Robot gripper for roll material

A robot gripper and robot technology, applied in the direction of manipulator, program-controlled manipulator, winding strip, etc., can solve the problems of high manufacturing cost, poor flexibility, low versatility, etc., to improve efficiency and quality, simple structure, flexible strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

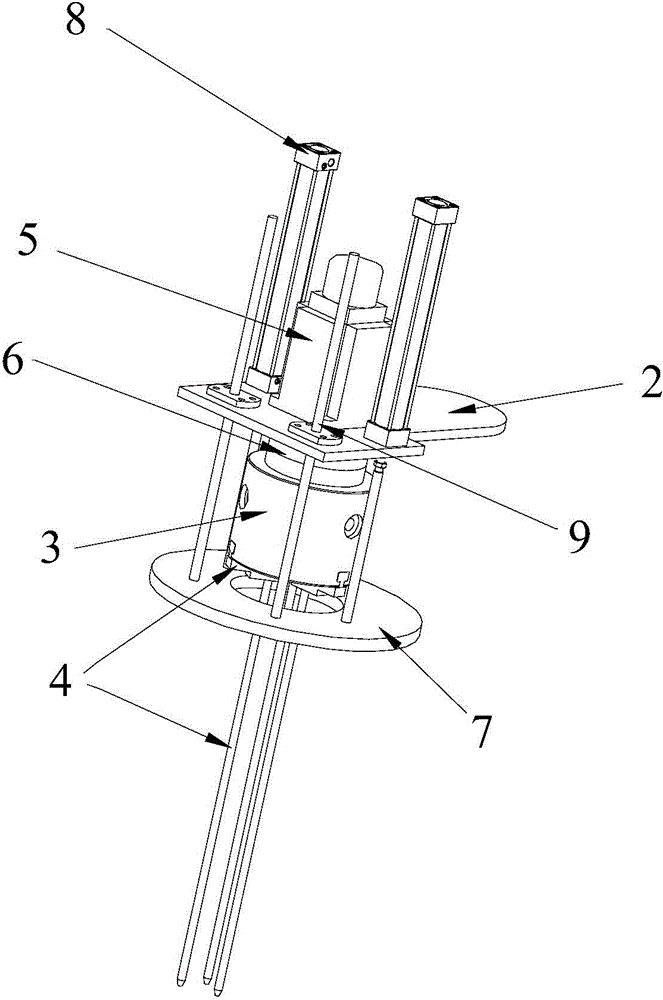

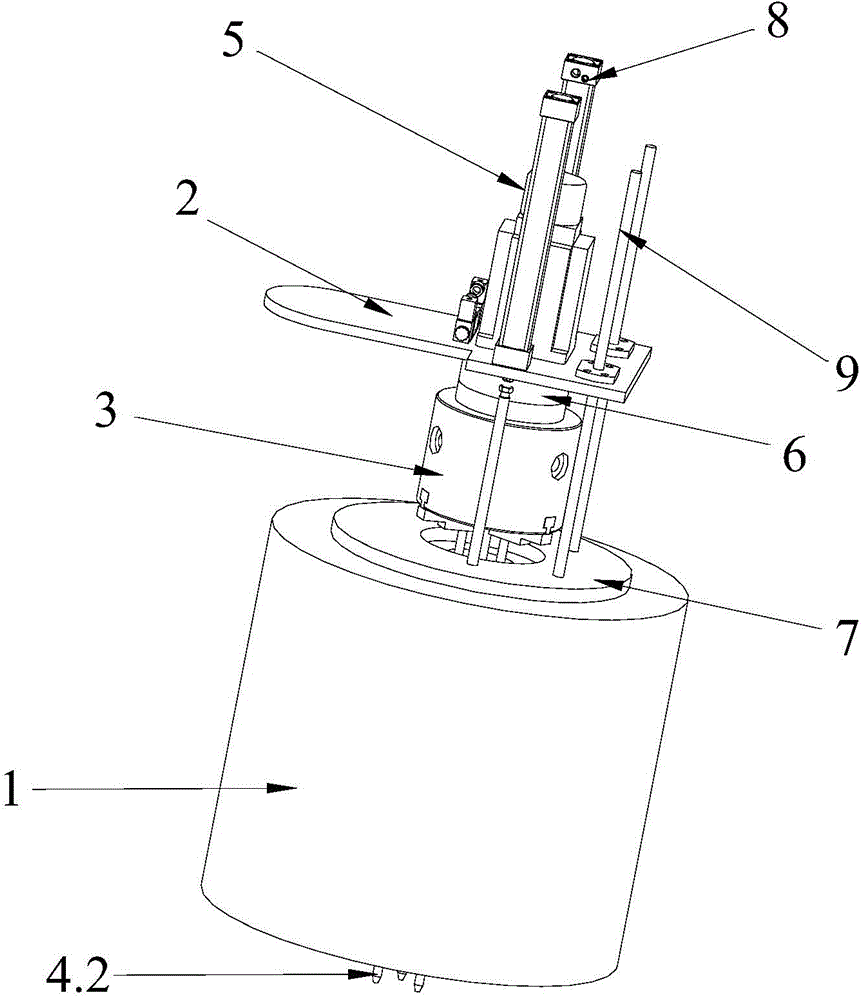

[0027] Such as Figure 1 to Figure 3 As shown, the robot gripper used for the coil material of the present invention is installed on the movable end of the robot, and is used to fix the coil material shaft 1 to wind the material. The robot gripper includes: a connecting plate 2 connected to the movable end of the