Cable winding device

A winding device and cable winding technology, applied in the mechanical field, can solve problems such as easy fatigue, inconvenient cables, and superimposed cables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to solve the inconvenient manual winding of the experimenter in the traditional low-temperature reliability test of cables, easy fatigue, frostbite hands, easy cable superposition, inaccurate test results caused by external temperature interference, and high and low temperature chambers that may be caused by external hot air impact To solve the problem of damage, a cable winding device is provided.

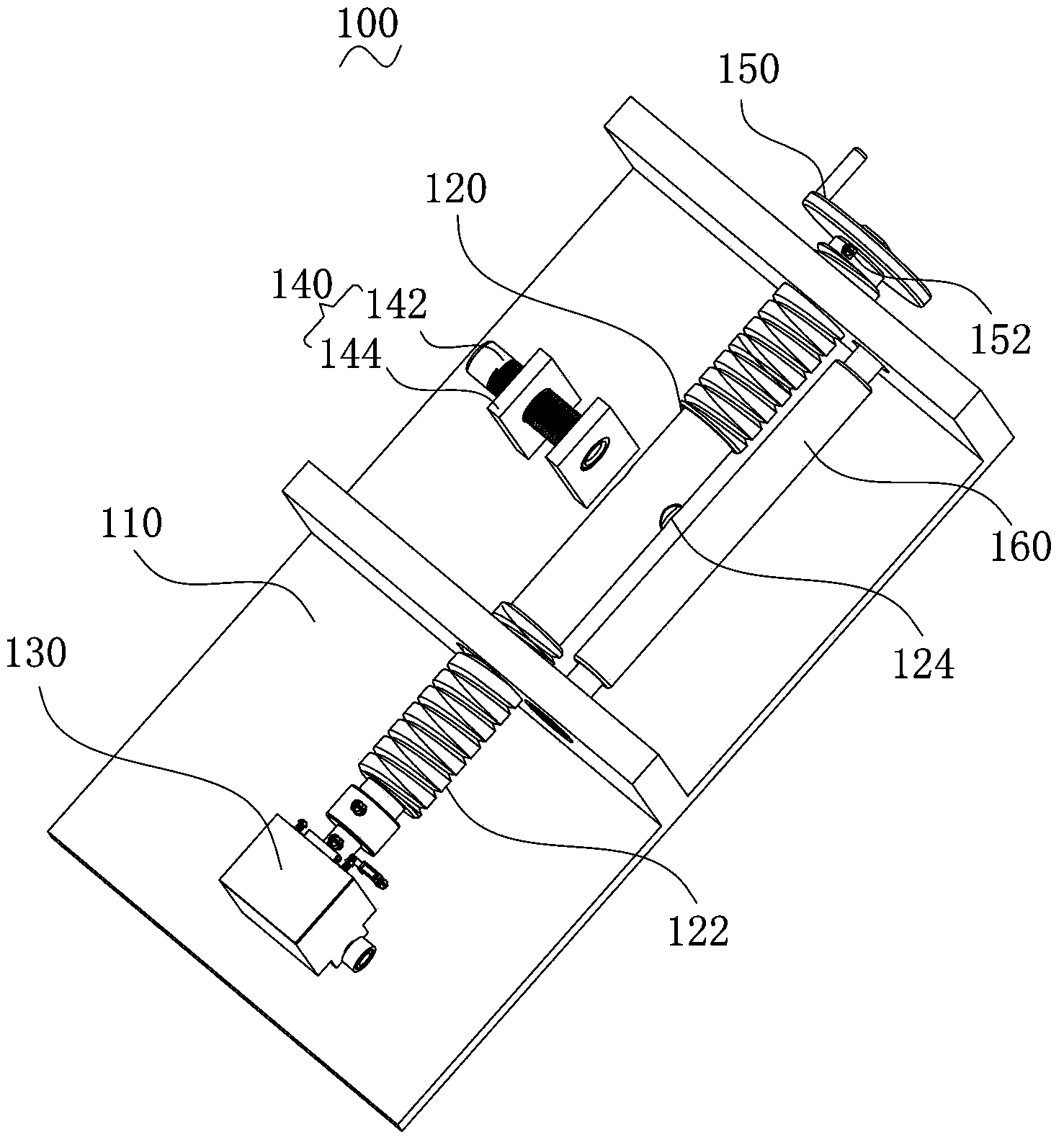

