Automatic take-up and pay-off device and take-up and pay-off method for off-board direct-current charger

A technology of automatic take-up and take-up and charging machine, which is applied in the field of take-up and take-off, which can solve the problems of inconvenient dragging, damaged insulation, and scattered on the ground, etc., to achieve automatic take-up and take-up, prevent tightening and tearing, and prolong use The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings of the present invention.

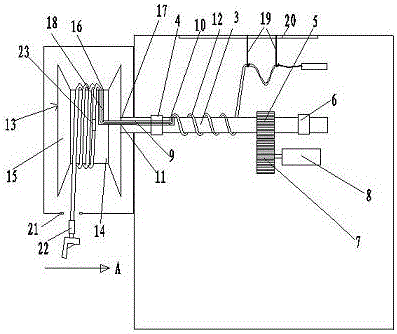

[0026] Such as figure 1 As shown in the present invention, an automatic take-up and release device for off-vehicle DC chargers includes a transmission mechanism, a winding reel 13 connected to the transmission mechanism and a charging cable 12, wherein the transmission mechanism is installed inside the charger, The winding reel 13 is installed at the end of the transmission mechanism and is located outside the charger. The outside of the winding reel 13 is covered with a casing 1, the casing 1 is fixed to the side wall of the charger, and an outlet 2 is arranged below the casing.

[0027] Specifically, the transmission mechanism includes a transmission shaft 3, a first bearing 4, a first gear 5, a second bearing 6, a second gear 7 and a transmission motor 8, wherein the first bearing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com