Premixed dry mortar

A technology of dry powder mortar and mortar, which is applied in the field of building materials, can solve the problems of large amount of yellow sand used, and achieve the effects of solving stacking problems, avoiding damage, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The invention is further illustrated by the following examples.

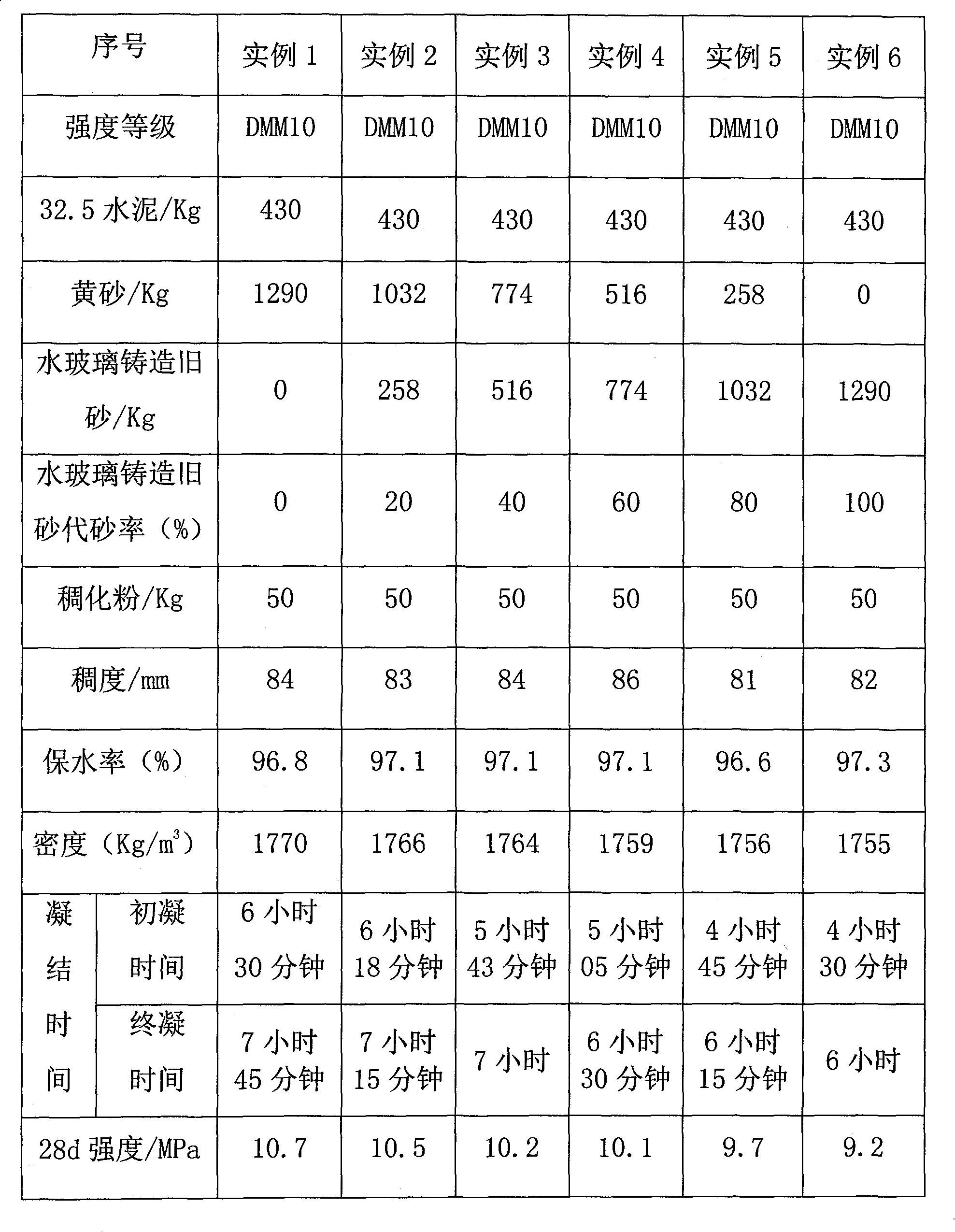

[0018] Examples 1-6, according to the mass ratio in Table 1, weigh different raw materials and mix evenly, add 17-22% water and stir evenly. The cement used in the test is 32.5 ordinary Portland cement, the fineness modulus of the yellow sand is 2.3, the fineness modulus of the used sand for sodium silicate casting is 1.9, and the fly ash is Class II ash.

[0019] From the test results in Table 1, it can be seen that with the increase of the amount of old sand used in water glass casting, the strength of dry powder mortar shows a downward trend. The replacement rate of old sand for water glass casting is below 60%, which has little influence on the strength and the working performance of the mortar.

[0020] Examples 7-12, according to the mass ratio in Table 2, weigh different raw materials and mix evenly, add 16-22% water and stir evenly. The cement used in the test is 42.5 ordinary Portland cement, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com