robot, a fixing device for supporting the inner cavity of the coil shaft 1 to fix the coil shaft 1, and a driving device for driving the rotation of the fixing device; the driving device is arranged on the connection The plate 2 is connected with the fixing device to drive the fixing device to rotate to wind the material.

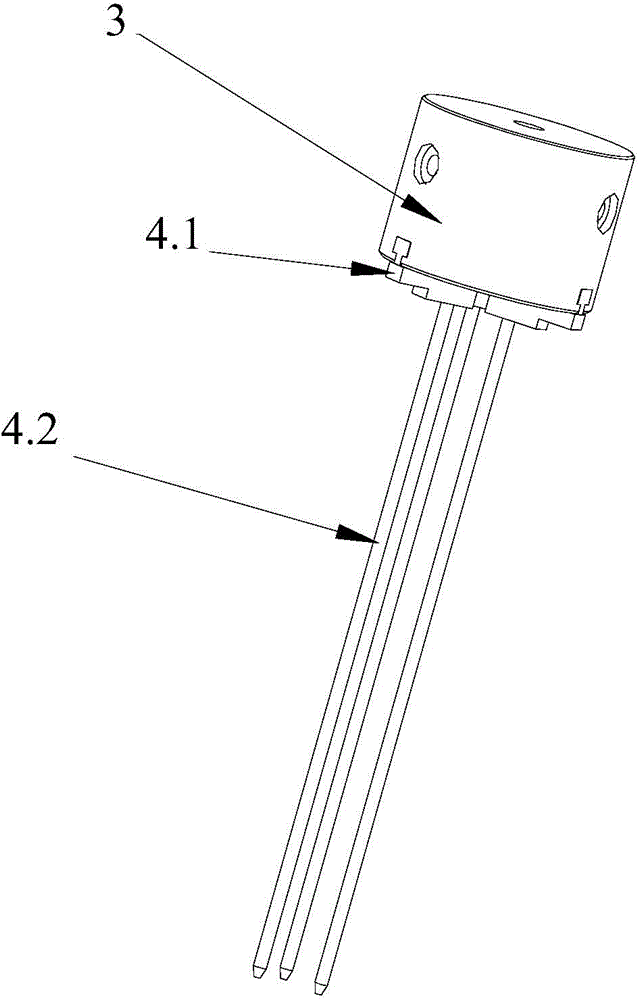

[0028] Wherein, the fixing device includes a main body 3, a claw 4 that is movably connected to one end surface of the main body 3, and a driving mechanism one, and the driving mechanism one is connected with the claw 4, and the driving claw 4 is stretched outward on the end surface of the main body 3 and toward the center of the main body. Retrac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com