A kind of process of industrialized continuous removal of alkaline impurities in sebs glue or sbs glue

A glue solution and process technology, applied in the field of preparation of polymer SEBS or SBS materials, can solve the problems of long residence time requirement, low catalyst removal efficiency, difficult removal of lower fatty alcohol, etc., and achieve good removal effect, The effect of continuous and efficient removal and increased exposure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

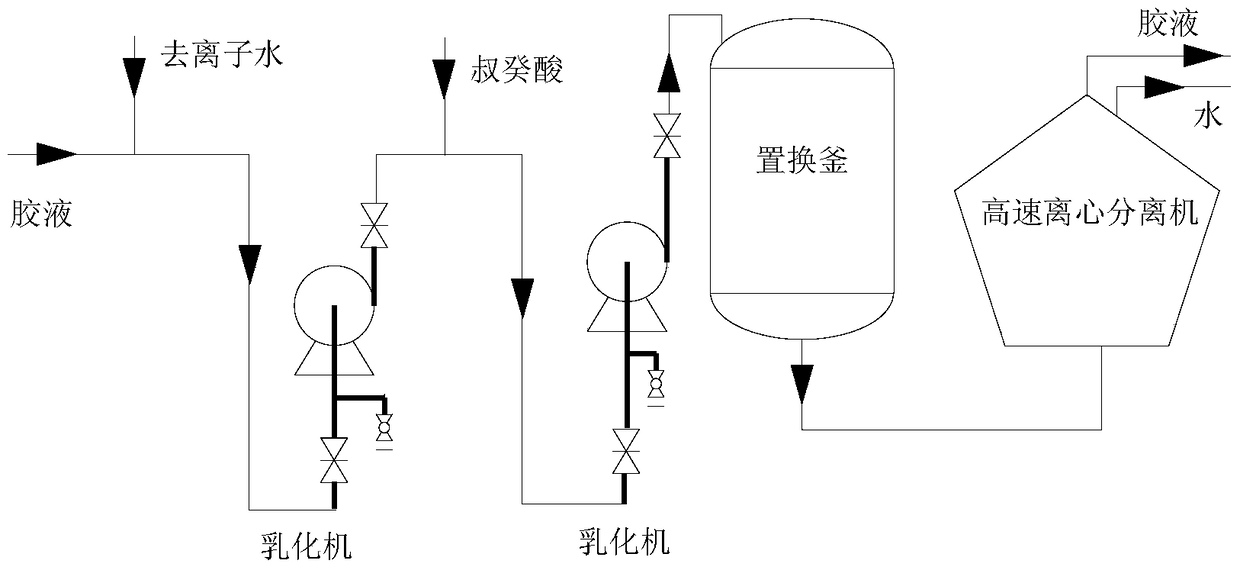

[0022] Continuously add deionized water and SEBS glue into the first pipeline type high-speed shearing emulsifier to fully shear and emulsify, control the amount of deionized water added to be 8% to 10% of the volume of SEBS glue, and the mixed solution and The continuously added tert-decanoic acid enters into the second pipeline type high-speed shearing emulsifier to fully shear and emulsify. The molar ratio of the carboxyl group of tert-decanoic acid to the lithium ion in the glue is 0.6-0.9:1, and the dispersed mixed solution Input it into the replacement kettle, and react for 20-30 minutes under the action of stirring. The generated lithium salt of tert-decanoate is dissolved in the water phase, and the mixed phase output from the replacement kettle is separated by a high-speed centrifuge to separate the water phase and the glue liquid phase. Thereby obtain SEBS glue and aqueous phase after impurity removal; Described the first pipeline type high-shear emulsifier, the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com