Full-automatic multi-station double-wire diameter winding machine and using method thereof

A multi-station, fully automatic technology, applied in the manufacture of motor generators, electromechanical devices, electric components, etc., can solve problems such as low work efficiency, difficulties in use and maintenance, and different diameters of fully automatic winding wires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

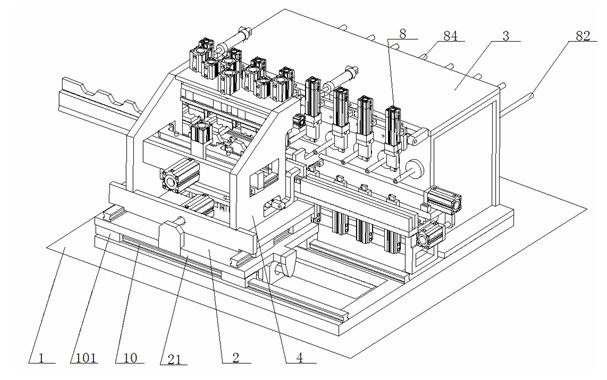

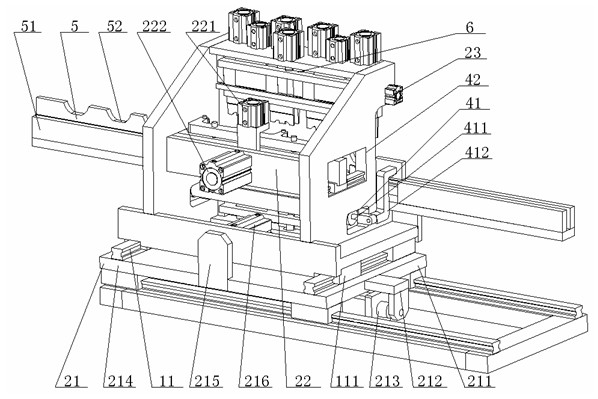

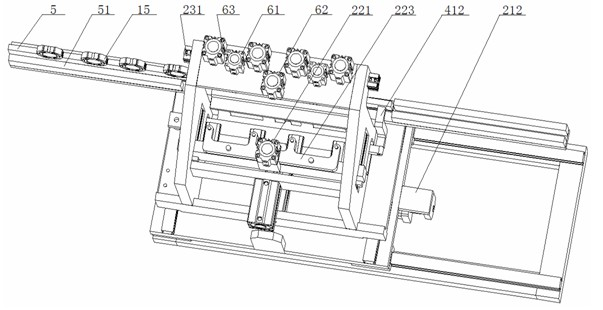

[0095] Taking four stations as an example, that is, a fully automatic four-station double-diameter inner winding machine, it includes four main winding winding rods 82 and four secondary winding winding rods 84, the wire diameter of the main winding 81 is the same as that of the secondary winding The diameters of the wires 83 are different. The coils wound by the main winding wire 81 constitute two sets of main windings, and the coils wound by the auxiliary winding wire 83 constitute two sets of auxiliary windings.

[0096] see figure 1 – Figure 11 , a fully automatic four-station double-diameter inner winding machine, including a base 1, a stator fixed and moving device 2 and a stator winding and trimming device 3, the stator fixed and moving device 2 includes a sliding mechanical frame 4, a stator clip 5, The stator fixing part 6 and the No. 1 wire mold assembly hand 22, the stator winding and trimming device 3 include the drive case 7, the winding rod 8, the No. 2 wire mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com