 CH 3 ), the balance being methanol (CH 3 OH).

[0038] The high-activity no-clean flux obtained by the above ratio has a density (20°C) in the range of 0.855-0.891, a boiling point range of 52°C-56°C, and is passed through the flux "generator" through gas (acetylene gas, liquefied petroleum gas, propane and other combustible gases) ) is added (into) the torch in the form of steam, mixed with oxygen, burned, and brazed (flame welding). Test according to GB / T 11363-2008 "Brazed Joint Strength Test Method", with T 2 Red copper and H62 brass were used as the test base metal, and the commercially available B-Cu93P solder was used as the test solder. The "effective" brazing area increased by 9.5% and 10.5% respectively, and the strength of the braz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com