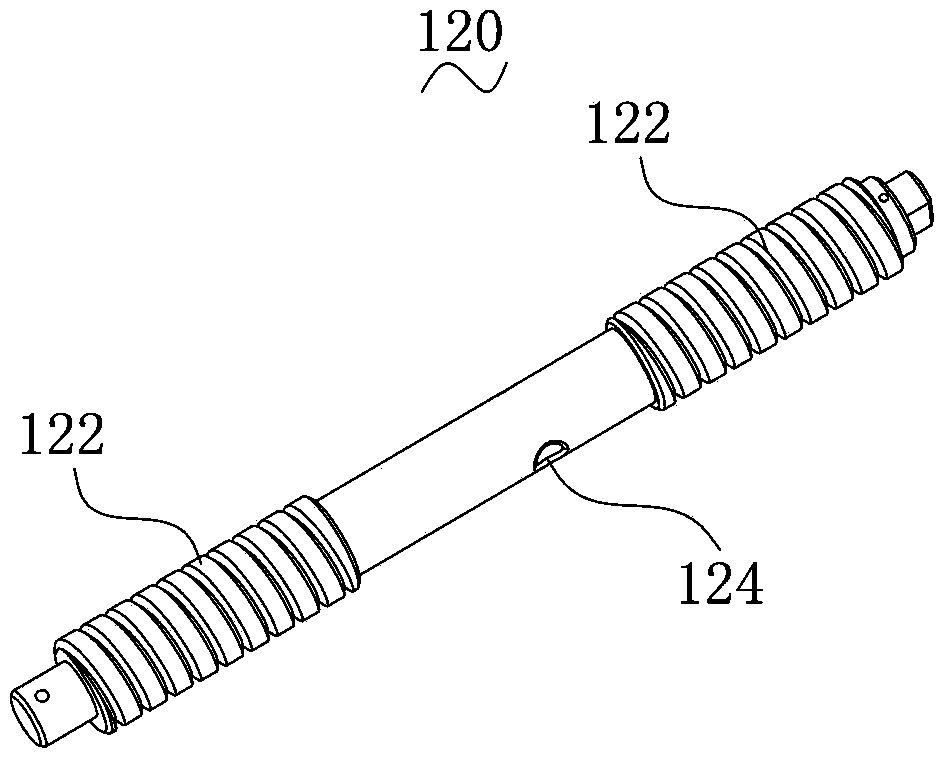

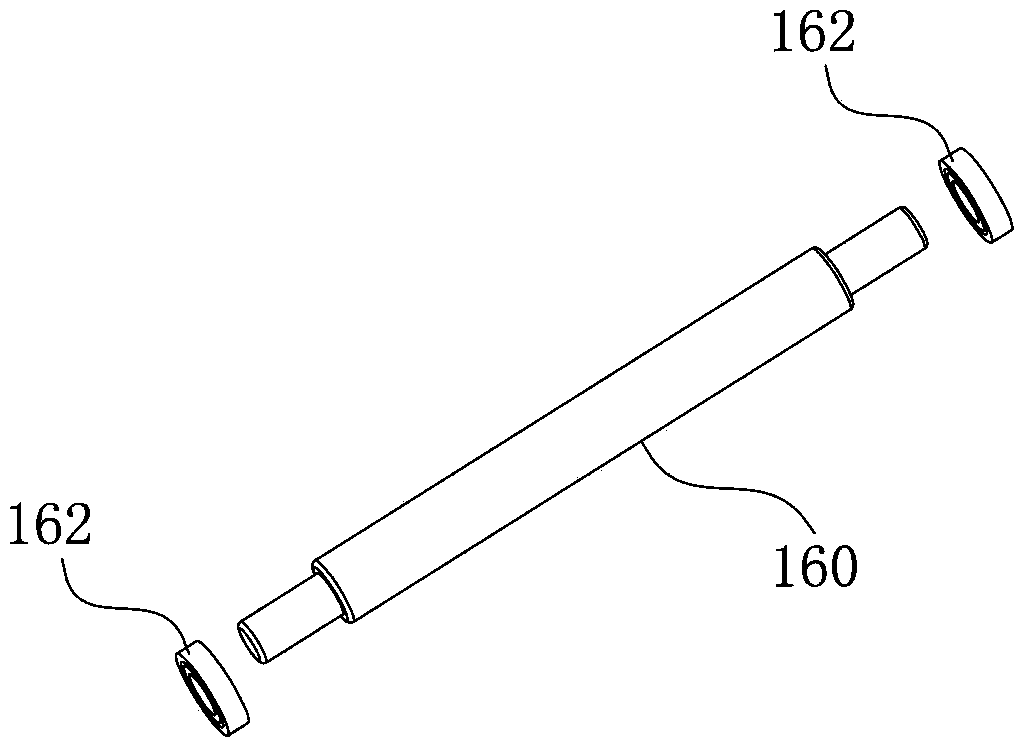

[0028] see also figure 1 and figure 2 As shown, the cable winding device 100 of an embodiment includes a bracket 110 , a winding rod 120 and a driving assembly 130 .

[0029] The bracket 110 is provided with threaded holes (not marked). As the carrier of the entire cable winding device 100 , it can keep the cable winding device 100 stable. Generally, the bracket 110 includes a bottom plate and a support plate. In order to ensure that the winding rod 120 can be evenly stressed to avoid excessive local stress, figure 1 Two support plates perpendicular to the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com