Chemical process wet-method desulphurization technology

A wet desulfurization and chemical separation technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of high cost and large consumption of desulfurizers, and achieve the effect of improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0094] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0095] For better illustrating the present invention, facilitate understanding technical scheme of the present invention, typical but non-limiting embodiment of the present invention is as follows:

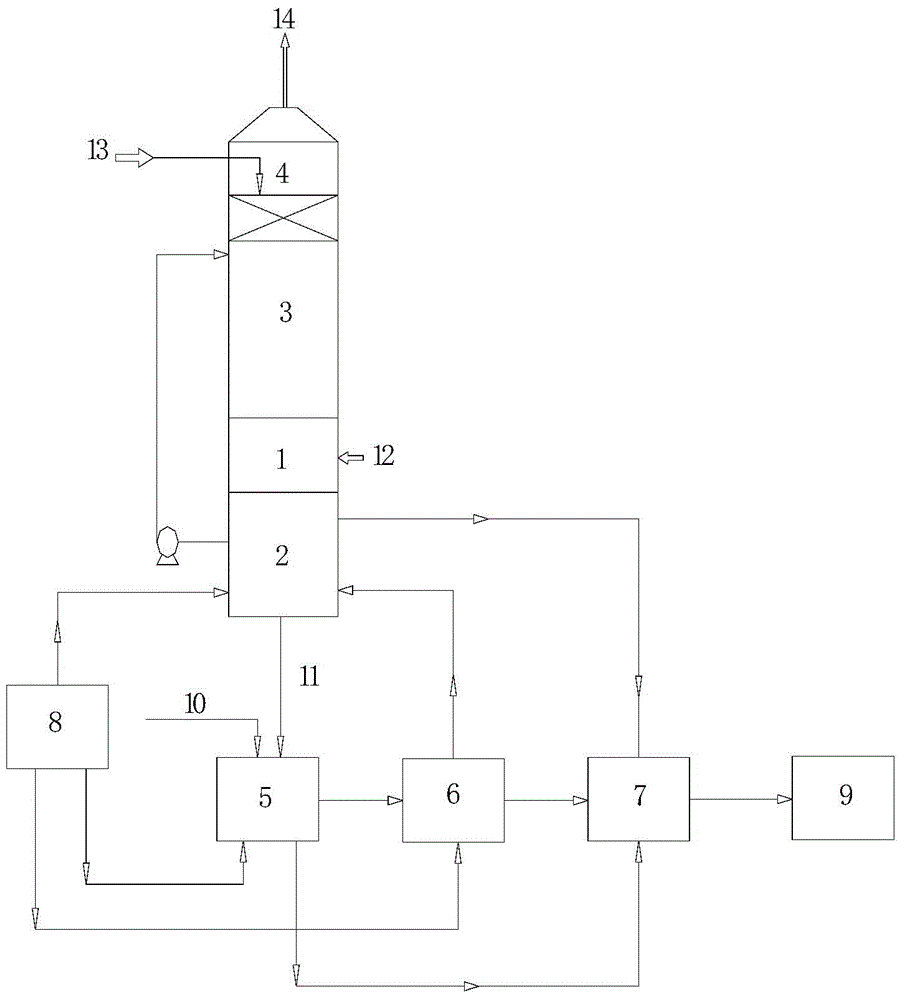

[0096] Such as figure 1 Shown, a kind of subchemical process wet desulfurization process, described process comprises absorption tower 1, and described absorption tower 1 is divided into circulation area 2, absorption area 3 and defogging area 4 from bottom to top, and described process comprises the following step:

[0097] 1) After grinding the alkaline waste residue, 90% of the solid particles pass through a 200-250 mesh sieve, prepare a slurry with water as a desulfurizer, transport it to the absorption tower circulation area 2, and reach the spray layer nozzle of the absorption area 3 through a ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com