Interface mortar for autoclaved aerated concrete

A technology of interface mortar and autoclaved gas filling, which is applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of occupying agricultural land, environmental pollution, and prone to collapse accidents, and avoid damage , cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

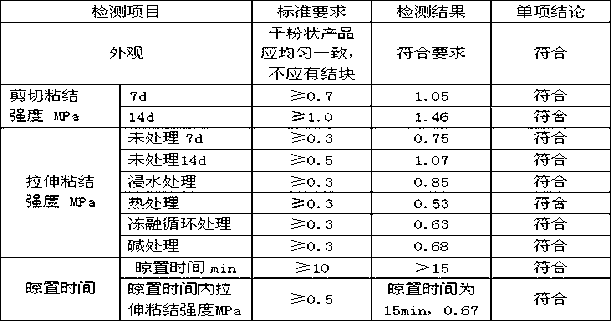

Image

Examples

Embodiment Construction

[0014] The hydroxypropyl methylcellulose ether of the present invention is 200000S sold by Zhejiang Kehong Chemical Co., Ltd., which has a good water retention and thickening effect and can significantly improve the construction performance of the interface mortar for autoclaved aerated concrete; the polyethylene Alcohol is produced by Shanghai Jinshan Petrochemical, specification 24-88; the redispersible latex powder is Wacker 5010N. The cement used in the present invention is P.O42.5R ordinary portland cement, and the selected yellow sand among the present invention is natural river sand, and its mud content is 0.9%, and fineness modulus is 1.5, and apparent density is 2540kg / m3. The tailing iron ore sand of the present invention is the waste residue produced by Zhejiang Litie Group Co., Ltd. in the mining and mineral processing process, and its main components are quartzite, diabase and granite. According to detection and analysis, the main component content is: TFe 8.12 %...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent density | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com